A battery module heating device and a battery module

A battery module and heating device technology, which is applied to battery/fuel cell control devices, battery pack components, secondary batteries, etc. Low efficiency and other problems, to achieve the effect of improving heat utilization, reducing occupied space, and improving energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

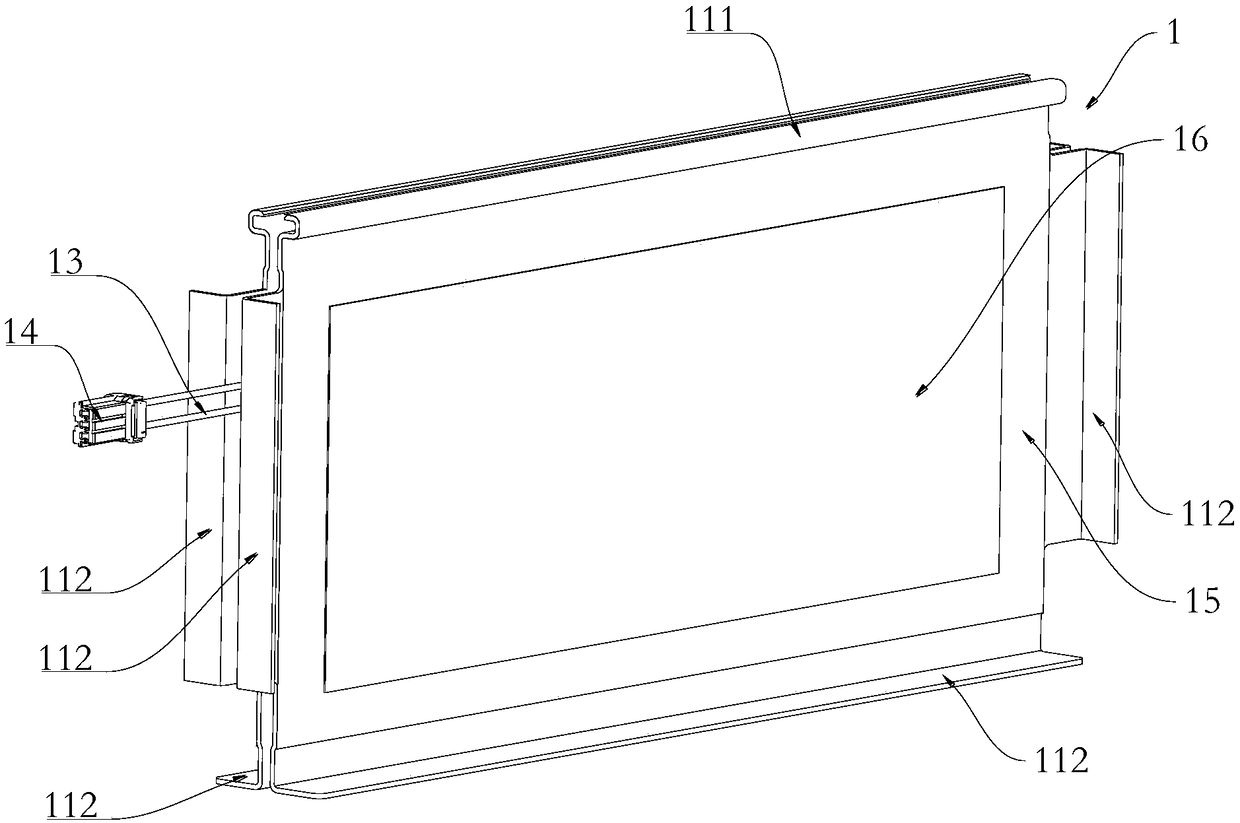

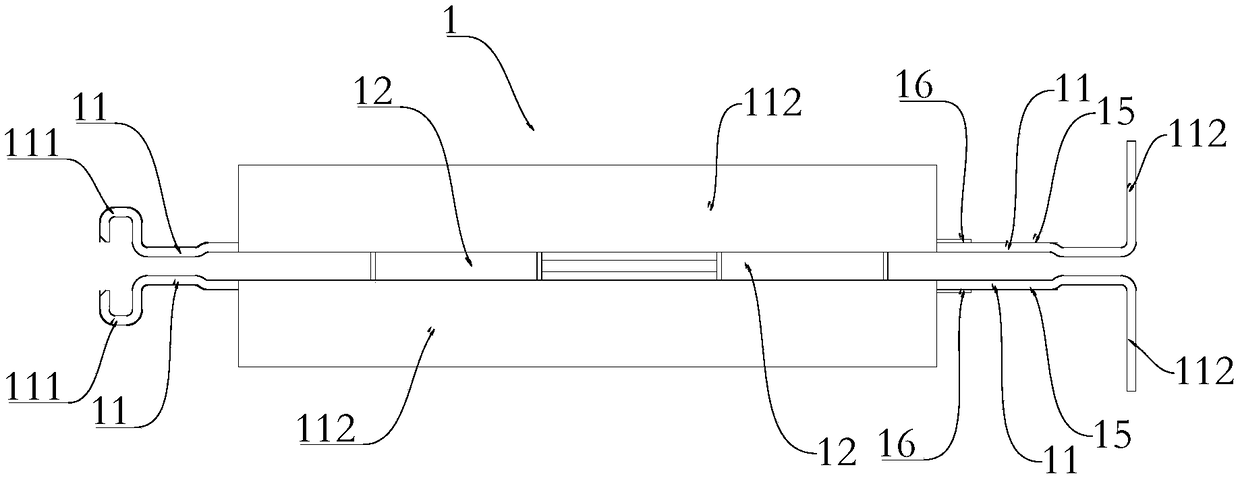

[0041] Such as figure 1 and figure 2 As shown, a heating device for a battery module in this embodiment includes two connecting plates 11 and a heating element 12, the two connecting plates 11 are arranged opposite to each other, and an installation The heating element 12 is located in the installation gap and is fixedly connected to the two connecting plates 11 respectively.

