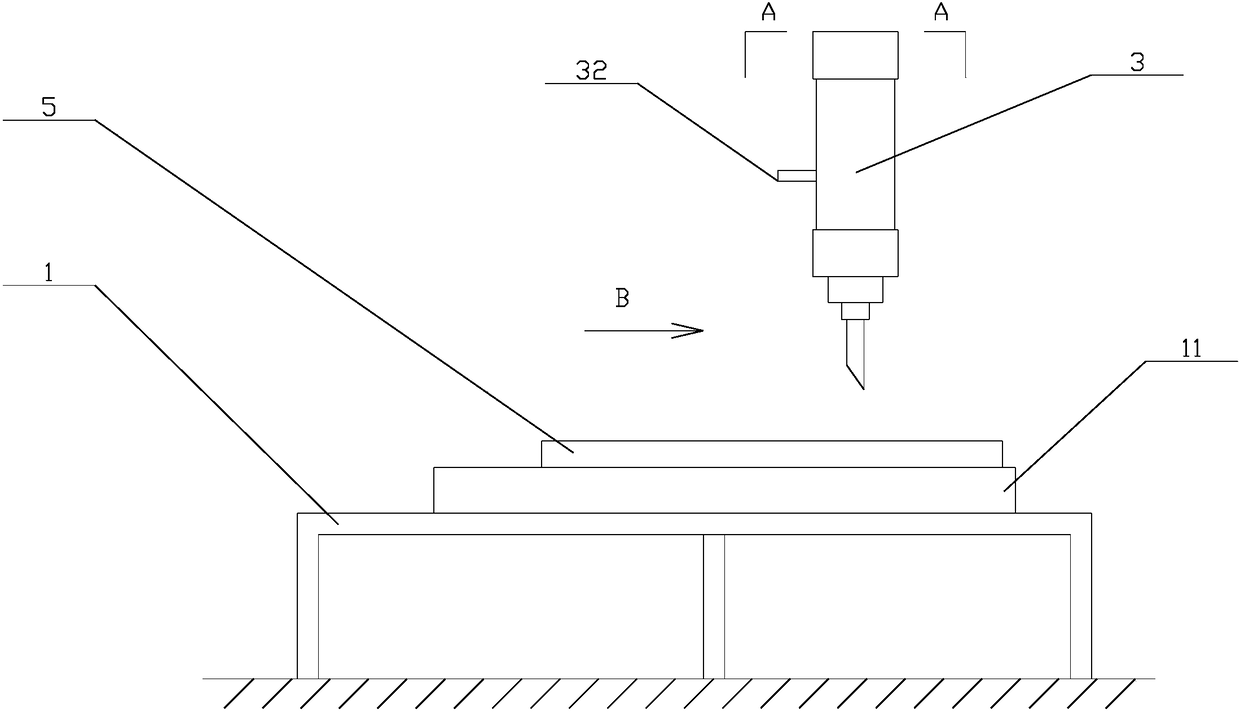

A New Needle Plate Knocking Device

A needle plate, a new type of technology, applied in the direction of needle looms, textiles, papermaking, non-woven fabrics, etc., can solve the problems of unresolved steel needles, high labor intensity, and low efficiency, and achieve simple structure, low labor intensity, and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

