Inflation and tyre repairing integrated machine

An all-in-one, tire repair technology, used in vehicle maintenance, vehicle repair/repair, transportation and packaging, etc., can solve problems such as easy misoperation, easy confusion of inflation and tire repair functions, and achieve fast tire repair and easy rotation. Replacing plastic bottles to maximize utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

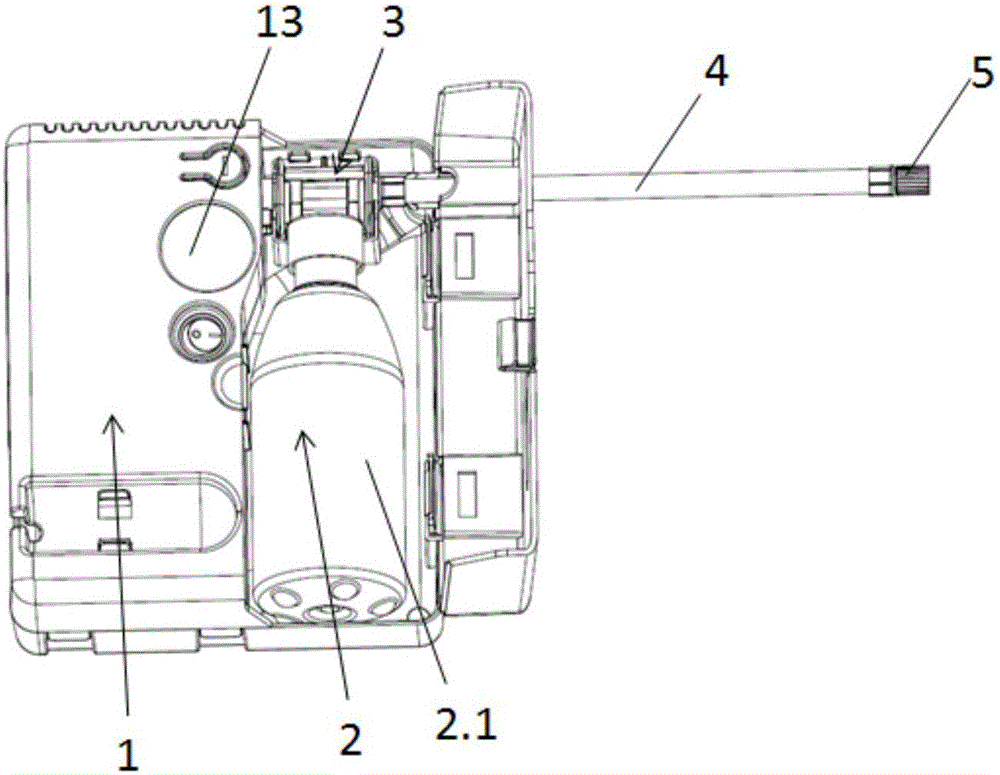

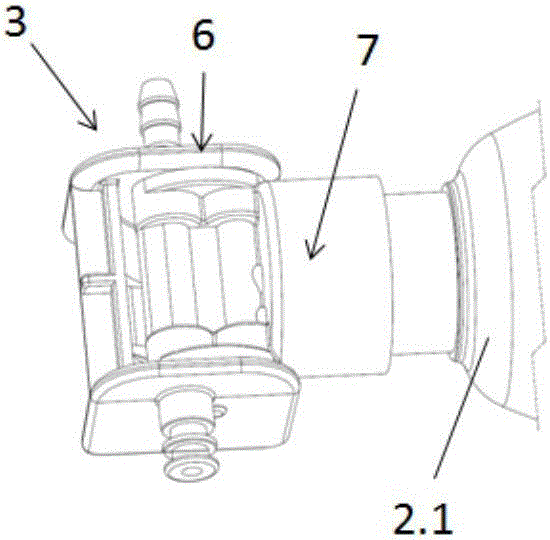

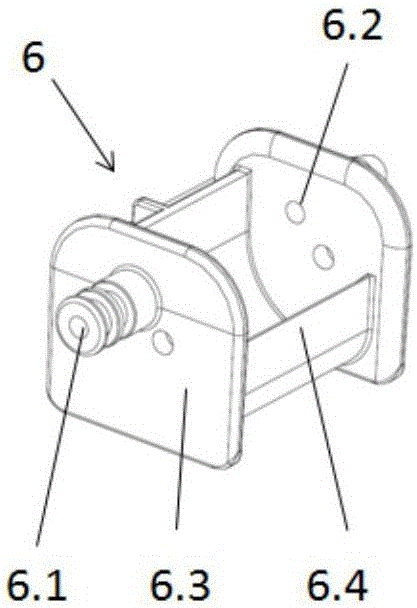

[0055] The specific embodiment of the present invention is an all-in-one machine for tire inflation and tire repair, such as figure 1 As shown, it includes an air supply unit 1, a tire repair unit 2, a conversion device 3 (abbreviated as a conversion device) for inflation and tire repair, and the conversion device 3 is used to connect the air supply unit, the tire repair unit and the output pipe 4 of the tire, and the output pipe 4 is connected with the tire through the valve joint 5, and the tire repairing unit 2 comprises the rubber bottle 2.1, and the tire repairing liquid is housed in the rubber bottle 2.1. The all-in-one machine for inflating and repairing tires in this specific embodiment also includes an air pressure gauge 13 for measuring the air pressure in the tire. Conversion device 3 such as Figure 2a As shown, it includes a base 6 and a three-way bottle cap 7, and the three-way bottle cap 7 communicates with the glue bottle 2.1 of the tire repair unit 2. base 6...

specific Embodiment approach 2

[0071] The all-in-one machine for inflating and repairing tires in this specific embodiment is a deformation of specific embodiment 1. There is no sealing cap at the bottle mouth of the rubber bottle of the tire repairing unit, such as Figure 11 As shown, the second air outlet hole 7.2A and the liquid outlet hole 7.3A of the bottle cap are directly connected with the glue bottle. The ports where the second air outlet hole 7.2A and the liquid outlet hole 7.3A communicate with the plastic bottle are respectively provided with an anti-backflow sealing ring and a liquid blocking plug. In this specific embodiment, the anti-backflow sealing ring and the liquid blocking plug are respectively the anti-backflow sealing sleeve 7.2.1 and the blocking plug 7.3.1.

[0072] When repairing tires, stand up the rubber bottle, open the air supply unit, the gas enters through the second air outlet 7.2A, open the anti-backflow sealing sleeve 7.2.1 under high pressure, the gas enters the rubber b...

specific Embodiment approach 3

[0075] The all-in-one machine for inflating and repairing tires in this specific embodiment is another modification of specific embodiment 1, such as Figure 12 As shown, the conversion device 3B of the inflatable tire repair machine includes a base 6B and a three-way bottle cap 7B, the three-way bottle cap 7B communicates with the glue bottle 2.1B, and the base 6B includes an air inlet 6.1B and a total air outlet 6.2B, the air inlet 6.1B and the total air outlet 6.2B are respectively connected with the air supply unit and the output pipe, and the base 6B itself is used as a horizontal rotation axis, and the three-way bottle cap 7B can be driven by the glue bottle 2.1B to The base 6B rotates the shaft in the vertical direction, such as Figure 13a and 13b shown. When the plastic bottle 2.1B lies flat, such as Figure 13a As shown, the all-in-one machine for inflating and repairing tires is in an inflated state. When the rubber bottle 2.1B stands up, as shown in Figure 13b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com