Liquid metal three-dimensional circuit and its manufacturing method based on 3D printing technology

A liquid metal and three-dimensional circuit technology, applied in the fields of printed circuit manufacturing, printed circuit, electrical components, etc., can solve the problems of high equipment cost and maintenance cost, low product qualification rate, and influence on circuit accuracy, etc., and achieve economical personalized design , Reduce production costs, simplify installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

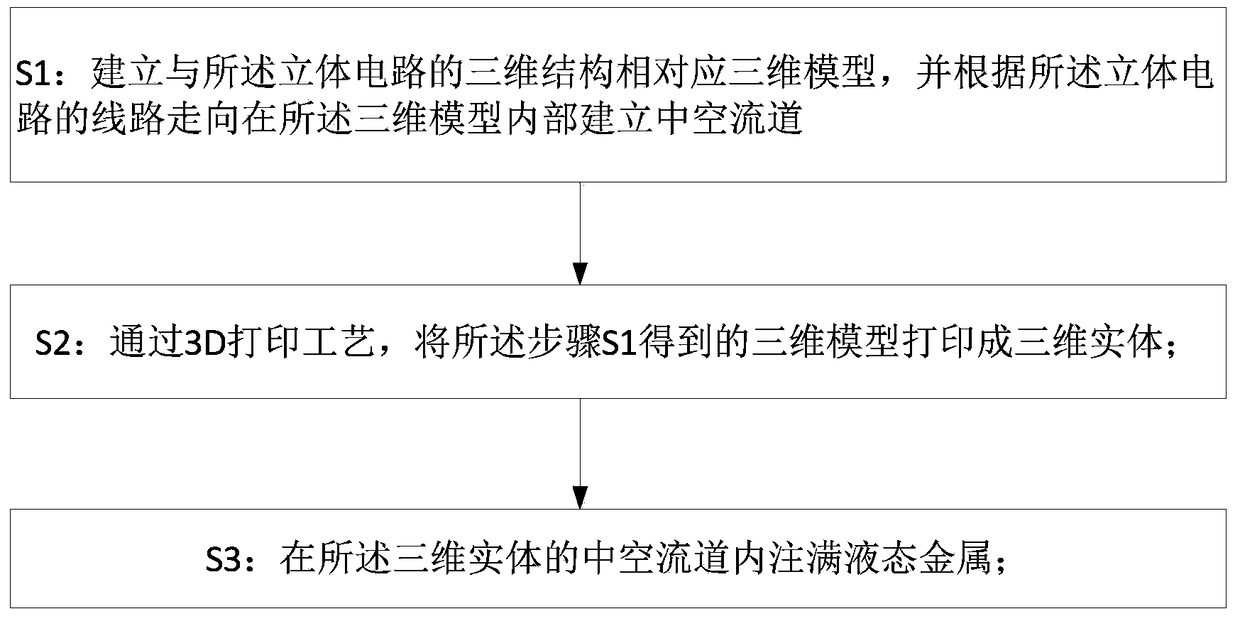

[0034] Such as figure 1 Shown, a kind of liquid metal three-dimensional circuit manufacturing method based on 3D printing technology, comprises the following steps:

[0035] S1: Establish a three-dimensional model corresponding to the three-dimensional structure of the three-dimensional circuit to be manufactured, and establish a hollow flow channel inside the three-dimensional model according to the line direction of the three-dimensional circuit;

[0036] S2: Print the three-dimensional model obtained in step S1 into a three-dimensional entity through a 3D printing process;

[0037] S3: filling the hollow channel of the three-dimensional solid with liquid metal;

[0038] Specifically, step S1: according to the design requirements of the three-dimensional circuit, use computer three-dimensional modeling software such as UG NX, Solidworks, ProEWildfire, etc. to establish a three-dimensional model corresponding to the three-dimensional structure of the three-dimensional circui...

