Carbon fiber short-cut production line sizing device

A carbon fiber and production line technology, applied in the field of chopped carbon fiber production equipment, can solve the problems of poor wettability between carbon fiber and resin, unsmooth production, and decline in carbon fiber quality, and achieve low manufacturing and use costs, intuitive sizing effect, and easy loading and unloading Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings. This embodiment is only used to explain the present invention and does not limit the protection scope of the present invention.

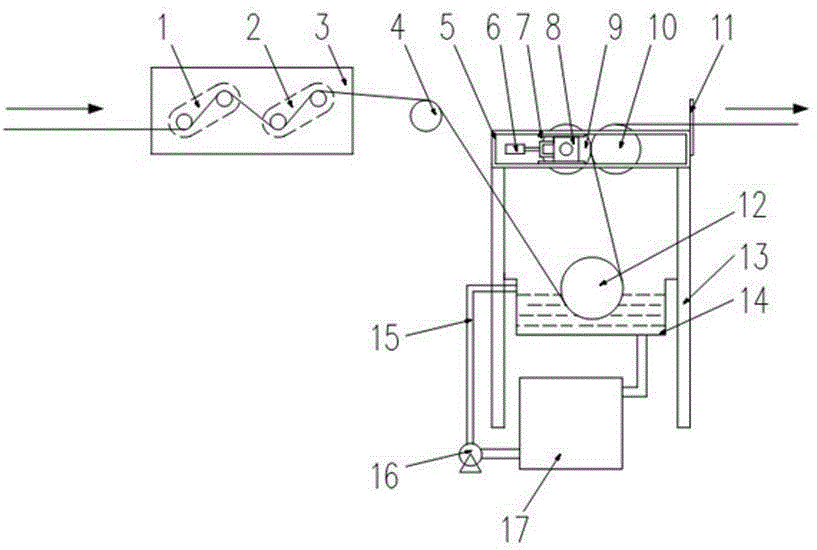

[0019] Such as figure 1 As shown, a carbon fiber chopped production line sizing device includes a panel 3 provided with a tension adjustment device, a godet 4, a frame 13, a rectangular frame 5 fixed on the upper end of the frame 13, and a rectangular frame 5 located at the upper end of the frame 13. Below is the sizing tank 14 fixedly connected to the frame 13 by bolts. The frame 13 is made of aluminum profiles and fixed on the ground through aluminum profile anchor connectors. The sizing tank 14 is provided with The sizing roller 12 partially immersed in the sizing liquid, the rectangular frame 5 is provided with a sizing device that squeezes out the excess sizing on the carbon f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com