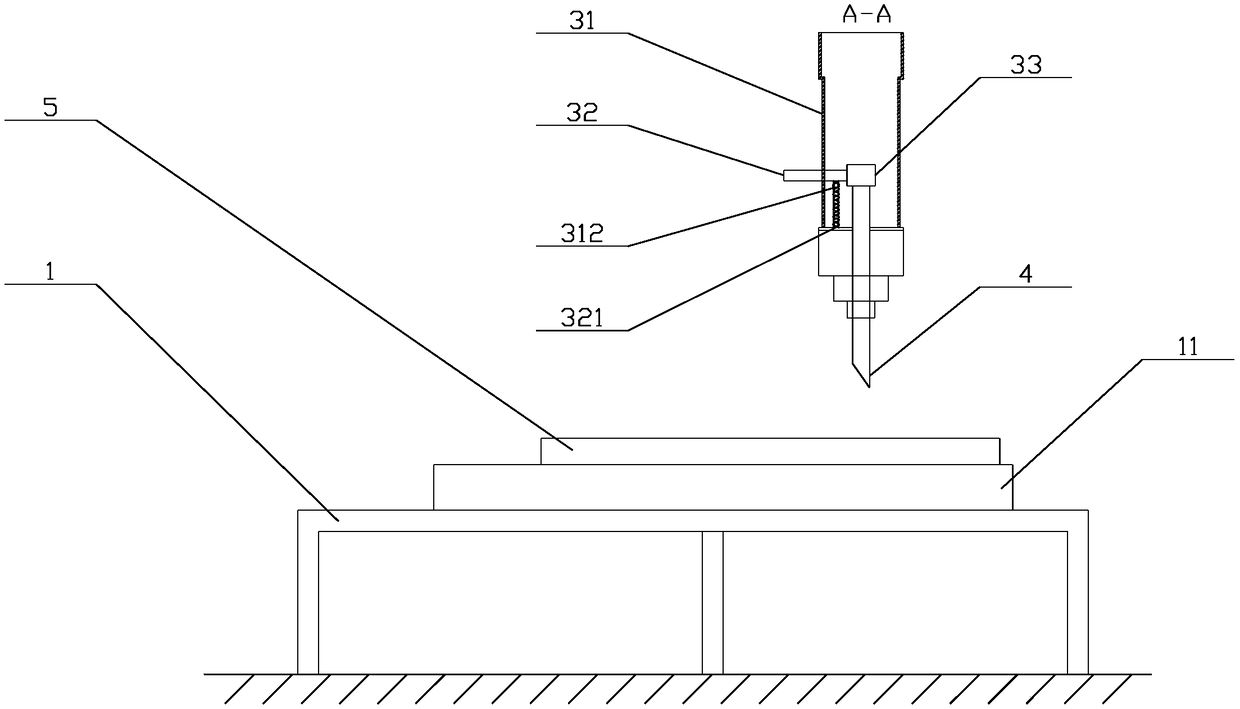

[0033] The action mechanism 3 includes a counterweight 33 arranged in the housing 31, the counterweight 33 is arranged on the top of the thimble 4, and the handle 32 is arranged on the counterweight 33; The part of the handle 32 in the housing 31 is provided with a spring fixing platform 321, and the position corresponding to the spring fixing platform on the inner wall of the housing 31 is provided with a spring fixing bracket 312, and between the spring fixing platform 321 and the spring fixing bracket 312, a Compression spring.

[0034] Utilize the reset force of the compression spring to keep the thimble away from the needle plate when not in use, which is convenient for the staff to locate. When in use, directly pull the handle to make the thimble move downward. After hitting the steel needle, let go, and the force of the compression spring resets Drive the thimble to reset automatically, improve labor efficiency and reduce labor intensity.

Embodiment 2

[0036] The action mechanism 3 includes an eccentric wheel 35 arranged in the housing 31, the thimble 4 is movably connected to the front of the eccentric wheel 35, and the reverse side of the eccentric wheel 35 is provided with a cam 351 for hitting, and the eccentric Wheel 35 is fixed in the described casing by rotating shaft 352; Also be provided with eccentric wheel striking device 36 in described casing 31, described eccentric wheel striking device 36 and the bottom of described casing 31 are provided with reset spring 37, so The eccentric beating device 36 is placed below the cam 351 . The kinetic energy released by the spring drives the eccentric wheel hitting device to hit the eccentric wheel, prompting the eccentric wheel to rotate, thereby driving the thimble to move downward, and completing the knocking action. The structure is simple and easy to operate, and the striking force is large, which improves the production efficiency. A track 38 is provided on the inner w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com