Preparation method of graphene heat conducting silica gel pad

A technology of thermally conductive silica gel and graphene, applied in graphene, heat exchange materials, chemical instruments and methods, etc., can solve the problems of low lateral thermal conductivity of thermally conductive silica gel pads, poor heat soaking effect, etc., and achieve heat soaking effect Good, enhanced heat soaking effect, high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The present invention is achieved like this, a kind of preparation method of graphene heat-conducting silica gel pad, comprises the following steps:

[0014] S01. Provide a metal foil, and grow a single-layer graphene film on the surface of the metal foil by chemical vapor deposition to obtain a graphene film / metal foil;

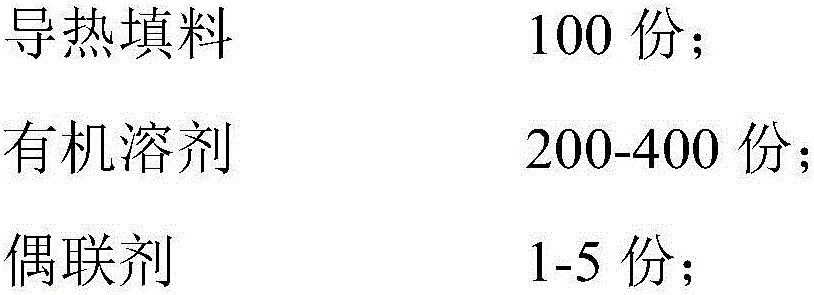

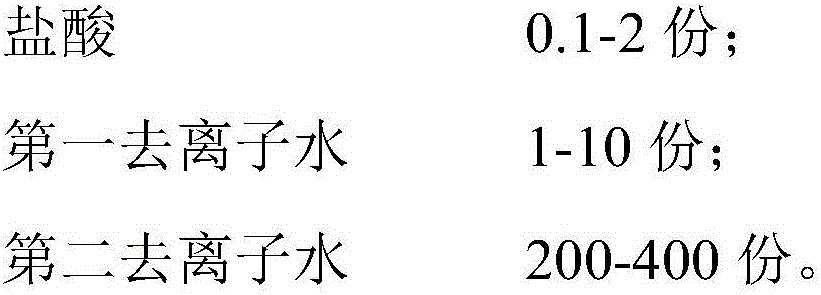

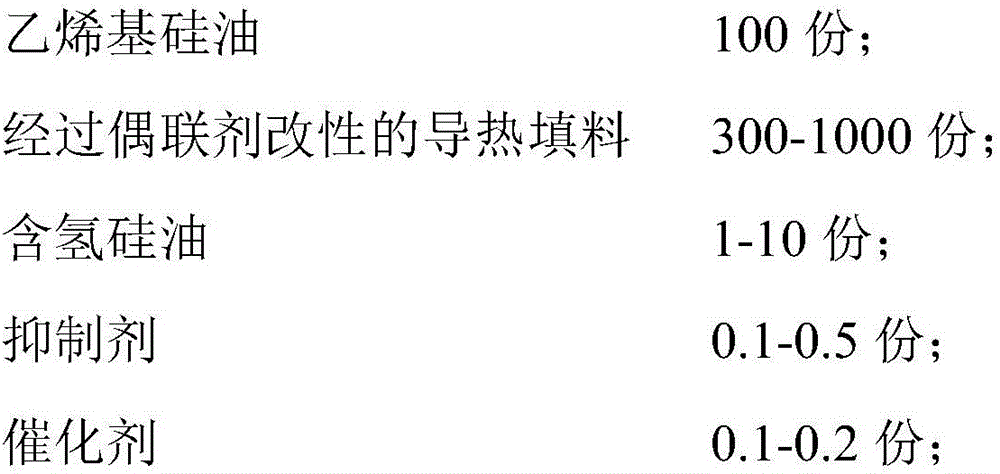

[0015] S02. Prepare the thermally conductive filler modified by the coupling agent. Mix the thermally conductive filler modified by the coupling agent, vinyl silicone oil, hydrogen-containing silicone oil, inhibitor and catalyst to form a mixed material. Press the sheet to prepare a thermally conductive silica gel pad;

[0016] S03. The graphene surface of the graphene film / metal foil is attached to the thermal release tape, and the graphene film / metal foil is placed in an etching solution until the metal foil is completely dissolved to obtain graphite Graphene film / thermal release tape; After rinsing and drying the graphene film / thermal release tape...

Embodiment 1

[0043] A preparation method for a graphene thermally conductive silica gel pad, comprising the following steps:

[0044] S11. Growth of graphene film

[0045] Put the copper foil in a chemical vapor deposition furnace, feed methane and hydrogen at 1000°C and 0.1 Pa, the methane flow rate is 5 sccm, the hydrogen flow rate is 10 sccm, and grow for 5 minutes to obtain a copper foil with a graphene film.

[0046] S12. Preparation of thermally conductive silica gel pad

[0047] Mix a 1:1 mixture of 100g of aluminum oxide and graphene powder with 300g of ethanol, add 1g of deionized water, 1g of γ-aminopropyltriethoxysilane, and stir Add 0.1g of hydrochloric acid, continue to stir for 4 hours at a speed of 300rpm, filter and wash with water, then add 200g of deionized water, and spray dry to obtain a thermally conductive filler modified by a coupling agent; mix 100g of vinyl silicone oil, 1g of hydrogen-containing Silicone oil, 300g of thermally conductive filler modified by coupl...

Embodiment 2

[0051] A preparation method for a graphene thermally conductive silica gel pad, comprising the following steps:

[0052] S21. Growth of graphene film

[0053] Put the copper foil in a chemical vapor deposition furnace, feed methane and hydrogen at 1000°C and 0.1Pa, the methane flow rate is 5 sccm, the hydrogen flow rate is 10 sccm, and grow for 5 minutes to obtain a copper foil with a graphene film.

[0054] S22. Preparation of thermally conductive silicone pad

[0055] Mix a 1:1 mixture of 100g of aluminum oxide and graphene powder with 300g of ethanol, add 1g of deionized water, 1g of γ-aminopropyltriethoxysilane, and stir Add 0.1g of hydrochloric acid, continue to stir for 4 hours at a speed of 300rpm, filter and wash with water, then add 200g of deionized water, and spray dry to obtain a thermally conductive filler modified by a coupling agent; mix 100g of vinyl silicone oil, 1g of hydrogen-containing Silicone oil, 300g of thermally conductive filler modified by coupling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com