Graphene modified ultralow-density propping agent and preparation method thereof

A graphene modification and ultra-low density technology, applied in chemical instruments and methods, earth drilling, mining fluids, etc., can solve problems such as limiting performance, achieve enhanced interface interaction, facilitate heat loss, and avoid brittleness Fracture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

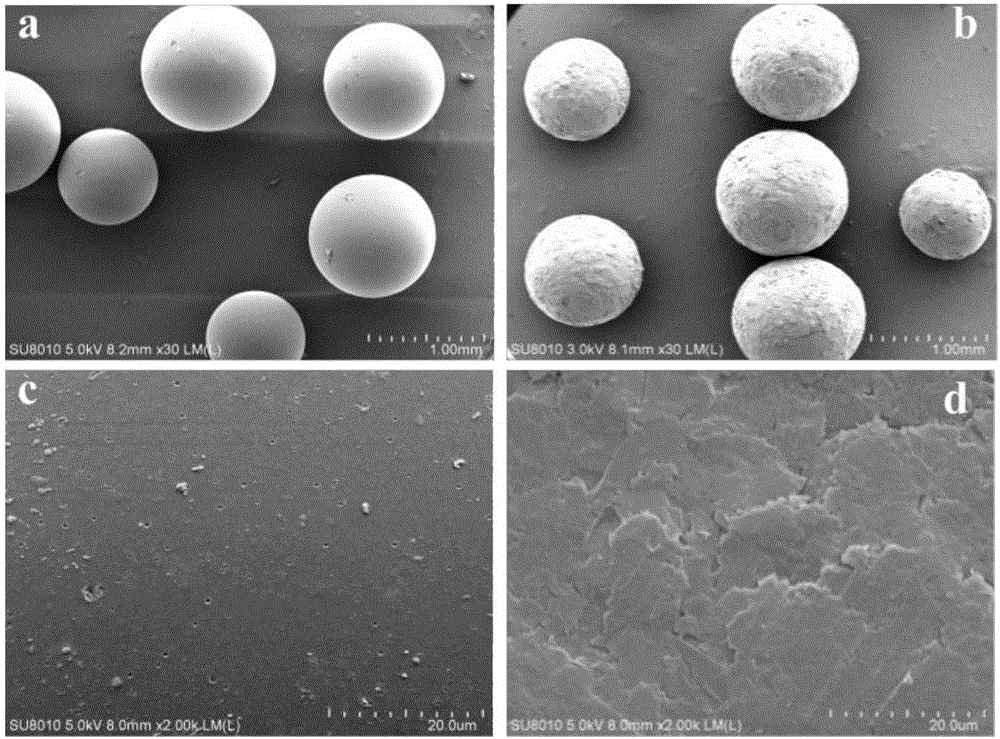

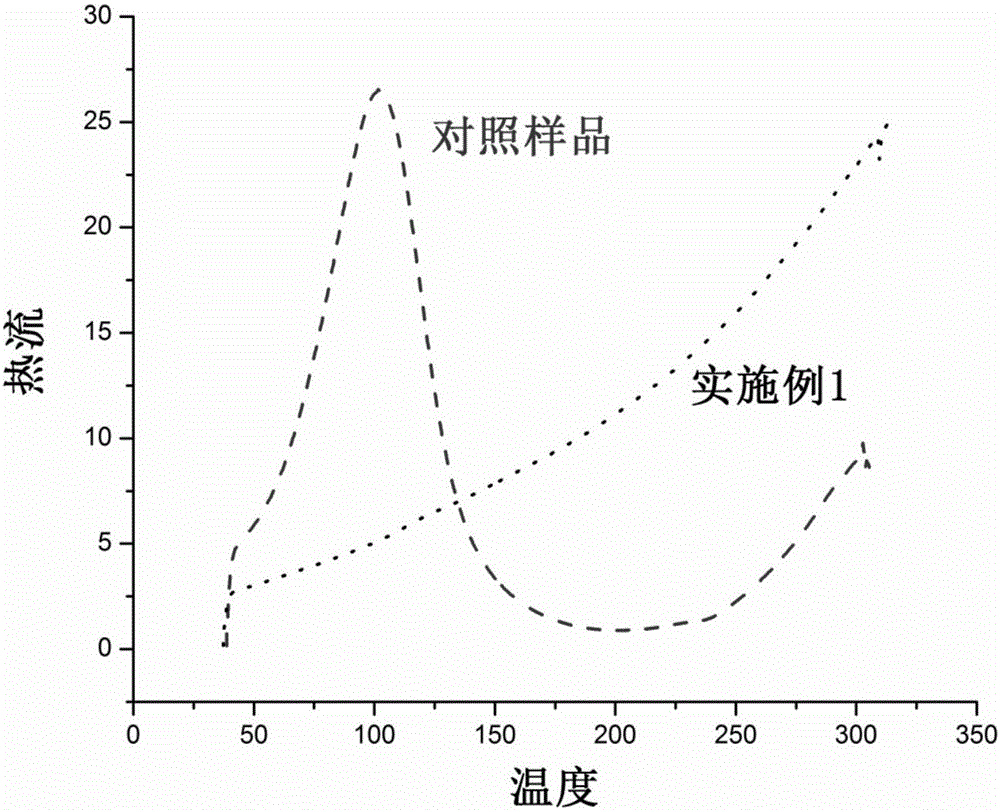

[0025] The graphene-modified ultra-low density proppant described in this embodiment is prepared by the following method:

