Method for producing high-nitrogen sulfur-based water soluble compound fertilizer through slurry-spraying granulation

A spray granulation and compound fertilizer technology, which is applied in the direction of fertilization equipment, fertilizer form, fertilizer mixture, etc., can solve the problems of high insoluble matter, insufficient nitrogen content of sulfur-based compound fertilizer, and inapplicable flushing fertilization, etc., to achieve insoluble matter The effect of less, high nitrogen content, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

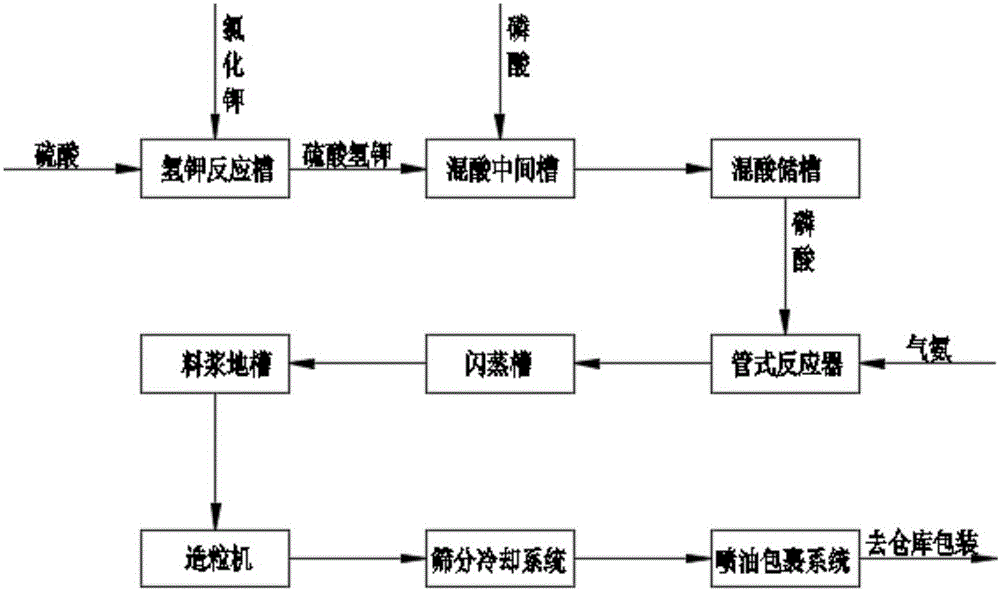

[0019] Embodiment 1 Existing spray granulation produces the method for sulfur-based compound fertilizer

[0020] Such as figure 1 As shown, first add sulfuric acid and potassium chloride to the potassium hydrogen reaction tank to react to generate potassium hydrogen sulfate, then add phosphoric acid to the potassium hydrogen sulfate in the middle tank of mixed acid and send it to the tubular reactor to feed ammonia gas for reaction. After the completion, the flash slurry is obtained by flashing through the flash tank, and then the flash slurry is granulated, and the compound fertilizer obtained from the granulation is screened and then enters the oil spray coating system to be coated to obtain the compound fertilizer.

[0021] The compound fertilizer produced according to the method contains more than 5 percent of insoluble matter, 11 to 12 percent of nitrogen, and 2 to 4 mm in particle size of the compound fertilizer, which cannot be used for flushing fertilization.

Embodiment 2

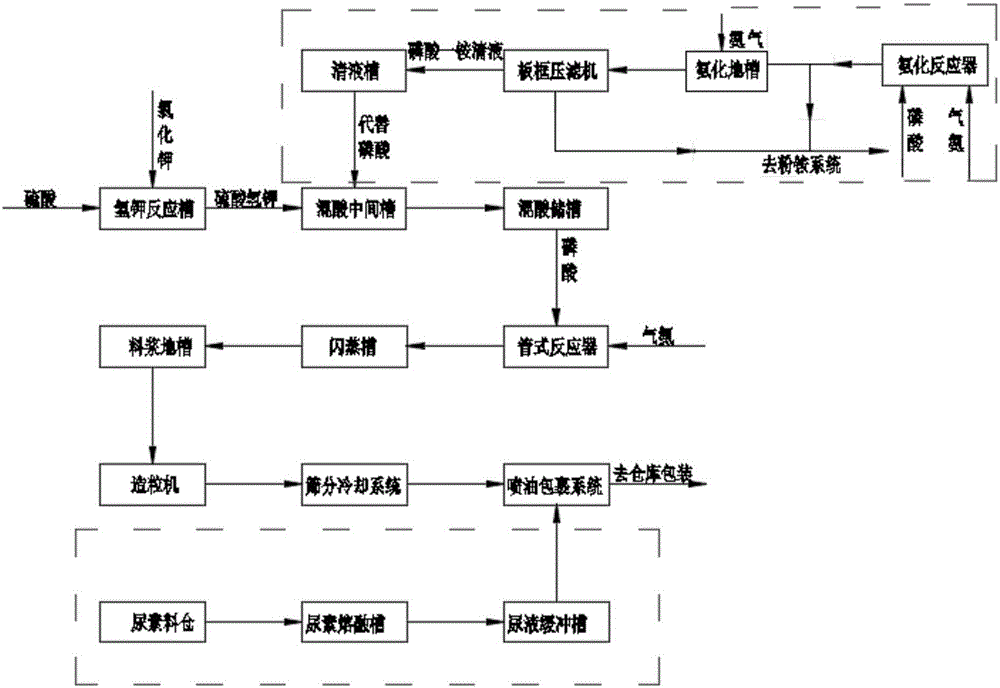

[0022] Embodiment 2 The method of spraying granulation of the present invention to produce high-nitrogen and sulfur-based compound fertilizer

[0023] Such as figure 2 As shown, the phosphoric acid added to the mixed acid intermediate tank is obtained in the following way:

[0024] Sulfuric acid and potassium chloride are added into the potassium hydrogen reaction tank to react to generate potassium hydrogen sulfate. Then phosphoric acid and ammonia are pre-neutralized in the ammoniation reactor to obtain a pre-neutralized slurry. The temperature of the pre-neutralized slurry is 75-80°C, the pH value is 3.5-4.0, and the density is 1.25-1.28mg / L. Adjust the pH value of one-third of the pre-neutralization slurry to 4.0-4.5, and then obtain the filter residue and filtrate through pressure filtration. The density of the filtrate is 1.20-1.23mg / L, of which P 2 o 5 The content is 19 to 20%. A large amount of insoluble matter in the pre-neutralized slurry has been filtered out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com