Electromagnetic ultrasonic lamb wave transducer based on magnetostrictive mechanism

An electromagnetic ultrasonic and transducer technology, which is applied in the direction of vibrating fluid, etc., can solve the problems of accidental injury of operators, violent collision between transducer and plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

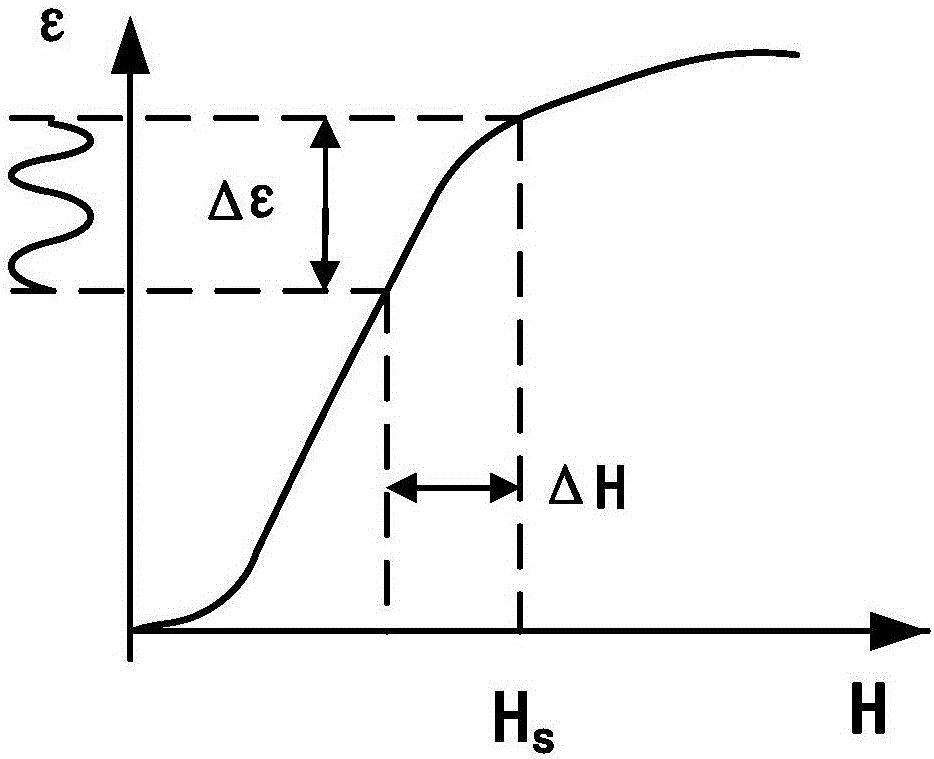

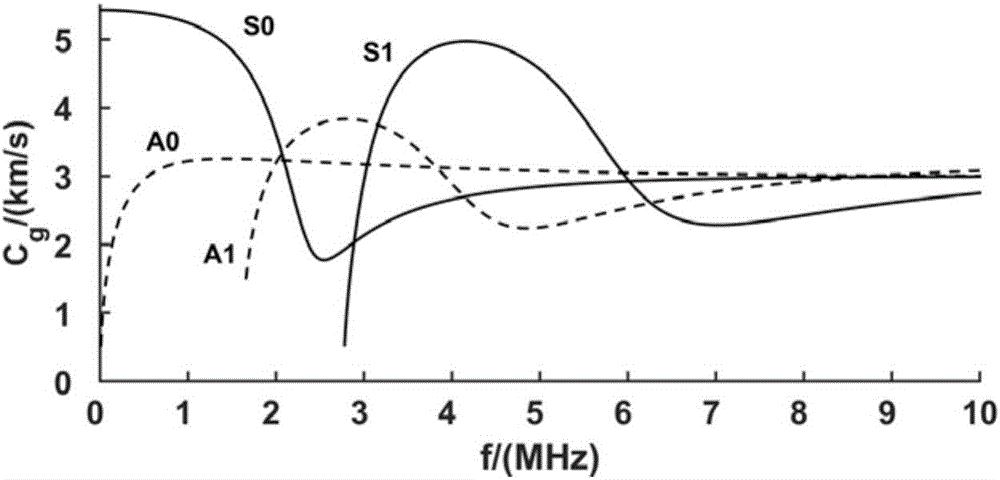

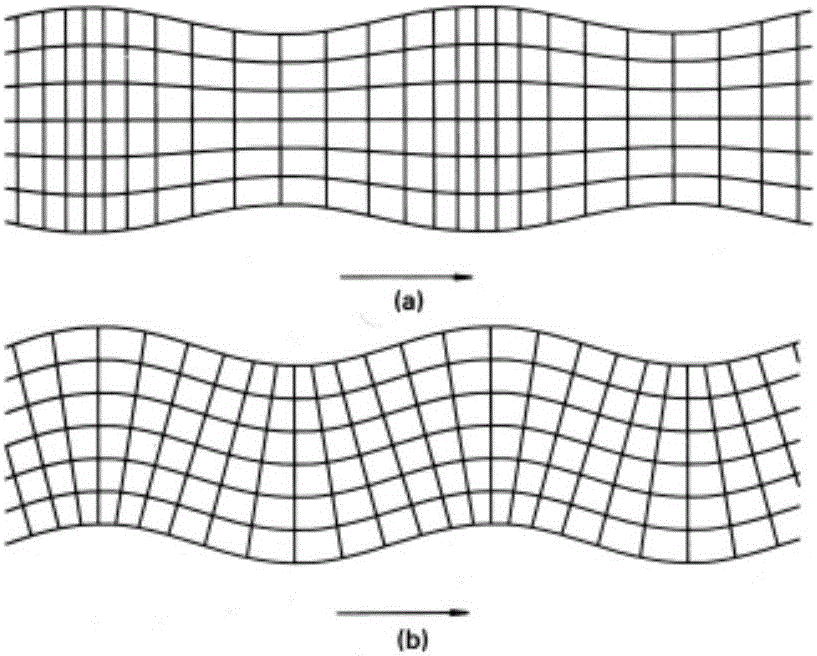

[0020] The magnetostrictive transducer is designed as Figure 4 with Figure 5 shown. Figure 4 For the coil winding method, the copper enameled wire with a diameter of 0.03mm to 5mm is selected for linear winding on a cylindrical plastic 3D printed plastic model. The diameter of the 3D printed model ranges from 10mm to 100mm, and the height ranges from 3mm to 50mm. The number of coil winding turns is 3 to 80 laps. The position relationship among coil, magnet and ferromagnetic plate is as follows: Figure 5 Shown: The magnet is magnetized in the horizontal direction and placed directly above the 3D printing model to provide a horizontal static bias magnetic field for the ferromagnetic sheet. The product of the excitation pulse current frequency and the thickness of the ferromagnetic sheet is less than 1.5MHz·mm to ensure that only S 0 and A 0 Lambo. The energy conversion process is carried out between the coil and the ferromagnetic plate to be tested, and the coupling sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com