High temperature superconducting magnetic suspension vehicle driven by permanent magnet linear synchronous motor without gear grooves

A permanent magnet synchronous linear, high-temperature superconducting technology, applied in the field of vehicles, can solve problems affecting the operating comfort of maglev vehicles, motor normal force and thrust fluctuations, suspension system stability disturbances, etc., to improve the overall suspension capacity, The effect of small disturbance and large vehicle payload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

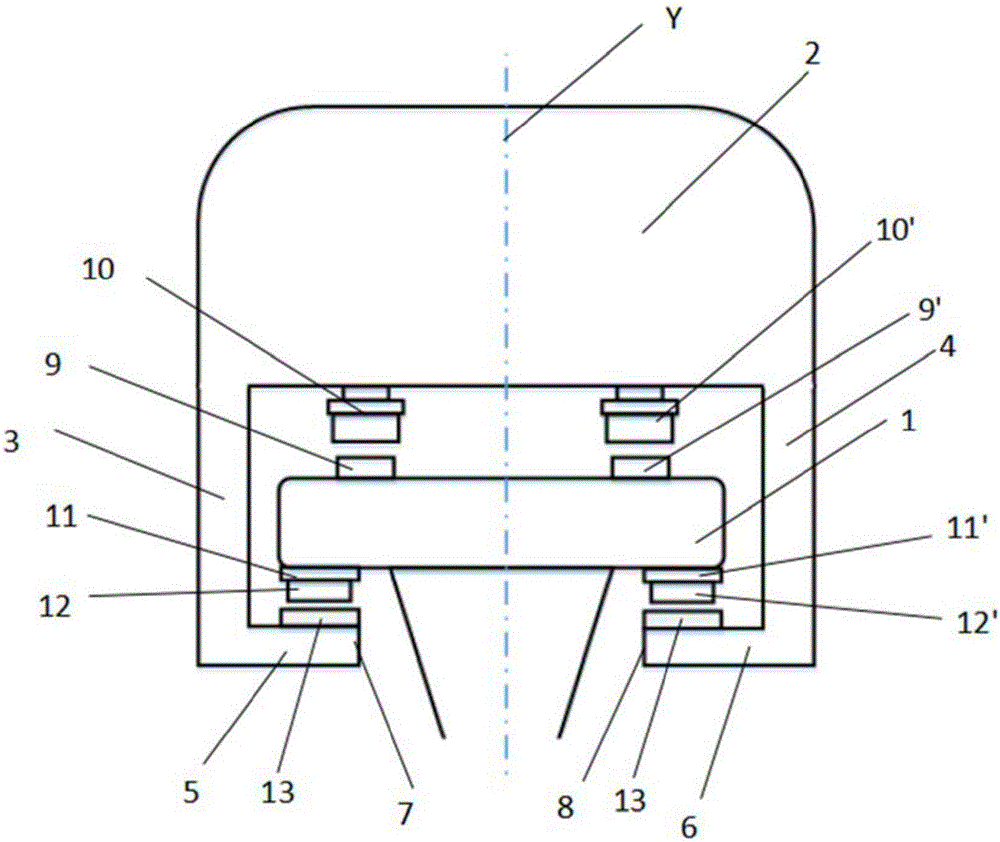

[0039] This embodiment provides a high-temperature superconducting magnetic levitation vehicle driven by a unilateral non-cogged permanent magnet synchronous linear motor, such as figure 2 As shown, it includes a car body, a high-temperature superconducting suspension system that suspends and guides the car body, and is connected with a track beam 1 for driving the car body, and is used to drive the car body along the The linear motor propulsion system for the movement of the track beam 1; the car body includes: a main body 2 with a vertical central axis Y; The first extension part 3 and the second extension part 4 are symmetrically arranged, and the bottom end of the first extension part 3 is formed with a first bending part 5; the bottom end of the second extension part 4 is formed with a second bend Bending portion 6; the free end 7 of the first bending portion 5 is opposite to the free end 8 of the second bending portion 6, and the two free ends 7 and 8 are arranged symme...

Embodiment 2

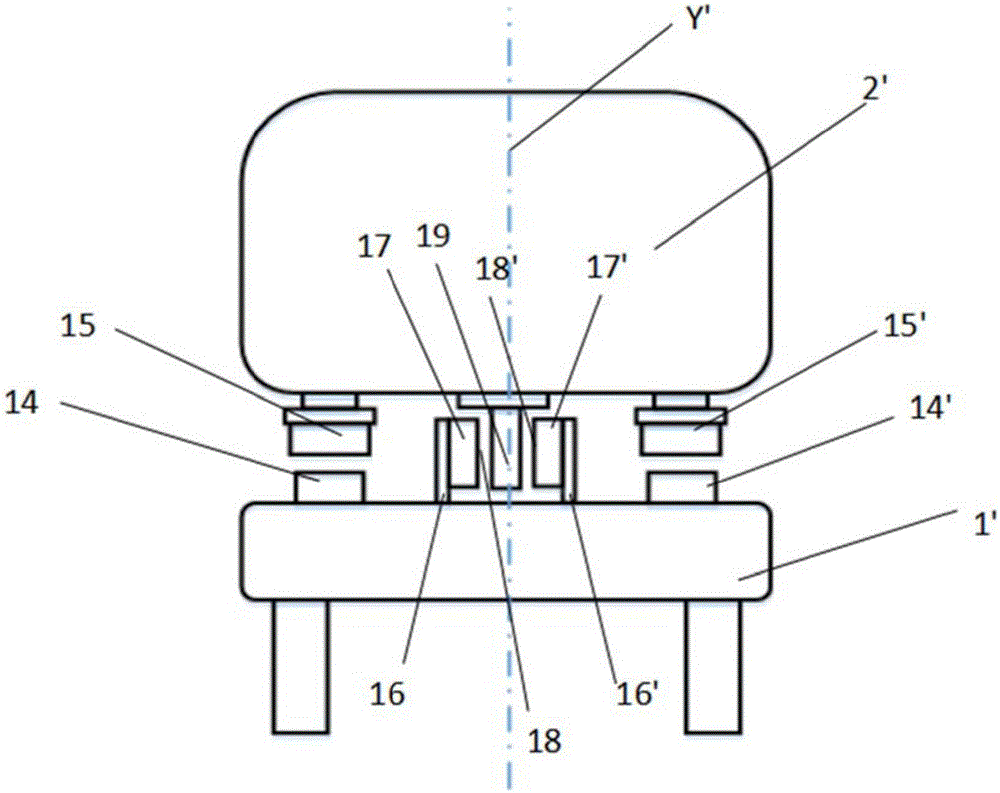

[0049] This embodiment provides a high-temperature superconducting magnetic levitation vehicle driven by a double-sided non-cogging permanent magnet synchronous linear motor, such as image 3 As shown, the high-temperature superconducting maglev vehicle driven by the double-sided non-cogged permanent magnet synchronous linear motor includes a vehicle body 2' having a vertical central axis Y', making the vehicle body 2' suspend and supporting the vehicle body 2 A high-temperature superconducting suspension system for guiding and a linear motor propulsion system connected to the track beam 1' for the vehicle body 2' to drive the vehicle body 2' to move along the track beam 1', Wherein, the linear motor propulsion system is arranged in the upper middle of the track beam 1'.

[0050] Specifically, the high-temperature superconducting suspension system includes permanent magnet tracks 14 and 14 that are symmetrically arranged on both sides above the track beam 1' along the vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com