Grinding flow-guiding device suitable for grinding high-injection-pressure injection nozzle needle valve and grinding method

A diversion device and injection pressure technology, which is applied in the direction of abrasive material feeding device, abrasive material, metal processing equipment, etc., can solve the problems such as uncontrollable rounded corner shape of nozzle hole entrance, high processing pressure time, extrusion deformation of nozzle hole, etc. , to achieve the effect of prolonging the grinding time, prolonging the service life and reducing the flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

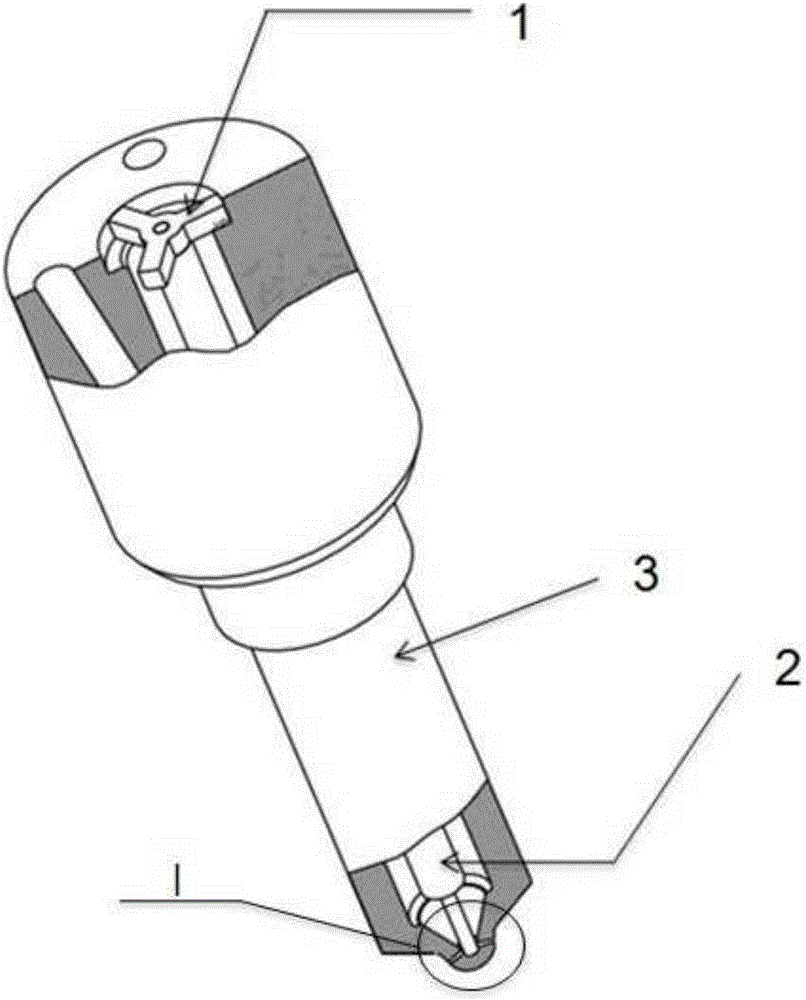

[0024] like image 3 , 4 Shown is a grinding guide device suitable for grinding the needle valve body of a high injection pressure fuel injection nozzle, including a positioning pin 1 and a guide rod 2 connected with the positioning pin 1; the positioning pin 1 is arranged on the needle valve of the fuel injection nozzle The movement of the guide rod 2 is restricted in the cavity of the body 3, and the head of the guide rod 2 is located at the entrance of the spray hole of the needle valve body 3 of the fuel injector, covering the lower half of the fillet of the spray hole entrance. The guide rod 2 is stepped, and the diameter of the head is smaller than the diameter of the tail. The head of the guide rod 2 is a plane, which is compatible with the size of the head of the needle valve body 3 of the fuel injector. The positioning pin 1 is a trident structure, and its diameter is adapted to the diameter of the cavity at the tail of the needle valve body 3 of the fuel injector. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com