Shoe sole material for antiskid wear-resistant sports shoes and preparation method thereof

A technology for sole materials and sports shoes, which is applied in the field of sole material formulations, can solve problems such as non-wear resistance, and achieve the effects of good wear resistance, high anti-slip coefficient, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The non-slip and wear-resistant sports shoe sole material of the present embodiment is made up of the raw material of following proportioning by weight:

[0041] Natural rubber, 60 parts; nylon short fiber (1mm), 1 part; long glass fiber (12mm), 2 parts; zinc oxide, 4 parts; 3-methacryloxypropyltrimethoxysilane, 1 part; Sulfur, 2 parts; Calcium Carbonate, 5 parts; Silica, 10 parts.

[0042] The preparation method of the anti-slip and wear-resistant sports shoes sole material of the present embodiment comprises the following steps:

[0043] Step 1, refining: mix natural rubber, nylon staple fiber, long glass fiber, zinc oxide, 3-methacryloxypropyltrimethoxysilane, and sulfur by weight and send them into the mill for refining , mill roll; distance 1mm, thin pass 10 times;

[0044] Step 2, internal mixing: send the mixed rubber material after the opening to the internal mixer for internal mixing, the temperature of the internal mixer is 105°C, and internal mixing for 4 t...

Embodiment 2

[0049] The non-slip and wear-resistant sports shoes sole material of the present embodiment is made of the following raw materials in parts by weight

[0050] Composition: Natural rubber, 50 parts; Nylon short fiber (3mm), 1 part; Long glass fiber (12mm), 3 parts; Zinc oxide, 5 parts; Vinyl trichlorosilane, 0.5 part; Sulfur, 2 parts; Calcium carbonate , 5 parts; silicon dioxide, 10 parts.

[0051] The preparation method of the non-slip and wear-resistant sports shoe sole material of this embodiment is the same as that of Embodiment 1, except that the coupling agent used in Step 1 is vinyltrichlorosilane.

[0052] The preparation method of the anti-slip and wear-resistant sports shoes sole material of the present embodiment comprises the following steps:

[0053] Step 1, refining: mix natural rubber, nylon staple fiber, long glass fiber, zinc oxide, 3-methacryloxypropyltrimethoxysilane, and sulfur by weight and send them into the mill for refining , mill roll; distance 1mm, t...

Embodiment 3

[0059] The non-slip wear-resisting sports shoes sole material of the present embodiment is made up of the raw material of following proportioning by weight: natural rubber, 40 parts; Nylon short fiber (3mm), 3 parts; Long glass fiber (25mm), 3 parts; Zinc oxide , 5 parts; 3-methacryloxypropyltrimethoxysilane, 0.5 parts; sulfur, 2 parts; calcium carbonate, 10 parts; silicon dioxide, 10 parts.

[0060] The preparation method of the anti-slip and wear-resistant sports shoes sole material of this embodiment is as in embodiment 1.

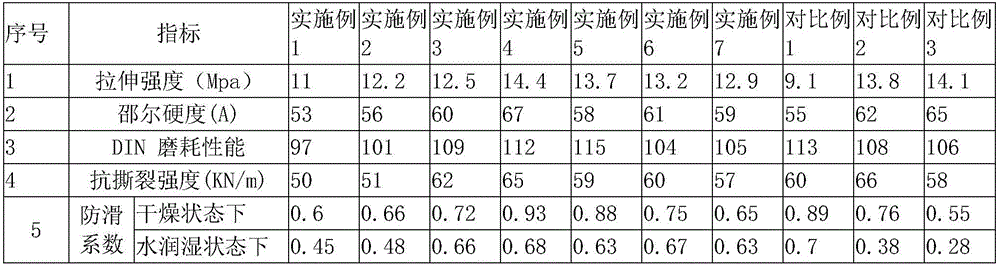

[0061] Test the tensile strength of the sole material made, Shore hardness (A), DIN abrasion resistance, tear strength (KN / m), and the anti-slip coefficient under both conditions of wet and dry, the data obtained are shown in Table 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com