Shock absorber rolling and sealing method

A shock absorber and rolling technology, which is applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve the problems of material thinning, shock absorber seal damage and oil leakage, etc., to achieve good fit, Improve structural strength and smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

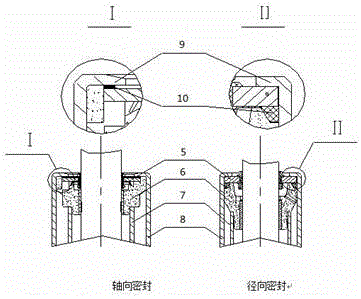

[0024] After axial flanging and sealing, the flanging metal presses the guide seat 6 tightly, so that a certain axial compressive stress remains in the axial direction of the working cylinder 7; the sealing flanging metal becomes thicker, and at the same time, the flanging mouth is bent to constrain the static seal Extrusion of the rubber 10, the mouth of the hemming metal is pressed tightly on the static sealing rubber 10 on the edge of the oil seal 5, and the static sealing rubber 10 will not tear; the axial rolling hemming sealing process achieves the thickening of the hemming metal The purpose of extruding the static sealing rubber 10 is to improve strength and bending forming restraint. The rolling wheel 4 is simple in structure and convenient to manufacture, and can be popularized and applied in the production of shock absorbers. The appearance of the new rolled hemming sealing part is smooth and clean, and it fits well with the guide seat 6 and the oil seal 5, fully m...

Embodiment 2

[0026] Embodiment 2, optimize design on the basis of embodiment 1, as Figure 4 , Figure 5 , Image 6 and Figure 7 As shown in , the radial sealing shock absorber is rolled and folded to become thicker, and the inclined sealing rolling wheel 4 rolls and bends the metal at the edge of the shock absorber 2 until the 5 corners of the oil seal of the shock absorber 2 are sealed. The part is pressed tightly against the guide seat 6; after a predetermined time, the rolling wheel 4 is gradually turned to the level, and the bent metal is radially squeezed by the arc surface of the retracting rolling wheel 4 to bend; the shock absorber 2 The hydraulic cylinder of the equipment continues to be sent vertically upward with a certain pressure. The conical surface of the rolling wheel 4 and the arc surface tangent to the conical surface and the end surface of the steel plate of the oil seal 5 enclose a cavity for bending metal after being turned over. The cylindrical surface of the pre...

Embodiment 3

[0028]Embodiment 3, optimize design on the basis of embodiment 1 or embodiment 2, the angle that rolling wheel 4 is inclined to set in described rolling flanging process is 45 °; Side positioning device is centering jig, fixed A positioning wheel is arranged on the center fixture. The rolling of the rolling wheel 4 at a specific angle is beneficial to forming the structure of the shock absorber after sealing, and the quality becomes thicker after sealing. The centering jig equipped with positioning wheels is used for centering and clamping the shock absorber, fully ensuring its positioning accuracy and sealing quality in rolling sealing, and improving the yield rate of finished products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com