Method for extracting chlorogenic acid

An extraction method, a technology of chlorogenic acid, applied in chemical instruments and methods, separation/purification of carboxylate, preparation of carboxylate, etc., can solve the problems of high production cost and low purity of the extract, and achieve simple extraction steps , The effect of easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

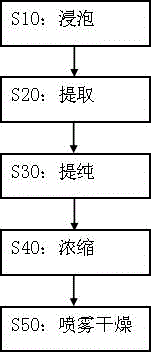

Image

Examples

Embodiment 1

[0023] After 20kg of green coffee beans were pulverized, 70% ethanol solution was added as an extractant, the mass ratio of extractant to green coffee beans was 6:1, after soaking for 1 hour, 500W microwave extraction was performed three times at a temperature of 55°C to obtain the primary extract.

[0024] The primary extract was added to simulated moving bed chromatography for separation. Wherein the adsorbent is SP207 macroporous resin, the desorbent is 50% ethanol solution, and its consumption is 3 times of the resin volume; the resin adsorption regeneration solvent is 95% ethanol solution; the elution rate is 1.5BV / h, and the temperature is 55 ℃, the pressure is 0.5MPa. Using an external heating single-effect decompression vacuum concentrator to separate the extractant from the separated extract to obtain a chlorogenic acid concentrate.

[0025] The chlorogenic acid concentrate is spray-dried, the air inlet temperature of the spray drying unit is 125°C, the air outlet te...

Embodiment 2

[0027] After 20kg of green coffee beans are crushed, add 65% ethyl acetate solution as an extractant, the mass ratio of extractant to green coffee beans is 7.5:1, after soaking for 0.5 hours, extract with 500W microwave three times at a temperature of 65°C to obtain the initial extraction liquid.

[0028] The primary extract was added to simulated moving bed chromatography for separation. Wherein the adsorbent is SP207 macroporous resin, the desorbent is 45% ethanol solution, and its consumption is 3 times of the resin volume; the resin adsorption regeneration solvent is 95% ethanol solution; the elution rate is 2.0BV / h, and the temperature is 55 ℃, the pressure is 0.5MPa. Using an external heating single-effect decompression vacuum concentrator to separate the extractant from the separated extract to obtain a chlorogenic acid concentrate.

[0029] The chlorogenic acid concentrated solution is spray-dried, the air inlet temperature of the spray drying unit is 120°C, the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com