Variable rope tethered double cylinder winch hoisting system and transformation method for tethering rope

A lifting system and double-drum technology, applied in portable lifting devices, clockwork mechanisms, hoisting devices, etc., can solve the problems of low efficiency and heavy manual operation workload, and achieve high safety performance, ingenious structural design, and structural Design novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

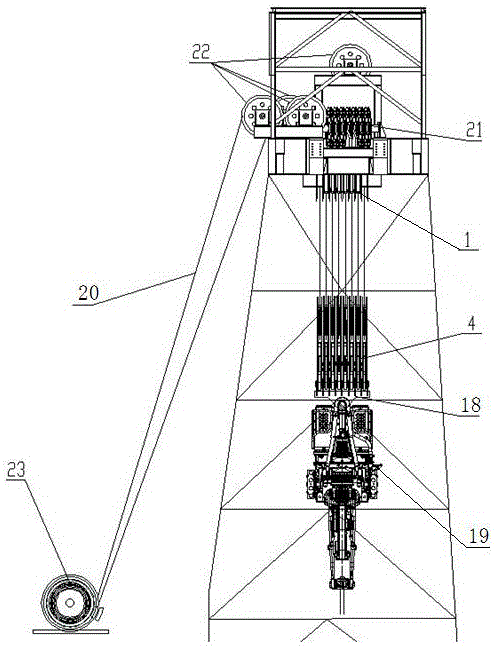

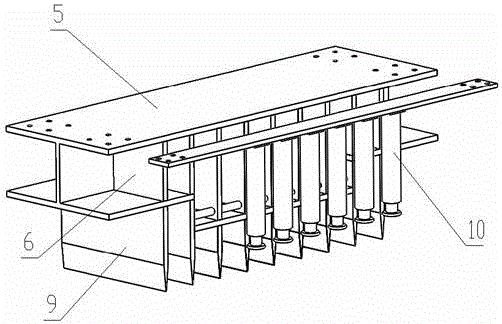

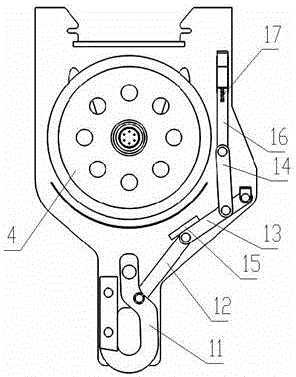

[0042] Such as Figure 5 As shown, a double-drum winch hoisting system with variable ropes 12 ropes conversion method, the movable pulley block composed of eight single pulley blocks 4 is coordinated by the upper locking device 1 and the lower hook locking device 2 , the two single-pulley traveling carriages 4 that are controlled in the center are fixed at the bottom of the upper locking device 1 to become movable pulleys, and the rope system of the hoisting system is transformed, and the specific process is as follows:

[0043] Step 1. Under the action of the double-drum winch 23, all the single-pulley tourist cars 4 move upward synchronously and work together to lift the tourist car bracket 18 and the top drive 19. Except for the two outermost single-pulley tourist cars 4, other single-pulley tourist cars 4 The traveling blocks 4 are all in contact with the upper locking device 1, and the bottom end of the second cylinder 10 is in contact with the top of the guide rod 16 ins...

Embodiment 2

[0048] Such as Figure 6 As shown, a double-drum winch hoisting system with variable ropes 8 ropes conversion method, the movable pulley traveling block composed of eight single pulley traveling blocks 4 cooperates with the upper locking device 1 and the lower hook locking device 2 , control the centered four single-pulley traveling carriages 4 and fix their positions at the bottom of the upper locking device 1 to become movable pulleys for the rope transformation of the hoisting system. The specific process is as follows:

[0049] Step 1. Under the action of the double-drum winch 23, all the single-pulley tourist cars 4 move upward synchronously and work together to lift the tourist car bracket 18 and the top drive 19. Except for the two outermost single-pulley tourist cars 4, other single-pulley tourist cars 4 The traveling blocks 4 are all in contact with the upper locking device 1, and the bottom end of the second cylinder 10 is in contact with the top of the guide rod 16 ...

Embodiment 3

[0054] Such as Figure 7 As shown, a double-drum winch hoisting system 4 rope change method with variable ropes, the movable pulley block composed of eight single pulley blocks 4 cooperates with the upper locking device 1 and the lower hook locking device 2 , control the centered six single-pulley traveling carriages 4 and fix their positions at the bottom of the upper locking device 1 to become movable pulleys for the rope transformation of the hoisting system. The specific process is as follows:

[0055] Step 1. Under the action of the double-drum winch 23, all the single-pulley tourist cars 4 move upward synchronously and work together to lift the tourist car bracket 18 and the top drive 19. Except for the two outermost single-pulley tourist cars 4, other single-pulley tourist cars 4 The traveling blocks 4 are all in contact with the upper locking device 1, and the bottom end of the second cylinder 10 is in contact with the top of the guide rod 16 installed inside the corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com