Clarification tank stirring and mud-scraping machine

A mud scraper and clarifier technology, which is applied in the field of construction machinery, can solve the problems of delayed clarifier mixing and scraping work, poor bending torque overload capacity, long maintenance and replacement time, etc., to achieve suitable for popularization and use, and high reliability , the effect of low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

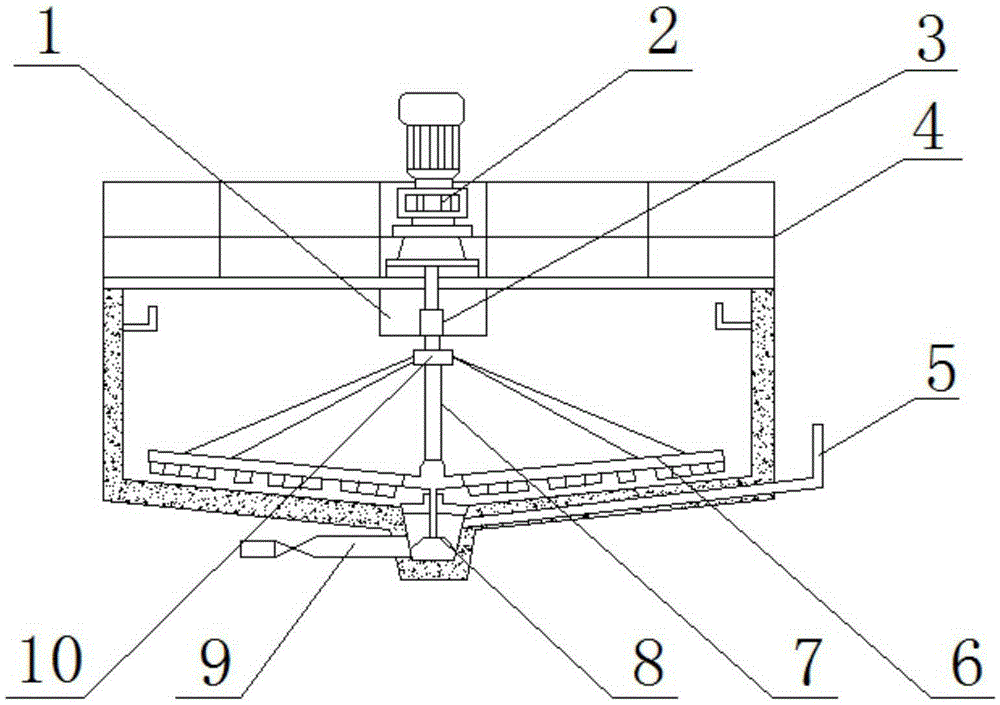

[0017] Example: such as figure 1 As shown, a clarifier mixing mud scraper includes a steady flow cylinder 1, a reducer 2, a sleeve coupling 3, a working bridge 4, a lubricating water pipe 5, a rake frame 6, a transmission shaft 7, a mud scraper 8, The mud discharge pipe 9 and the connecting flange 10, one end of the speed reducer 2 is arranged inside the steady flow cylinder 1 and the bottom end of the speed reducer 2 is connected with the transmission shaft 7, and the steady flow cylinder 1 is arranged inside the working bridge 4, One end surface of the transmission shaft 7 is fixed with a sleeve coupling 3 and the transmission shaft 7 runs through the bottom of the steady flow cylinder 1 .

[0018] As a technical optimization solution of the present invention, the other end surface of the transmission shaft 7 is provided with a connecting flange 10 and a plurality of steel wire ropes are connected to the connecting flange 10 .

[0019] As a technical optimization solution o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com