BCNO (Boron-Carbon-Nitrogen-Oxygen) material, as well as preparation method and application thereof in fluorescent material

A technology of melamine and microspheres, applied in luminescent materials, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as poor controllability of morphology, and achieve simple and environmentally friendly methods, good particle size uniformity, and uniform particle size distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1 Preparation of melamine formaldehyde resin MF microspheres

[0053] MF-1 # preparation of

[0054] Add melamine and formaldehyde solution (concentration: 37%-40%) into water respectively, stir, heat at 60°C for 10 minutes to form a uniform and transparent solution, and then keep at 80°C for 10 minutes; wherein, the mass ratio of the materials Be melamine: formaldehyde solution: water=1.2:9.4:19.4. Put the obtained solution into a 100mL reaction kettle, heat at 180°C for 6h; after cooling down to room temperature, filter and wash with ethanol and water; dry in an oven at 70°C; obtain the precursor melamine-formaldehyde resin microspheres, denoted as MF -1 # . MF-1 # The particle size range is 4 μm to 6 μm.

[0055] MF-2 # preparation of

[0056] According to the method in the literature [Preparation and Characterization of Monodisperse Nickel Plated / Silver Melamine Formaldehyde Resin Microspheres, Journal of Nanjing University, 2014, 50(1):54-60]...

Embodiment 2

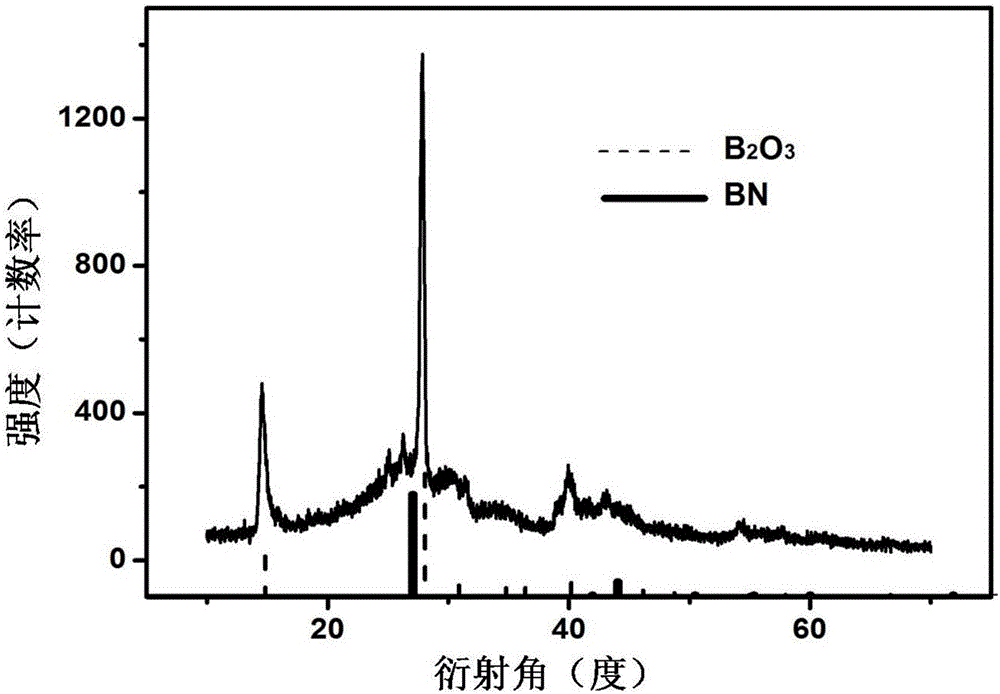

[0057] Example 2 Preparation of BCNO material samples

[0058] Dissolve boric acid in 100 ml of deionized water, and dissolve completely under heating and stirring at 80°C; then add 0.5 g of melamine-formaldehyde resin microspheres to the boric acid solution, and keep at 80°C until evaporated to dryness to obtain a white solid powder; the resulting white solid powder is in Sinter at a certain temperature for a period of minutes, and take it out immediately after the sintering is completed; finally, after grinding the taken out product, the BCNO material sample is obtained.

[0059] The relationship between the sample number and the type of melamine formaldehyde resin microspheres, the amount of boric acid, sintering temperature and sintering time is shown in Table 1.

[0060] Table 1

[0061]

