Automatic tube sheet welder positioning device

A technology of automatic welding machine and positioning device, which is applied in the direction of auxiliary devices, welding equipment, welding equipment, etc., and can solve the problems that the mandrel is not easy to pull out, the mandrel cannot be pulled out, and the normal progress of the automatic welding of the tube sheet is affected. Achieve mobile and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

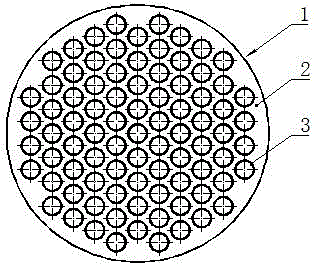

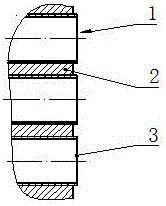

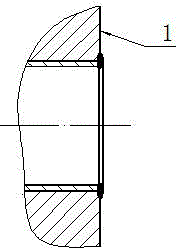

[0031] The end structure of the coiled tube heat exchanger 1 is as follows: figure 1 As shown, the heat exchange tubes 3 are arranged equidistantly through the tube sheet 2 according to a certain rule, and then the ends of the heat exchange tubes are scraped flat by 1-2 mm from the end surface of the tube sheet, as shown in figure 2 shown. After the end of the heat exchange tube is scraped flat, it can be welded. After welding, the weld pattern is as follows: image 3 shown.

[0032] When using the positioning device 4 of the tube-sheet automatic welding machine of the present invention for welding, it is necessary to first insert the conical positioning mandrel into the tube hole, and the welding nozzle moves in a circle around the heat exchange tube to complete the welding. After one heat exchange tube is welded, the positioning mandrel needs to be pulled out from the tube hole, and the head of the automatic welding machine is moved to weld the next heat exchange tube.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com