Electrophoretic paint bath liquid computer automatic maintenance system

An automatic maintenance, electrophoresis tank technology, used in electrophoresis plating, electrolytic coatings, coatings, etc., can solve the problems of waste of organic solvent electrophoresis resin, environmental protection substandard, waste of the environment, etc., to avoid pollution of ion exchange resin, ensure resistance Effects of organic solvent capacity, guaranteed pressure and flow requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

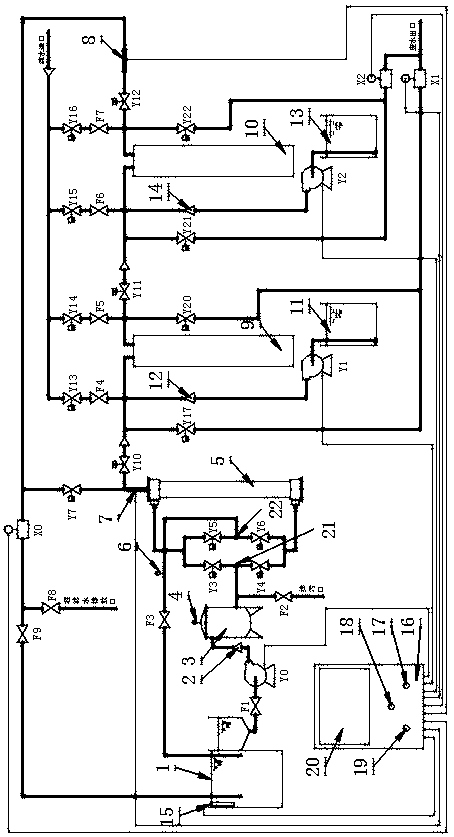

[0010]An electrophoretic paint tank computer automatic maintenance system, the system includes an electrophoresis tank 1 and a control 16, the automatic operation of the entire system is controlled by the program in the PLC display screen 20 on the control box 16, and the control box 16 also includes a power switch 17, Sound and light alarm 18, emergency stop switch 19; the auxiliary tank on the electrophoresis tank 1 is connected to the paint inlet valve F1, the ultrafiltration pump Y0, the ultrafiltration pump check valve 2, the stainless steel bag filter 3, and the stainless steel bag filter through pipelines. The upper part of the filter 3 is provided with a filter pressure gauge 4, and the paint outlet of the lower part of the stainless steel bag filter 3 is provided with a drain valve F2 through a tee on one side, and the other side is connected to an ultrafiltration reverse paint inlet solenoid valve Y3 through a paint inlet tee 21 , Ultrafiltration forward paint inlet s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com