Embodiment 2

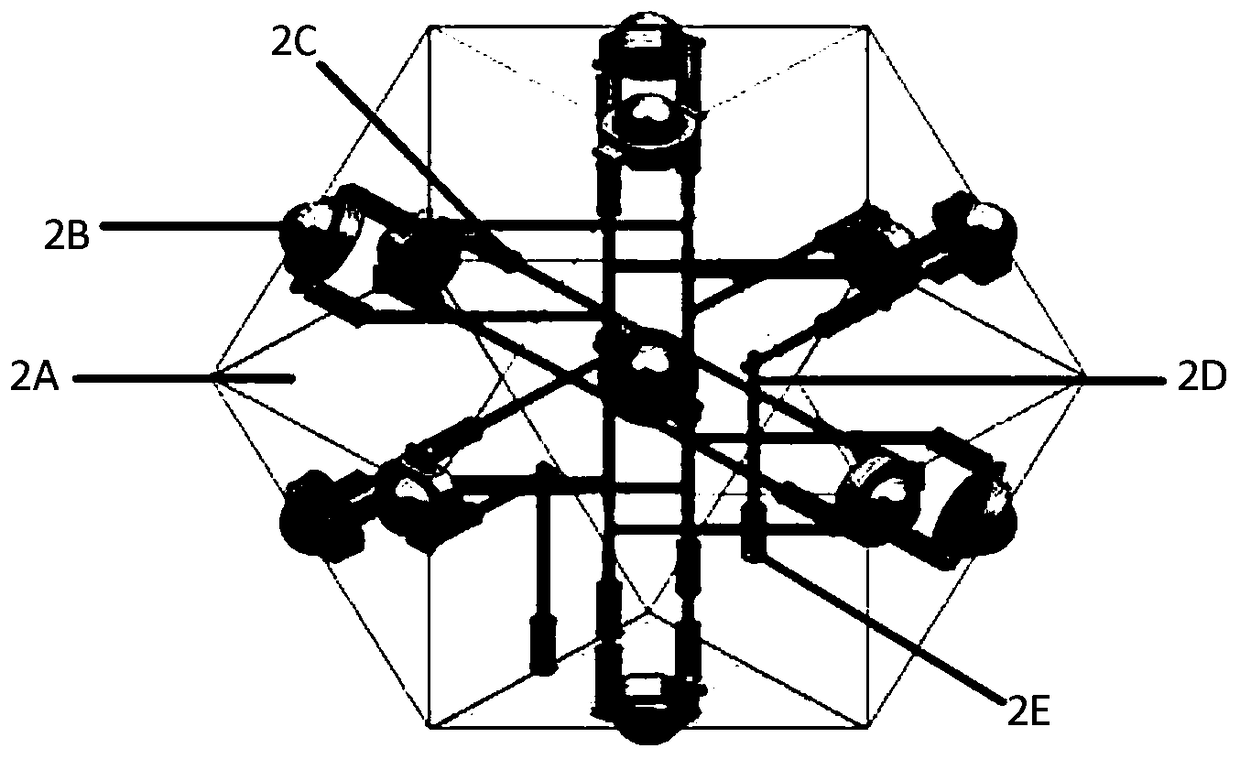

[0045] On the other hand, the present invention also provides a three-dimensional circuit made by the manufacturing method of Embodiment 1, for example: as figure 2 The multi-faceted LED flexible three-dimensional lamp holder shown

[0046] Wherein, adopt the manufacturing method of embodiment 1 to make the steps of multifaceted LED flexible three-dimensional lamp holder as follows:

[0047] Step 1: According to the design requirements of the multi-faceted LED flexible three-dimensional lamp holder, use the computer 3D modeling software UGNX10.0 to construct and figure 2 The three-dimensional model corresponding to the three-dimensional structure of the multi-faceted LED flexible lamp holder 2A is shown, and a hollow flow channel with a circular cross-sectional shape and a cross-sectional diameter of 1mm is created inside the model according to the design direction of the conductive circuit inside the lamp holder. The two ends of the device are respectively provided with a ...

