A laser welding device for cladding welding of fuel rods with large length-to-diameter ratio

A large length-to-diameter ratio laser welding technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of large welding stress, welding seam oxidation, welding thermal cracks, etc., and achieve strong dimensional adaptability and overcome The effect of high reflectivity, high welding efficiency and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail below in conjunction with accompanying drawing:

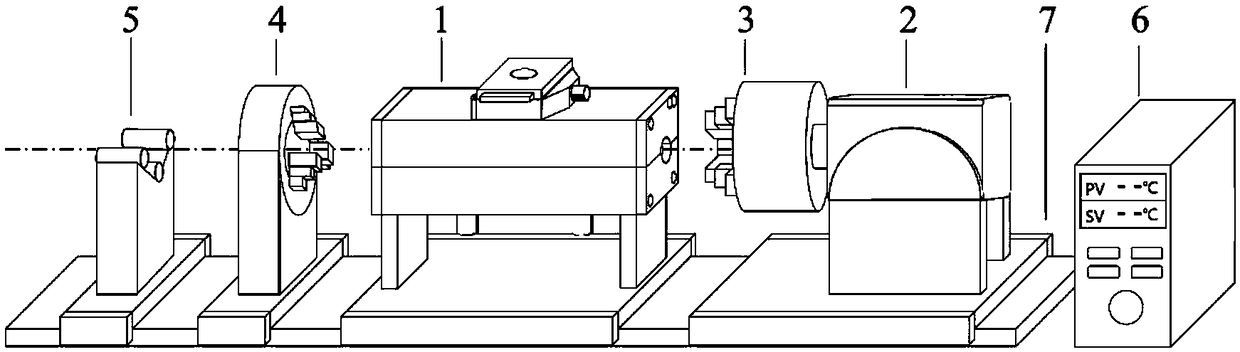

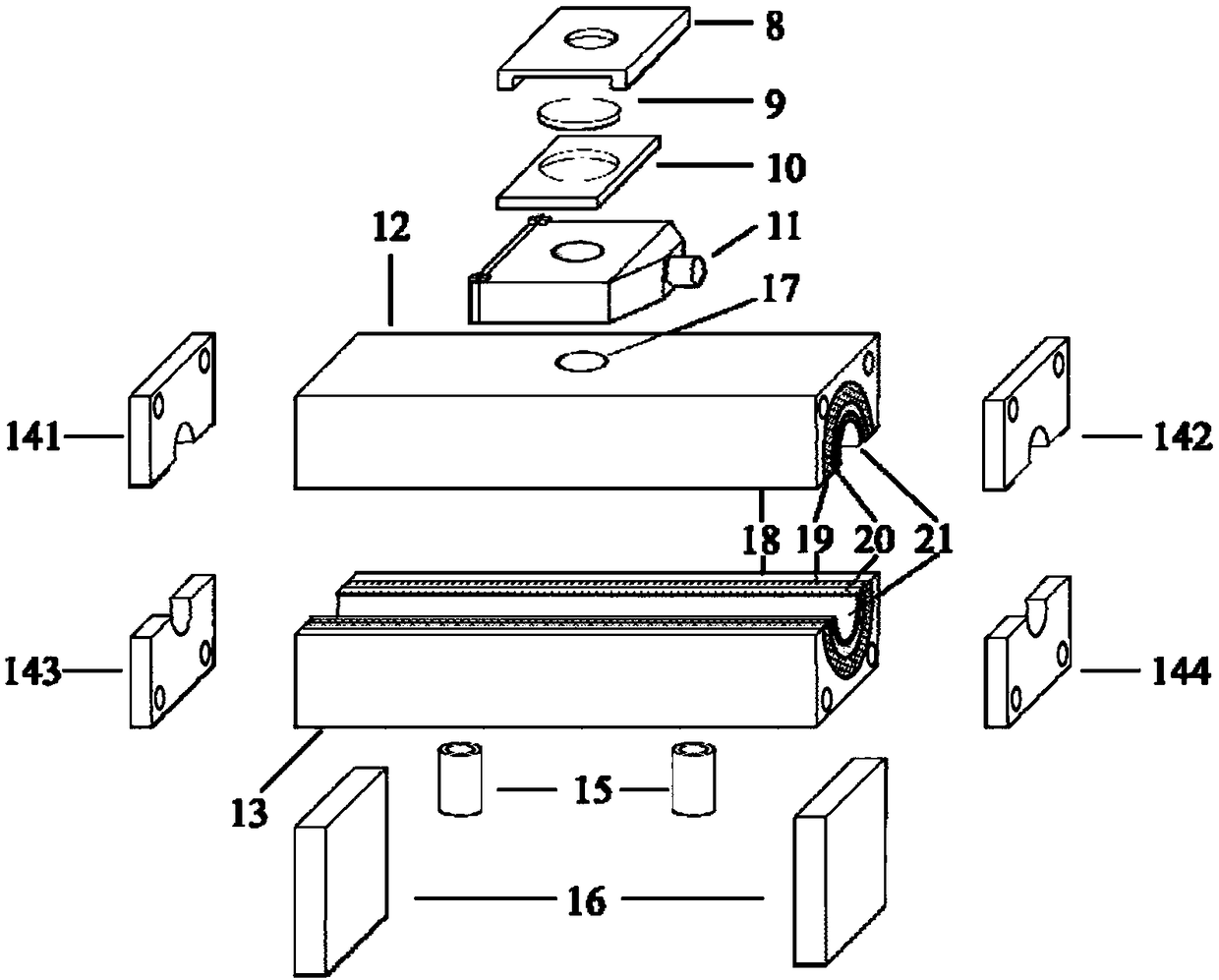

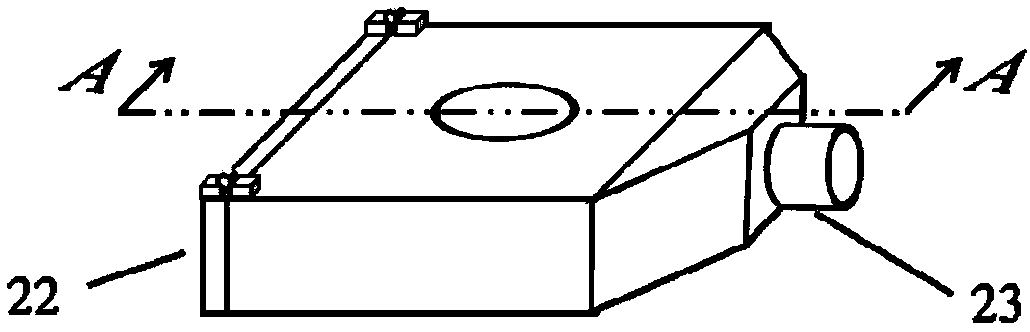

[0029] refer to Figure 1 to Figure 5, the laser welding device for cladding welding of fuel rods with large length-to-diameter ratio according to the present invention includes a laser welding head, a servo motor 2, an active three-jaw chuck 3, a gas shield 1, and a driven three-jaw chuck 4 And a number of support rollers 5, the gas protection cover 1 includes a protective cover upper part 12, a protective cover lower part 13, a protective gas input pipeline 15, a protective lens bracket 10 and a protective lens 9; a servo motor 2, three active claws The chuck 3, the gas protection sleeve 1, the driven three-jaw chuck 4, and the support rollers 5 are distributed sequentially from right to left. The upper part of the part 13 is provided with a second groove along the axial direction, and the upper half part 12 of the protective cover is buckled with the lower half par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com