Waterborne one-component coating and preparation method thereof

A one-component, coating technology, applied in the field of wood lacquer, can solve the problems of small dosage, can not play a significant role, large dosage, storage stability and other problems, achieve good fullness, fast drying, improved collapse resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

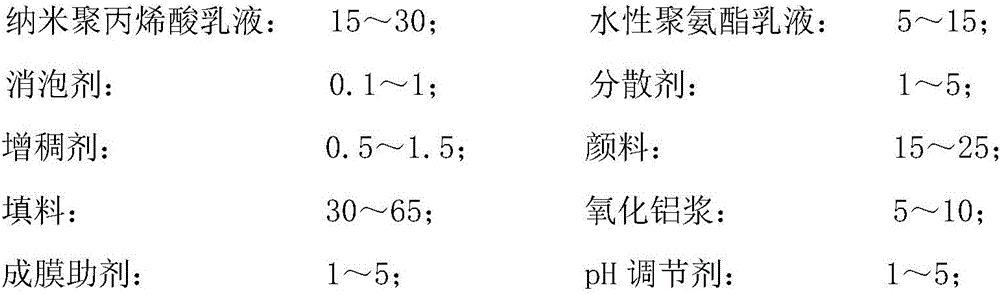

Image

Examples

Embodiment 1

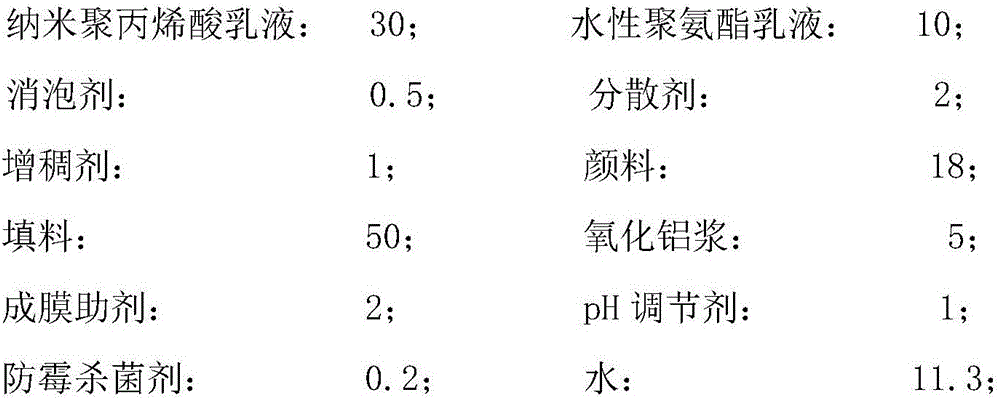

[0037] Embodiment 1: a kind of waterborne one-component paint, it is made up of the raw material of following weight part:

[0038]

[0039] Wherein, the alumina slurry is composed of the following raw materials in parts by weight: nano-alumina powder: 20; Tego715W: 2; BYK094: 0.1; Thixol 53L: 0.5; deionized water: 60.

[0040] The preparation method of above-mentioned waterborne one-component paint, it may further comprise the steps:

[0041] S1. Weighing: Weigh each raw material according to the proportion of the above formula, and set aside;

[0042] S2. Preparation of alumina slurry: take the raw material of alumina slurry, disperse deionized water, BYK094, Tego715W and Thixol53L at a speed of 500rad / min for 5min, add nano-alumina powder, adjust the speed to 950rad / min, and disperse 20min;

[0043] S3. Dispersion: Disperse PR-3500, Oubaodi 995, Thixol 53L, AMP-95, and dipropylene glycol methyl ether at a speed of 950rad / min until the oil shrinks, then add Tego715W, TS...

Embodiment 2

[0044]Embodiment 2: a kind of waterborne one-component coating, it is made up of the raw material of following weight part:

[0045]

[0046]

[0047] Wherein, the alumina slurry is composed of the following raw materials in parts by weight: nano-alumina powder: 26; Tego740W: 3; BYK024: 0.5; Coapur830w: 1; deionized water: 72.

[0048] The preparation method of above-mentioned waterborne one-component paint, it may further comprise the steps:

[0049] S1. Weighing: Weigh each raw material according to the proportion of the above formula, and set aside;

[0050] S2. Preparation of alumina slurry: take the raw material of alumina slurry, disperse deionized water, YK024, Tego740W and Coapur830w at a speed of 700rad / min for 7.5min, add nano alumina powder, adjust the speed to 1100rad / min, Disperse for 25 minutes;

[0051] S3. Dispersion: Disperse HEXIOM3000, Oubaodi 995, Coapur830w, AMP-95, and dipropylene glycol butyl ether at a speed of 1100rad / min until the oil shrinks,...

Embodiment 3

[0052] Embodiment 3: a kind of waterborne one-component paint, it is made up of the raw material of following weight part:

[0053]

[0054] Wherein, the alumina slurry is composed of the following raw materials in parts by weight: nano-alumina powder: 25; Tego760W: 5; TEGO foamex 810: 0.8; RM-8W: 2; deionized water: 80.

[0055] The preparation method of above-mentioned waterborne one-component paint, it may further comprise the steps:

[0056] S1. Weighing: Weigh each raw material according to the proportion of the above formula, and set aside;

[0057] S2. Preparation of alumina slurry: take the raw material of alumina slurry, disperse deionized water, TEGO foamex 810, Tego760W and RM-8W at a speed of 600rad / min for 10min, add nano-alumina powder, and adjust the speed to 1000rad / min, disperse for 30min;

[0058] S3. Dispersion: Disperse PR-3500, Oubaodi 995, RM-8W, ammonia water, diethylene glycol monobutyl ether at a speed of 1000rad / min until the oil shrinks, then a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com