Tire structure

A technology for tires and skins, applied to tire parts, wheels, non-pneumatic tires, etc., can solve the problems of insufficient tire pressure, blowout, casualties, etc., and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the present invention, the specific composition of the present invention and the effects achieved are described in detail below in accordance with preferred embodiments, in conjunction with the accompanying drawings and figure numbers:

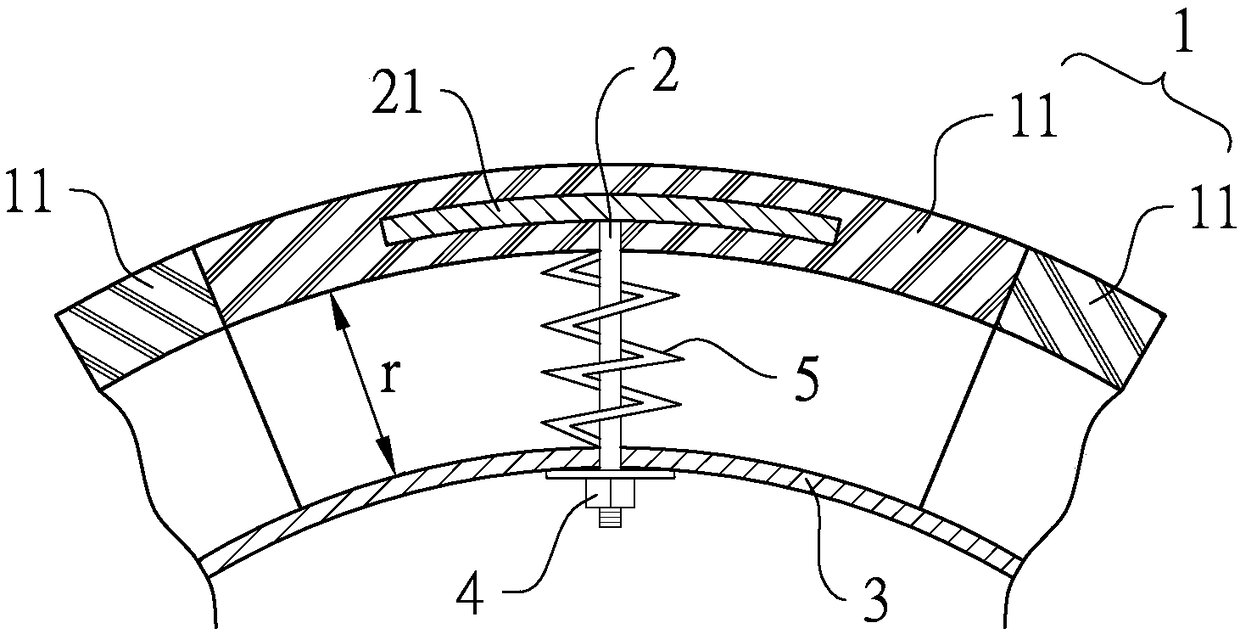

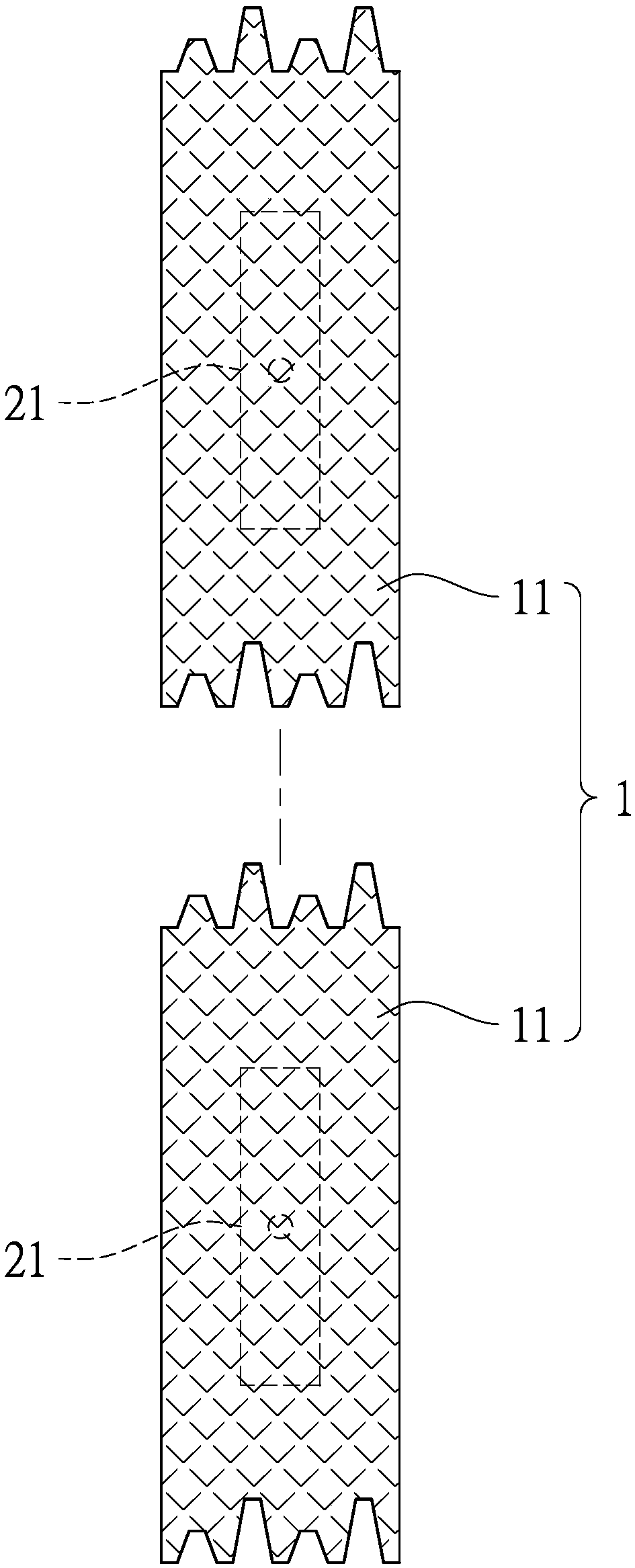

[0022] see Figure 1~3 , the content of the accompanying drawings is an embodiment of the tire structure of the present invention, which is composed of a tire body 1 and a plurality of T-shaped plugs 2 .

[0023] This tire body 1 is for being combined on the rim 3 of the wheel, and this tire body 1 is formed by connecting a plurality of skins 11, and among the plurality of T-shaped plug bodies 2, the top 21 of each T-shaped plug body 2 is for being covered. The coating is placed in each tire skin 11, and the parts where each tire skin 11 is connected to each other are set in a zigzag shape. And the end of each T-shaped bolt body 2 runs through the wheel frame 3 of the wheel, and is locked and fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com