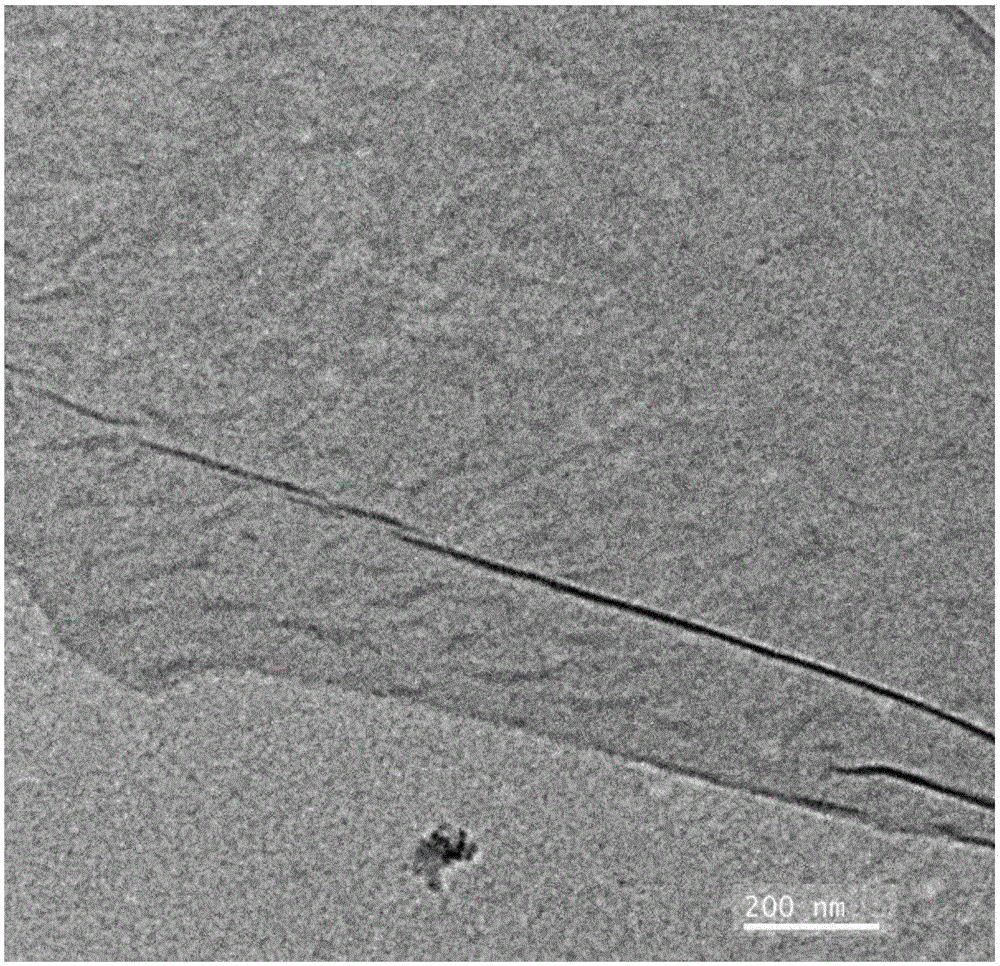

[0026] (1) 0.05g graphene (the lateral dimension is 5 μm, and the number of layers is 4 layers) is added to 30g styrene, 3g divinylbenzene, in the mixed solution of 0.3g benzoyl peroxide, stirs 30min to obtain graphene and Styrene and divinylbenzene form a monomer mixture of π-π assembly;

[0027] (2) Add the above-mentioned monomer mixture into 60 g of water in which 3 g of gelatin is dissolved, react under stirring conditions at 48°C for 45 minutes, at 78°C for 3 hours, and at 98°C for 45 minutes to obtain microsphere precipitation, filter, wash, and dry to obtain graphene-modified Ultra-low density proppant.

[0028] The control sample was polymer microspheres obtained without adding graphene under the same conditions.

Embodiment 2

[0030] The graphene-modified ultra-low density proppant described in this embodiment is prepared by the following method:

[0031] (1) Add 0.01g graphene (horizontal size is 0.3μm, the number of layers is 1 layer) to 20g styrene, 0.5g divinylbenzene, 0.1g benzoyl peroxide mixed solution, ultrasonic 15min to get graphite A monomer mixture in which olefin forms π-π assembly with styrene and divinylbenzene;

[0032] (2) Add the above monomer mixture into 40g of water in which 0.5g of gelatin is dissolved, and react under stirring conditions at 45°C for 0.5h, at 75°C for 2h, and at 95°C for 0.5h to obtain microsphere precipitates, which are obtained after filtration, washing and drying Graphene modified ultra-low density proppants.

Embodiment 3

[0034] The graphene-modified ultra-low density proppant described in this embodiment is prepared by the following method:

[0035] (1) 0.1g graphene (the transverse dimension is 50 μm, and the number of layers is 10 layers) is added to 40g styrene, 5g divinylbenzene, in the mixed solution of 0.5g benzoyl peroxide, stirs 60min to obtain graphene and Styrene and divinylbenzene form a monomer mixture of π-π assembly;

[0036] (2) Add the above monomer mixture to 80 g of water in which 5 g of gelatin is dissolved, react under stirring conditions at 50°C for 0.5h, at 80°C for 4h, and at 100°C for 1h to obtain microsphere precipitation, filter, wash, and dry to obtain graphene Modified ultra-low density proppants.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com