A kind of preparation method of tin oxide dispersion reinforced silver-based electrical contact alloy

A technology of dispersion enhancement and electrical contact, applied in contacts, circuits, electric switches, etc., can solve the problems of easy segregation of particles and easy introduction of impurities, etc., and achieve high cost, good resistance to fusion welding and arc erosion, fine particle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

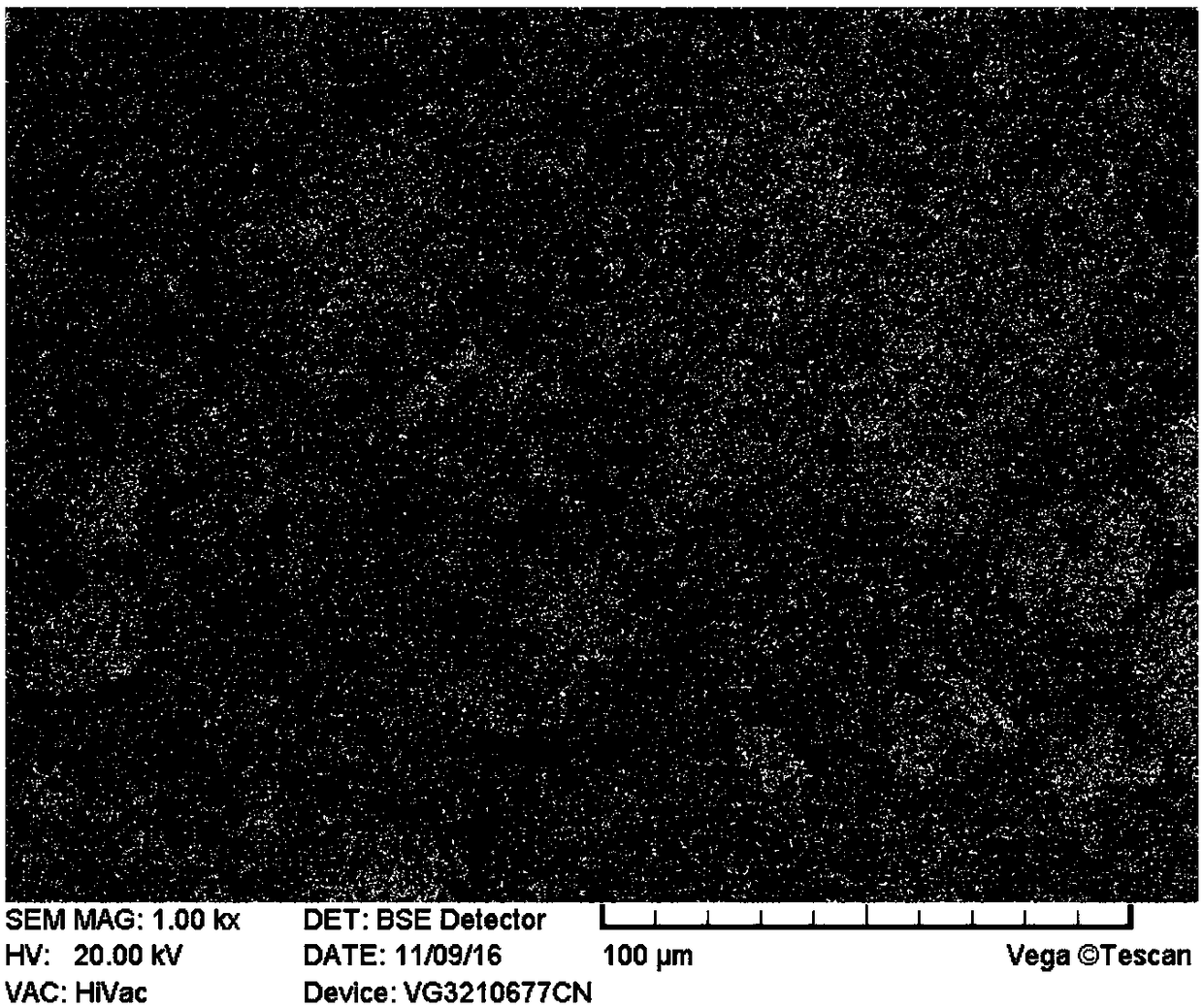

[0037] The preparation method of a silver tin oxide electrical contact alloy of the present invention adopts a sol-gel process, uses citric acid as a complexing agent to complex with a metal salt solution to form a sol-gel, and uses an ashless filter paper as a template to disperse the oxide The carrier controls the size of the gel. The silver-tin oxide composite powder is prepared first, and then the silver-tin oxide alloy is prepared. Compared with traditional preparation techniques, its advantages are:

[0038] (1) The internal oxides of the obtained alloy are evenly distributed and the particles are fine, and the alloy has good welding resistance and arc erosion resistance.

[0039] (2) It overcomes the disadvantages of high cost and uneven structure in the preparation of the current technology, and also avoids the problem that the oxides are prone to agglomeration during conventional mechanical powder mixing.

[0040] (3) Using ashless filter paper as a template as a di...

Embodiment 1

[0042] Step 1, preparing HNO for dissolving Sn powder 3 solution and AgNO 3 Mixture of solutions:

[0043] Add Sn powder to HNO with a mass fraction of 65% 3 Stir the solution evenly to obtain a Sn powder suspension. Slowly add the prepared Sn powder suspension to 1mol / L AgNO 3 aqueous solution to obtain a mixed solution. Among them, Sn powder and HNO 3 The ratio of the amount of substance is 3:2, Sn powder and AgNO 3 The ratio of the amount of substances is 1:1.

[0044] Step 2, add citric acid solution dropwise to the mixed solution and stir well:

[0045]The mixed solution prepared in step 1 was magnetically stirred at 65° C. for 2 hours, and 3 mol / L citric acid solution was added dropwise during the first half hour of stirring. Wherein the amount of citric acid substance and AgNO 3 The ratio to the sum of the amount of Sn powder is 1:1.

[0046] Step 3, impregnating ashless filter paper:

[0047] Fully soak 20 pieces of ashless filter paper in the mixed solution...

Embodiment 2

[0053] Step 1, preparing HNO for dissolving Sn powder 3 solution and AgNO 3 Mixture of solutions:

[0054] Add Sn powder to HNO with a mass fraction of 66% 3 Stir evenly in the solution to obtain a Sn powder suspension. Slowly add the prepared Sn powder suspension to 1.5mol / L AgNO 3 aqueous solution to obtain a mixed solution. Among them, Sn powder and HNO 3 The ratio of the amount of substance is 3:2, Sn powder and AgNO 3 The ratio of the amount of substances is 1:1.

[0055] Step 2, add citric acid solution dropwise to the mixed solution and stir well:

[0056] The mixed solution prepared in step 1 was magnetically stirred at 60° C. for 3 hours, and 4 mol / L citric acid solution was added dropwise during the first half hour of stirring. Wherein the amount of citric acid substance and AgNO 3 The ratio of the sum of the amount of the Sn powder and the amount of the substance is 2:1.

[0057] Step 3, impregnating ashless filter paper:

[0058] Fully soak 20 pieces of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com