Equipment leak detection experimental system and method under pressure environment maintenance conditions

A leak detection and experimental system technology, applied in the field of nuclear equipment experiments, can solve problems such as the inability to meet equipment leak detection requirements, and achieve the effect of maintaining stable pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

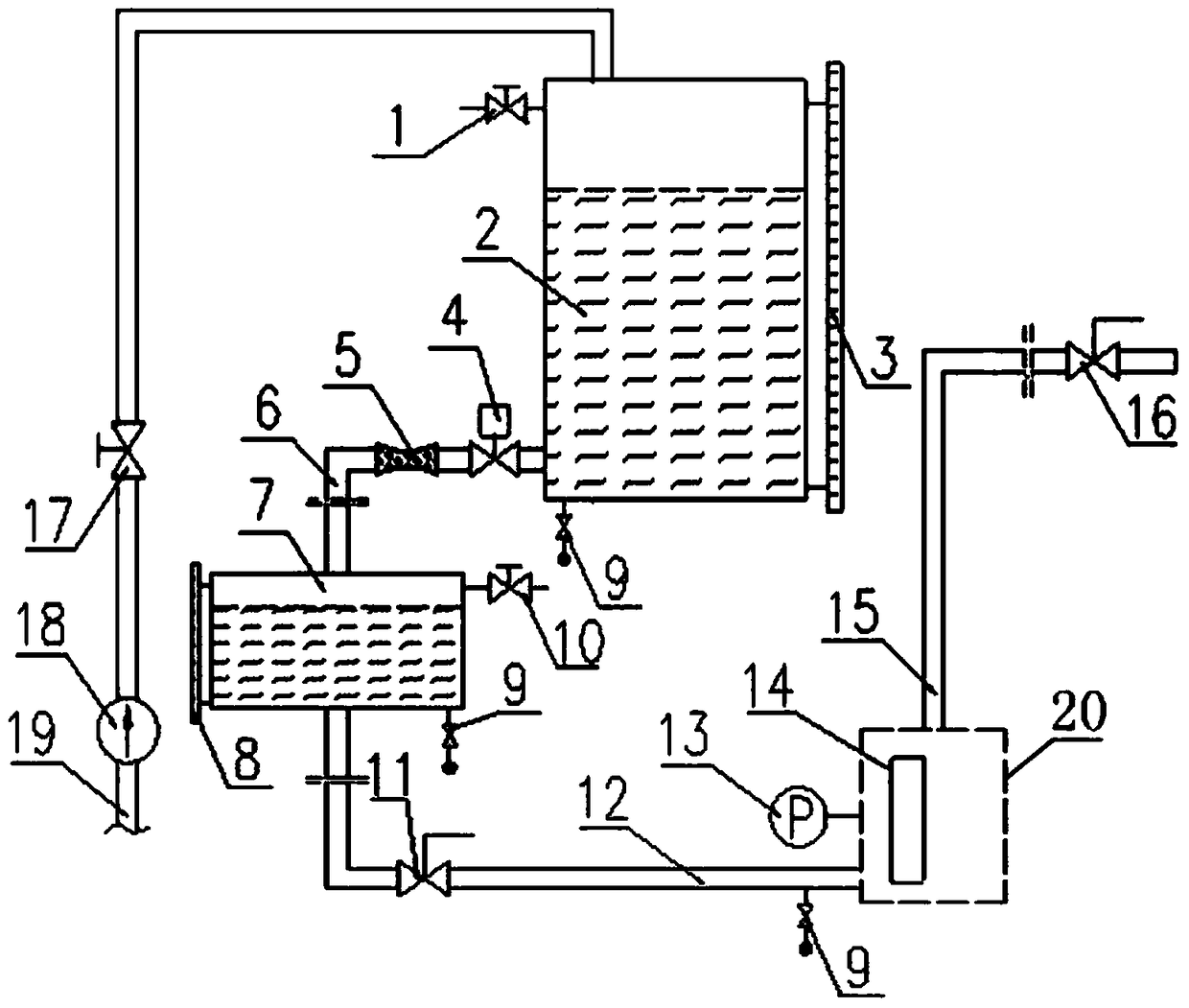

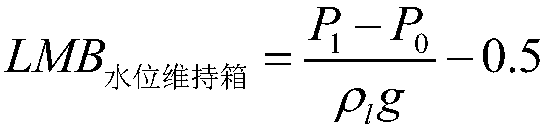

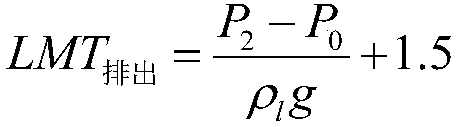

[0043] Such as figure 1 As shown, the present invention is an equipment leakage detection experimental system under pressure environment maintenance conditions, including a water storage tank 2, a water level maintenance tank 7, a back pressure water tank 20 and a pressure test container 20. The side of the water storage tank 2 is installed with a storage tank. The water tank level gauge 3 is installed near the top of the water storage tank 2 with a water storage tank overflow valve 1; the water level maintaining tank 7 is installed on the side of the water level maintaining tank 7 with a water level maintaining tank level gauge 8 installed near the top of the water level maintaining tank 7 Water level maintenance tank overflow valve 10; back pressure water tank 20 is equipped with a back pressure water tank level gauge 21, a back pressure water tank overflow valve 22 is installed near the top of back pressure water tank 20; pressure test container 20 is provided with heating c...

Embodiment 2

[0050] Such as figure 1 As shown, an experiment method for device leakage detection at a lower pressure under the condition of maintaining a fine pressure environment using the above-mentioned experimental system meets the leakage detection requirements of devices with lower design pressure.

[0051] Install, connect and fix a device leak detection experimental system with a lower pressure under the pressure environment maintenance condition in Example 1.

[0052] First, install and fix the pressure test container 20 as needed, and set a pressure transmitter 13 at the entrance of the pressure test container 20 to monitor the pressure value of the pressure test container 20 in real time. The discharge pipe 12 is installed at the outlet position of the pressure test container 20. At this time, the back pressure water tank 20, the back pressure water tank level gauge 21, the back pressure water tank overflow valve 22, and the back pressure water tank connecting pipe 23 may not be use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com