Method for preparing biobased reinforcing filler by utilization of papermaking black liquor

A technology of papermaking black liquor and reinforcing filler, applied in the field of composite materials, can solve the problems of unsatisfactory reinforcement effect, poor heat resistance, easy water absorption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

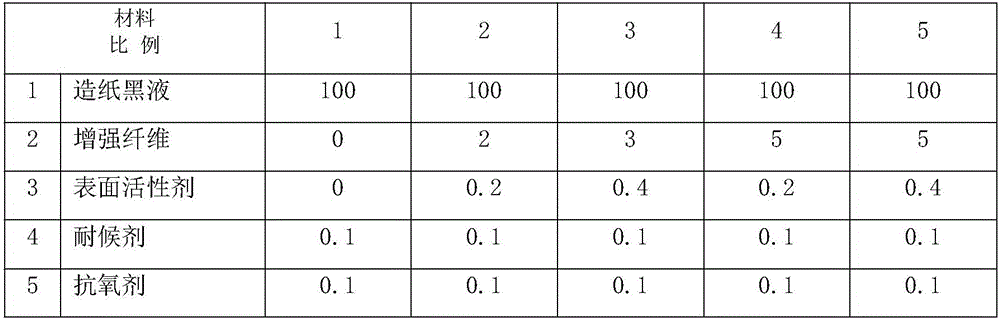

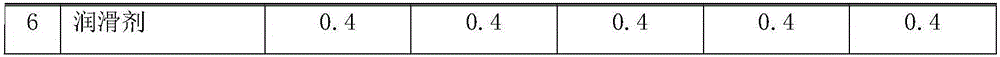

[0017] The method for preparing bio-based reinforcing filler by using papermaking black liquor in the present invention takes papermaking black liquor as the base material, wherein, 100 parts of papermaking black liquor; 2-6 parts of reinforcing fiber; 0.2-1 part of surfactant; weather resistance agent: 0.05-0.5 parts; antioxidant: 0.05-0.5 parts; lubricant: 0.2-1 parts. See Table 1 for details.

[0018] The embodiment of the present invention utilizes papermaking black liquor to prepare the method for bio-based reinforcing filler, and the steps are as follows:

[0019] Step 1. Take the papermaking black liquor, use the acid analysis method, through precipitation, drying, and grinding to form a lignin fiber powder filler with a particle size of 20-50 μm;

[0020] The papermaking black liquor is selected from one or two or more mixtures of papermaking black liquors produced by manufacturing wood pulp, straw pulp, hemp pulp, reed pulp, cane pulp, bamboo pulp, etc., preferably w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com