High-efficiency ultraviolet-resistant automobile sun visor lens and lens molding process

A car sun visor and anti-ultraviolet technology, which is applied in the direction of vehicle parts, synthetic resin layered products, transportation and packaging, etc., can solve the problem of visual fatigue for drivers who do not have anti-corrosion, anti-radiation, anti-ultraviolet, anti-scratch, etc. , can not guarantee the clarity of vision and other issues, to achieve the effect of excellent transparency, eye protection, good explosion-proof function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

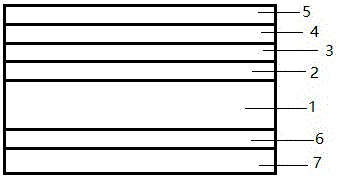

[0035] see figure 1 , a high-efficiency anti-ultraviolet automotive sun visor lens, comprising a PC resin layer 1, the front of the PC resin layer 1 is provided with a hardened layer 2; the front of the hardened layer 2 is provided with an antibacterial layer 3; the antibacterial layer 3 The front is provided with an anti-ultraviolet layer 4; the front of the anti-ultraviolet layer 4 is provided with a colored layer 5; the back of the PC resin layer 1 is provided with an anti-corrosion layer 6; the back of the anti-corrosion layer 6 is provided with a waterproof and oil-proof layer 7; Resin layer 1 comprises the following weight ratio raw materials:

[0036] PC resin: 65 parts, polypropylene glycol: 20 parts, styrene block copolymer: 8 parts, dibutyl phthalate: 7.5 parts, methacryloxysilane: 3 parts, maleic anhydride: 3 parts , barium stearate: 2 parts, nano silicon dioxide: 1.2 parts, stabilizer: 0.8 parts, nucleating agent: 0.25 parts, initiator: 0.6 parts, antioxidant: 0.1...

Embodiment 2

[0056] see figure 1 , a high-efficiency anti-ultraviolet automotive sun visor lens, comprising a PC resin layer 1, the front of the PC resin layer 1 is provided with a hardened layer 2; the front of the hardened layer 2 is provided with an antibacterial layer 3; the antibacterial layer 3 The front is provided with an anti-ultraviolet layer 4; the front of the anti-ultraviolet layer 4 is provided with a colored layer 5; the back of the PC resin layer 1 is provided with an anti-corrosion layer 6; the back of the anti-corrosion layer 6 is provided with a waterproof and oil-proof layer 7; Resin layer 1 comprises the following weight ratio raw materials:

[0057] PC resin: 70 parts, polypropylene glycol: 15 parts, styrene block copolymer: 12 parts, dibutyl phthalate: 5 parts, methacryloxysilane: 2.54 parts, maleic anhydride: 5 parts , barium stearate: 1 part, nano silicon dioxide: 1.95 parts, stabilizer: 0.5 part, nucleating agent: 0.13 part, initiator: 0.9 part, antioxidant: 0.5 ...

Embodiment 3

[0077] see figure 1 , a high-efficiency anti-ultraviolet automotive sun visor lens, comprising a PC resin layer 1, the front of the PC resin layer 1 is provided with a hardened layer 2; the front of the hardened layer 2 is provided with an antibacterial layer 3; the antibacterial layer 3 The front is provided with an anti-ultraviolet layer 4; the front of the anti-ultraviolet layer 4 is provided with a colored layer 5; the back of the PC resin layer 1 is provided with an anti-corrosion layer 6; the back of the anti-corrosion layer 6 is provided with a waterproof and oil-proof layer 7; Resin layer 1 comprises the following weight ratio raw materials:

[0078] PC resin: 60 parts, polypropylene glycol: 25 parts, styrene block copolymer: 10 parts, dibutyl phthalate: 10 parts, methacryloxysilane: 2 parts, maleic anhydride: 4 parts , barium stearate: 3 parts, nano silicon dioxide: 1.5 parts, stabilizer: 0.2 parts, nucleating agent: 0.5 parts, initiator: 0.2 parts, antioxidant: 0.25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com