Embodiment 3

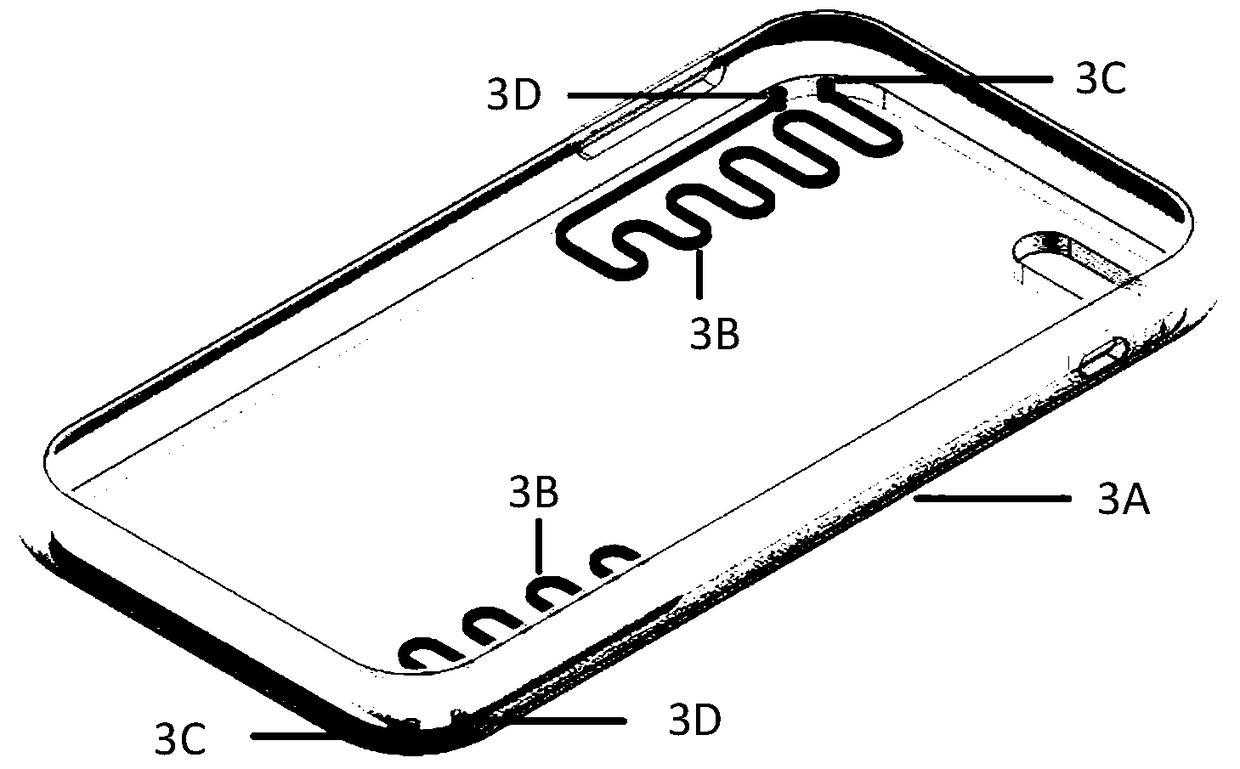

[0053] The present invention also provides a three-dimensional circuit made by the manufacturing method of Embodiment 1, for example: as image 3 Shown, a flexible phone case with a built-in antenna.

[0054] Wherein, adopt the manufacturing method of embodiment 1 to make the flexible mobile phone case that contains built-in antenna, the steps are as follows:

[0055] Step 1: According to the design requirements of the flexible mobile phone case with built-in antenna, use the computer 3D modeling software UGNX10.0 to construct and image 3 The three-dimensional three-dimensional model corresponding to the three-dimensional structure of the flexible mobile phone case 3A with a built-in antenna is shown, and a hollow flow channel with a square cross-sectional shape and a cross-sectional size of 1mm is created inside the model according to the circuit design direction of the built-in antenna. The two ends are respectively provided with a filling port and an exhaust port with a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com