[0042] The connecting plate 11 of this embodiment is processed by a profile mold, and the material is 6 series aluminum, which has high strength and rigidity.

[0043] In the heating device of this embodiment, a heating element is arranged between the two connecting plates. When the heating device is used in a battery module, the two connecting plates can be heated respectively through the heating element, and then the heating element in contact with the connecting plates can be heated. The electric core is heated, so that the heat energy generated by the heating element can be absorbed by the electr...

Embodiment 2

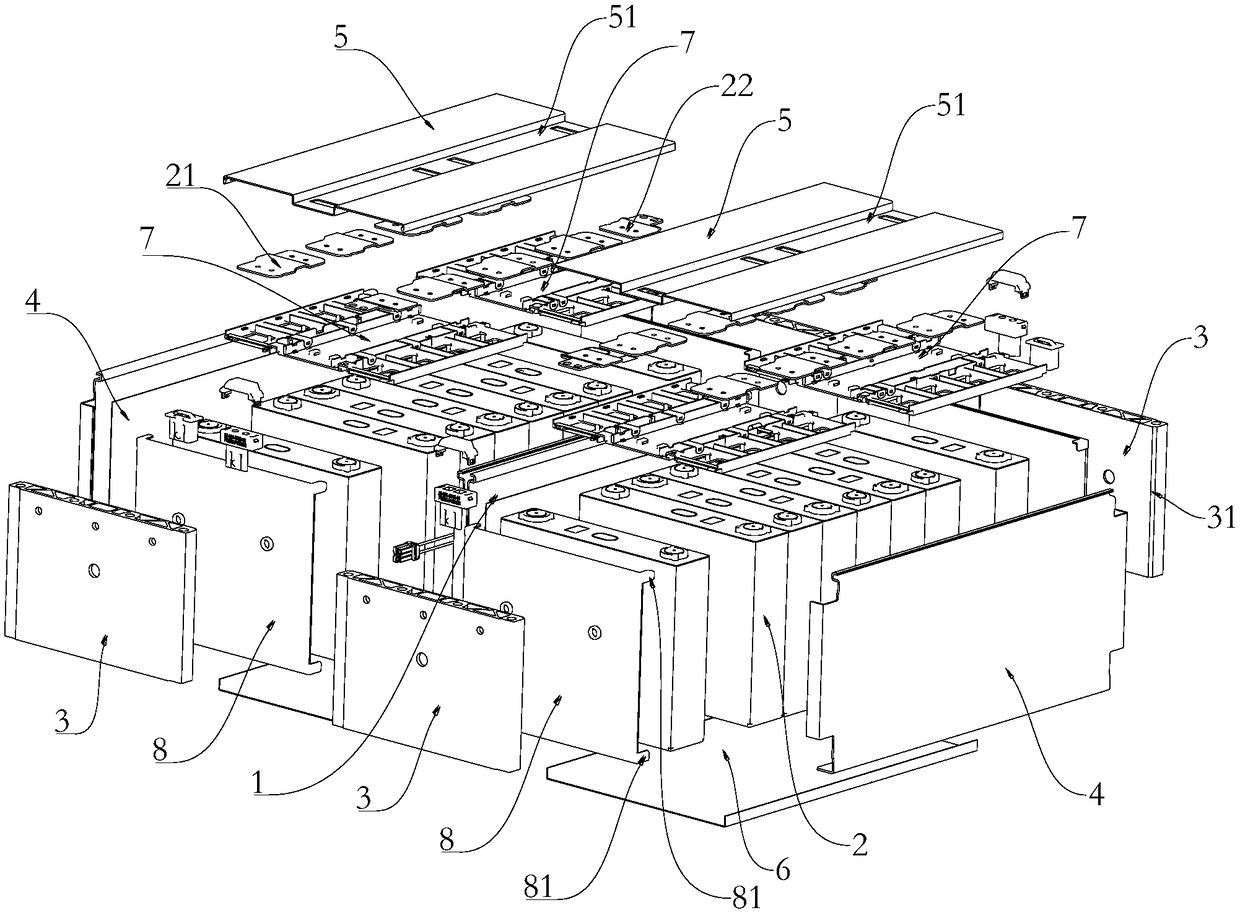

[0053] Such as image 3 As shown, a battery module in this embodiment includes a plurality of battery cells 2, a casing and the heating device, and a plurality of the battery cells 2 are arranged in multiple rows and installed in the casing, two adjacent rows The heating device 1 is installed between the battery cells 2, the side of the connecting plate 11 away from the heating element 12 is in contact with the end of a row of battery cells 2, and the connecting plate 11 is clamped with the casing .

[0054] In the battery module of this embodiment, a heating device is arranged between the two rows of cells, which can heat the two rows of cells at the same time, so that the heat of the heating device can be absorbed by the cells to the greatest extent, thereby improving the utilization rate of heat; The connecting plate is clamped with the shell, so that the heating device is installed more firmly, and the heating device is prevented from shaking in the battery module. Two r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com