Oil-electric hybrid rotor unmanned aerial vehicle multi-power source decoupling and vector control device and method

A rotor unmanned, vector control technology, applied in the direction of power units, motor vehicles, unmanned aircraft, etc. on aircraft, can solve the problems of slow flight speed, stall, low motor speed, etc., to improve flight speed and stability. effect of flight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

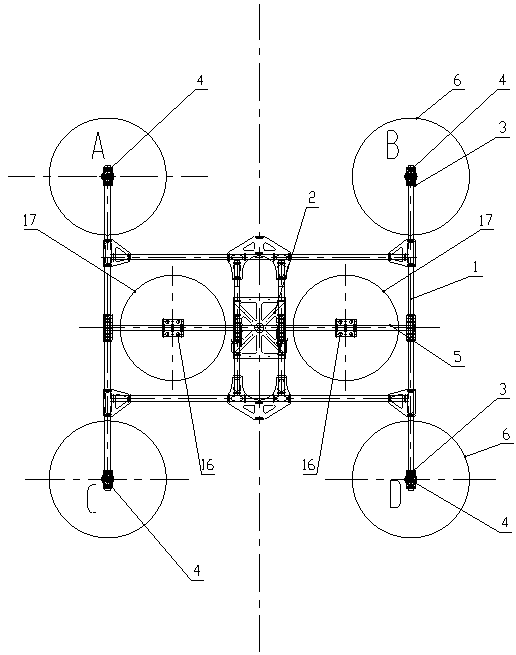

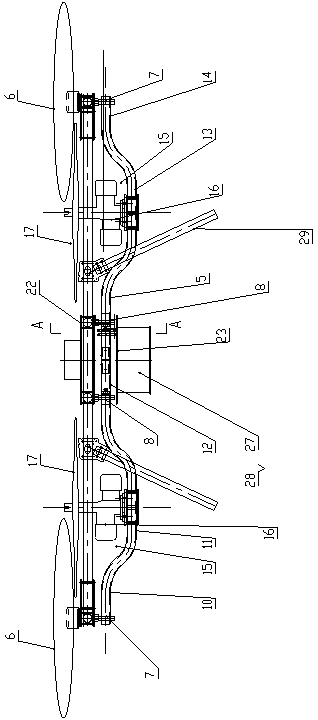

[0040] Such as figure 1 , 2 As shown in . The central platform 2 of the frame at the position, and the UAV frame 1 is provided with an even number of arms 3, figure 1 The embodiment in is a multi-rotor UAV with a four-axis "X" configuration. Four arms 3 are arranged on the frame 1 of the UAV. Each arm 3 is connected to a motor 4, and each motor 4 is connected to There are 6 motor propellers. Also be connected with landing support 29 on the UAV frame 1.

[0041] Four T-motor u11 motors are selected and equipped with 28-inch carbon fiber propellers. If the take-off weight is 47kg, the pulling force generated at 50% throttle is about 22kg.

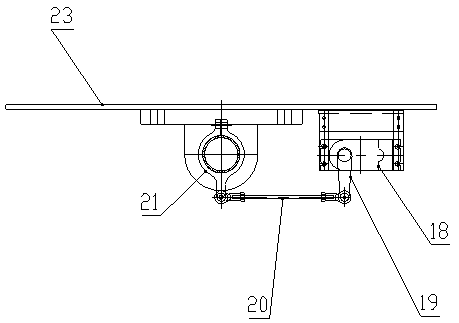

[0042] The rotor drone of the present invention also includes a gasoline power vector shaft 5, the left and right ends of the gasoline power vector shaft 5 are rotationally connected with the UAV frame 1, and the two ends of the gasoline power vector shaft 5 are connected to the UAV frame 1. An end bearing 7 is provided, and the middle p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com