A Calculation Method of Surface Area Mix Ratio of Sand-free Concrete

A technology of sand-free concrete and calculation method, applied in the direction of ratio control, instrument, control/regulation system, etc., can solve problems such as endangering engineering safety, waste of cement, affecting water permeability and air permeability of sand-free concrete, etc. good representative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific embodiments.

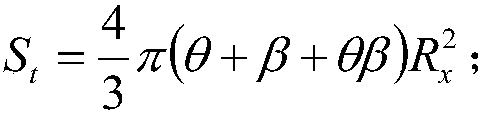

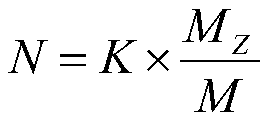

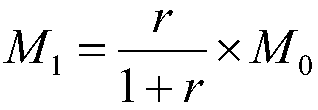

[0032] The present invention uses a series of algorithms to estimate the total surface area of the aggregate per unit volume, and then obtains the appropriate slurry thickness of the aggregate and the corresponding water-cement ratio through experiments; by calculating the product of the total surface area and the slurry thickness and multiplying it by the corresponding The adequacy coefficient of the total amount of cement slurry can be obtained, and then the specific amount of water and cement can be obtained.

[0033] A method for calculating the proportion of sand-free concrete surface area, comprising the following steps:

[0034] (1) The aggregate is regarded as an ellipsoid, and n samples are taken to measure the axis length ratios of the three orthogonal axes, and the average value is the three-axis ratio 1:θ:β of the aggregate model; for randomly selected bones ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com