Embodiment 3

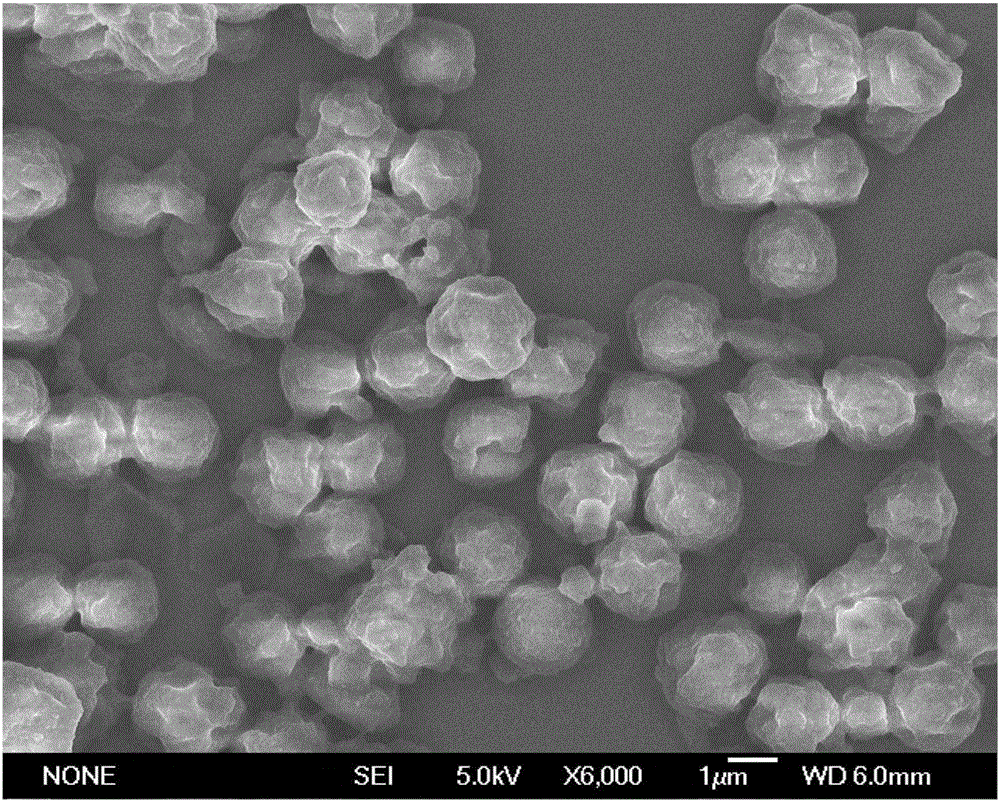

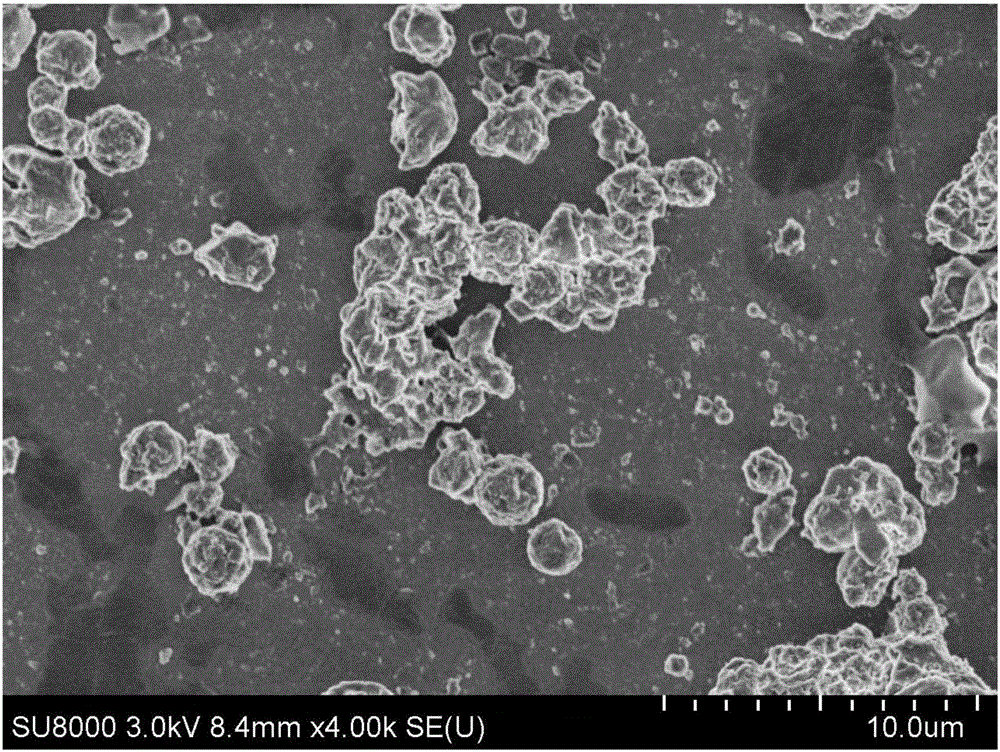

[0062] The particle size distribution characterization of embodiment 3 BCNO material sample

[0063] For sample 1 # ~Sample 7 # The average particle size and particle size distribution were measured, and the results are shown in Table 1. As can be seen from Table 1, sample 1 # ~Sample 7 # The standard deviation of the distribution is between 0.07 and 0.322, and the sample 1 whose sintering temperature is between 700 ° C and 800 ° C # , sample 4 # , sample 6 # and sample 7 # The standard deviation of BCNO is between 0.07 and 0.266, indicating that the particle size distribution of the BCNO material obtained by the preparation method provided by this application is narrow and the particle size is uniform; the particle size of the sample with the amount of boric acid being 0.155 and the sintering temperature between 700°C and 800°C Uniformity is better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap