Entire-column preparation method of nano-particle stabled Pickering emulsion based packing

A nanoparticle and monolithic column technology, applied in the fields of analysis and detection and micro-nano, can solve the problems of different hydrophilicity and hydrophobicity, and cannot separate and enrich molecules with different hydrophilicity and hydrophobicity at the same time, so as to achieve rich preparation methods, good biocompatibility, The effect of widening the variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

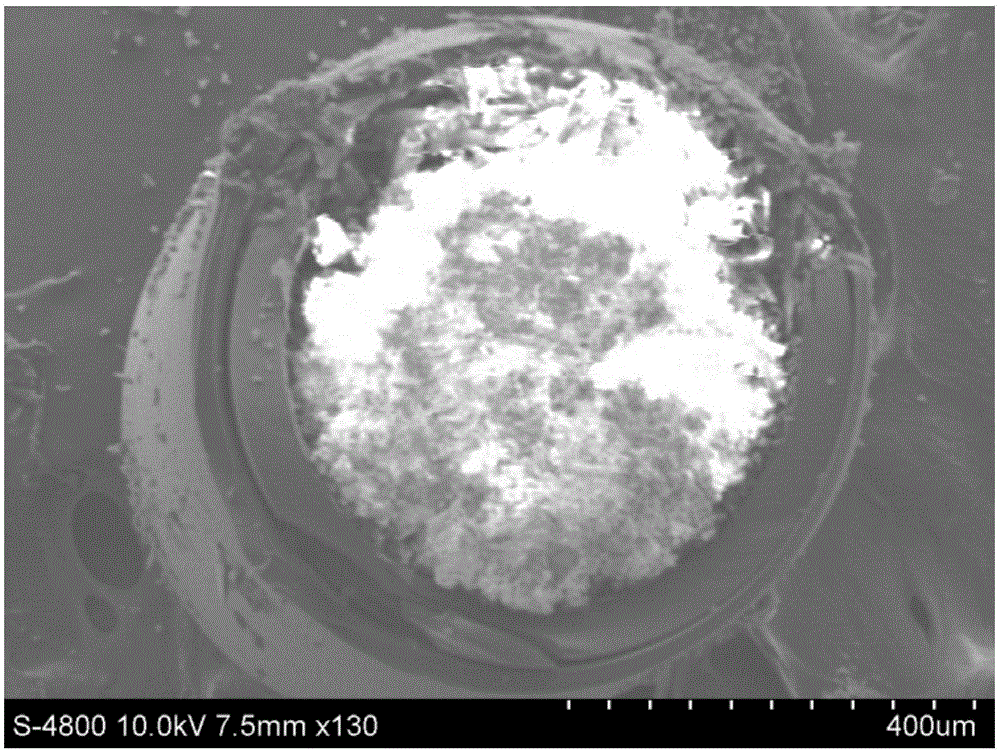

[0035] Embodiment 1: This embodiment is a method for preparing a monolithic column based on nanoparticle-stabilized Pickering emulsion as a filler. The method is specifically completed according to the following steps:

[0036] 1. Preparation of nanoparticles stabilized Pickering emulsion:

[0037] Mix the nanomaterials with the oil phase, then ultrasonically disperse for 10 to 60 minutes, add the water phase, and then vortex and mix for 1 to 10 minutes to obtain a nanoparticle-stabilized Pickering emulsion;

[0038] The oil phase described in step 1 is a mixture of solvent and silane, and the volume ratio of silane to solvent in the mixture of solvent and silane is (5 μL-30 μL): 1 mL;

[0039] The water phase described in step 1 is a mixed solution of distilled water and polyelectrolyte; the volume ratio of polyelectrolyte to distilled water in the water phase is (2μL-8μL): 1mL;

[0040] The volume ratio of the mass of the nanomaterial described in step 1 to the oil phase is...

specific Embodiment approach 2

[0059] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the power of the ultrasonic dispersion described in Step 1 is 30W-80W. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0060] Embodiment 3: The difference between this embodiment and Embodiment 1 or Embodiment 2 is that the rotation speed of the vortex mixing described in step 1 is 500r / min-3000r / min. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com