The synthetic method of 3-hydroxy propionaldehyde

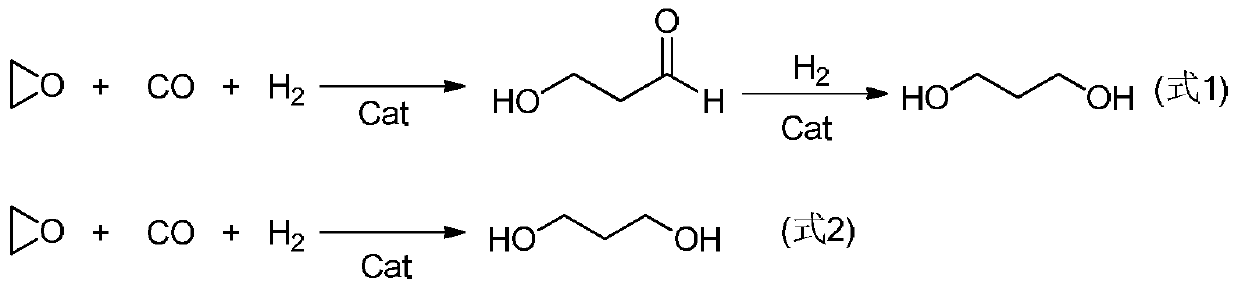

A technology of hydroxypropionaldehyde and its synthesis method, which is applied in chemical instruments and methods, preparation of heterocyclic compounds, organic compound/hydride/coordination complex catalyst, etc., can solve the problems of low yield of 3-hydroxypropionaldehyde, etc. Achieve strong electron donating ability and increase yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

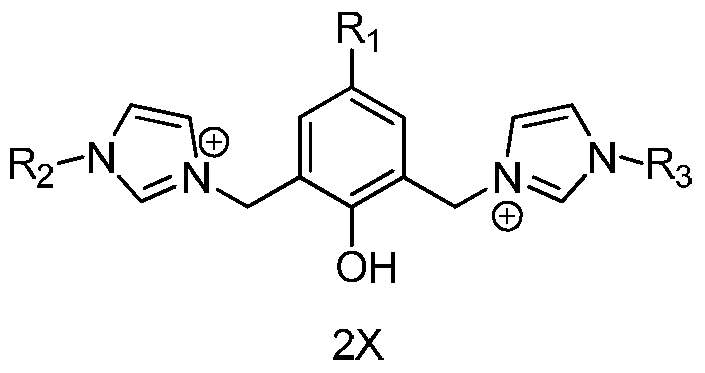

Method used

Image

Examples

Embodiment 1

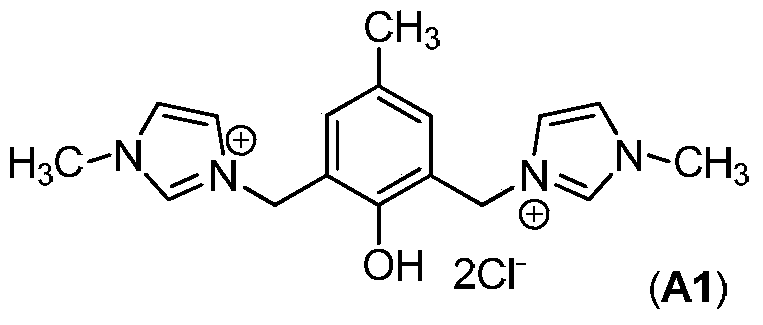

[0035] Add 2050mg (10mmol) 2,6-dichloromethyl-p-cresol, 3280mg (40mmol) 1-methylimidazole, 40mL 1,4-dioxane into a 100mL reaction tube, and replace the air in the reaction tube with nitrogen three times. Under nitrogen atmosphere, react at 100°C for 24 hours. After the reaction was completed, the resulting precipitate was filtered, washed with 1,4-dioxane and diethyl ether, and vacuum-dried to obtain 2285 mg of light yellow solid, which was the N-heterocyclic carbene ligand precursor A1.

[0036]

[0037] Take 1 mmol of N-heterocyclic carbene ligand precursor A1, 1 mmol of cobalt carbonate, and 30 mL of methyl tert-butyl ether, and add them into a 100 mL reaction kettle. High-purity nitrogen and syngas (V H2 / V CO =1 / 1) replace the gas in the kettle three times, heat to 65° C., and stir for 4 hours. Add the oxirane of 50mmol; Add synthesis gas (V H2 / V CO =2 / 1), make the system pressure 12MPa; react at 100°C for 3 hours. After fully cooling the reactor body to 0°C, th...

Embodiment 2

[0039] Add 2940mg (10mmol) 2,6-dibromomethyl-p-cresol, 3280mg (40mmol) 1-methylimidazole, 40mL 1,4-dioxane into a 100mL reaction tube, replace the air in the reaction tube with nitrogen three times, and Under nitrogen atmosphere, react at 100° C. for 20 hours. After the reaction was completed, the resulting precipitate was filtered, washed with 1,4-dioxane and diethyl ether, and vacuum-dried to obtain 2980 mg of light yellow solid, which was the N-heterocyclic carbene ligand precursor A2.

[0040]

[0041] Take 1 mmol of N-heterocyclic carbene ligand precursor A2, 1 mmol of cobalt carbonate, and 30 mL of methyl tert-butyl ether, and add them into a 100 mL reaction kettle. High-purity nitrogen and syngas (V H2 / V CO =1 / 1) replace the gas in the kettle three times, heat to 65° C., and stir for 4 hours. Add the oxirane of 50mmol; Add synthesis gas (V H2 / V CO =2 / 1), make the system pressure 12MPa; react at 100°C for 3 hours. After fully cooling the reactor body to 0°C, t...

Embodiment 3

[0043] Add 3880mg (10mmol) 2,6-diiodomethyl-p-cresol, 3280mg (40mmol) 1-methylimidazole, 50mL 1,4-dioxane into a 100mL reaction tube, and replace the air in the reaction tube with nitrogen three times. Under nitrogen atmosphere, react at 100°C for 24 hours. After the reaction was completed, the resulting precipitate was filtered, washed with 1,4-dioxane and diethyl ether, and vacuum-dried to obtain 3870 mg of light yellow solid, which was the N-heterocyclic carbene ligand precursor A3.

[0044]

[0045] Take 1 mmol of N-heterocyclic carbene ligand precursor A3, 1 mmol of cobalt carbonate, and 30 mL of methyl tert-butyl ether, and add them into a 100 mL reaction kettle. High-purity nitrogen and syngas (V H2 / V CO =1 / 1) replace the gas in the kettle three times, heat to 65° C., and stir for 4 hours. Add the oxirane of 50mmol; Add synthesis gas (V H2 / V CO =2 / 1), make the system pressure 12MPa; react at 100°C for 3 hours. After fully cooling the reactor body to 0°C, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com