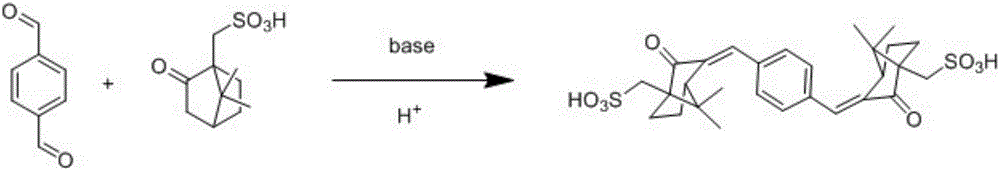

Preparation method of terephthalylidene dicamphor sulfonic acid sun-screening agent

A technology of xylylene biscamphorsulfonic acid and camphorsulfonic acid, which is applied in the fields of sulfonic acid preparation and organic chemistry, can solve the problems of difficult stirring, poor solubility, difficult filtration, etc., and achieves low cost and simple equipment , the effect of easy mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In a 1000ml four-necked round bottom flask, add 60g camphorsulfonic acid, 116ml mass content of 25% sodium methylate methanol solution and 310ml cyclohexane, nitrogen protection, stir at 75°C for 60min, and reclaim the low boiling point solvent with a water separator; then Add dropwise a methanol-cyclohexane solution containing 17.6g of terephthalaldehyde, wherein the volume ratio of methanol to cyclohexane is 1:6; keep warm at 70°C for 80min, and recover the low boiling point solvent; after the reaction is completed, add 280ml of water and wash with concentrated hydrochloric acid Adjust the pH to 2 and raise the temperature to 90°C, then separate the liquids and recover cyclohexane; add 250ml of ethanol to the water layer, cool it to -15°C, and then filter with suction to obtain a white solid, which is then vacuum-dried to obtain p-xylylene Dicamphorsulfonic acid sunscreen agent 42.7g, its mass content as determined by HPLC is 99.74%.

Embodiment 2

[0030] In a 1000ml four-necked round bottom flask, add 60g camphorsulfonic acid, 120ml mass content of 30% sodium methylate methanol solution and 460ml cyclohexane, nitrogen protection, react at 65°C for 120min, and reclaim the low boiling point solvent with a water separator; then Add dropwise a methanol-cyclohexane solution containing 17.4g of terephthalaldehyde, wherein the volume ratio of methanol to cyclohexane is 1:6; keep warm at 75°C for 30 minutes, and recover the low boiling point solvent; after the reaction is completed, add 410ml of water and wash with concentrated hydrochloric acid Adjust the pH to 1, and raise the temperature to 90°C, then separate the liquid and recover cyclohexane; add 300ml of acetone to the water layer, cool down to -10°C, and filter with suction to obtain a white solid terexylylene biscamphorsulfonic acid sunscreen 45.0g, its mass content determined by HPLC is 99.68%.

Embodiment 3

[0032] In a 1000ml four-necked round bottom flask, add 68g camphorsulfonic acid, 130ml mass content of 28% sodium methylate methanol solution and 350ml cyclohexane, nitrogen protection, react at 65°C for 20min, and reclaim the low boiling point solvent with a water separator; then Add dropwise methanol-cyclohexane solution containing 17.6g of terephthalaldehyde, the volume ratio of methanol to cyclohexane is 1:5; keep warm at 65°C for 100min, and recover the low boiling point solvent; after the reaction is completed, add 350ml of water and adjust with concentrated hydrochloric acid pH = 3, and heated up to 90°C, then separated and recovered cyclohexane; the water layer was directly cooled to 25°C at low temperature, and suction filtered to obtain 32 g of white solid terexylylene biscamphorsulfonic acid sunscreen, which was determined by HPLC The mass content is 99.89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com