A cement combined semi-finish grinding optimization control system and method

An optimized control, cement technology, applied in the direction of comprehensive factory control, electrical program control, comprehensive factory control, etc., can solve problems such as gaps, and achieve the effects of large mill current, stable quality, and reasonable cement particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

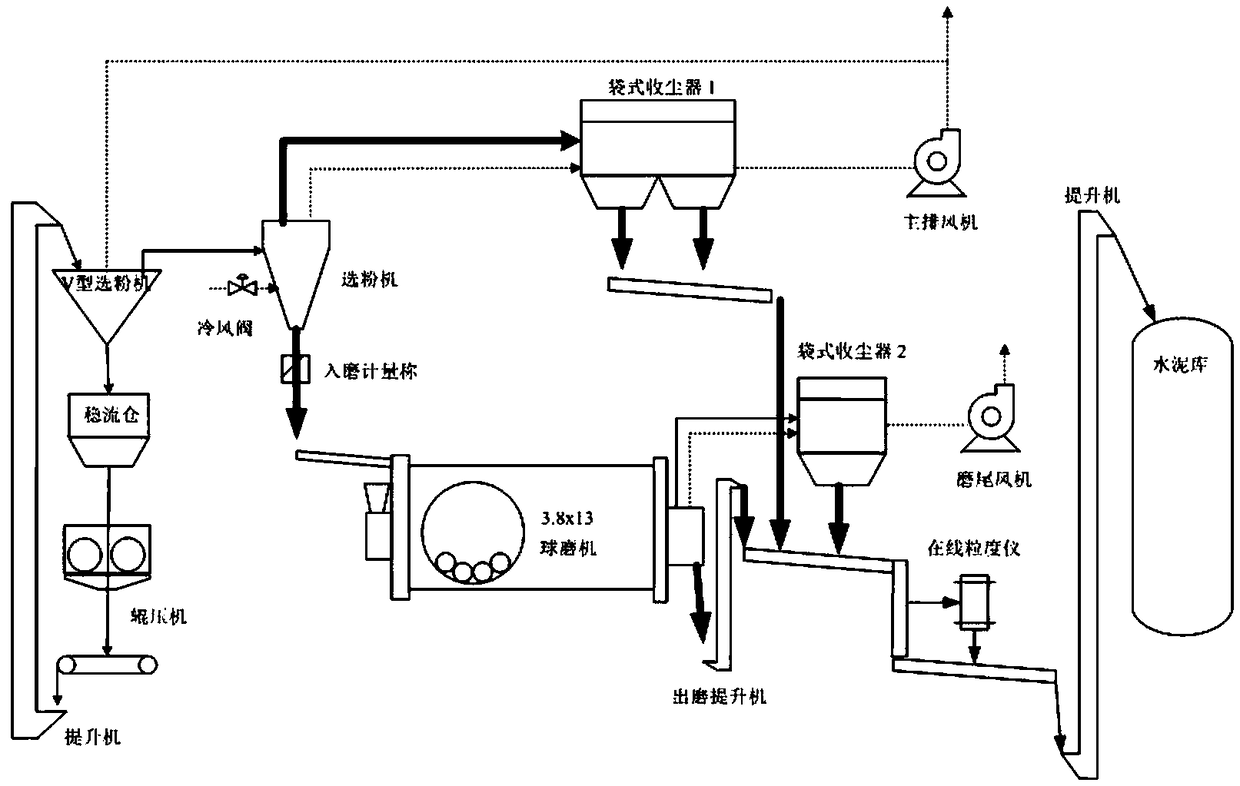

[0119] Such as figure 1 As shown, clinker, slag, fly ash and other materials are mixed in a certain proportion, and then slowly enter the roller press through the steady flow of the steady flow bin. The roller press squeezes the material. After being extruded by the roller press, the fine particles in the material are selected by the powder separator, and then are drawn into the bag filter 1 by the main exhaust fan, and then directly enter the cement silo. The coarser materials selected by the classifier enter the ball mill for grinding, and the qualified cement after grinding is sucked into the bag filter 2 by the tail fan, and then enters the cement storage. The metering scale under the powder classifier weighs and measures the materials entering the ball mill. The opening of the cold air valve can adjust the negative pressure in the powder separator. When the opening of the cold air valve becomes larger, the negative pressure in the powder separator becomes smaller, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com