Assembling method for large truss type pile leg structure

An assembly method and truss-type technology, applied in underwater structures, foundation structure engineering, sheet pile walls, etc., can solve the problems of high cost, large manpower, material resources, etc., reduce welding deformation, improve work efficiency, and facilitate welding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] First of all, same as the existing technology, for structural pipe fittings such as main side pipes, support pipes, inner horizontal pipes, etc. And realize the operation of extending the main side pipe.

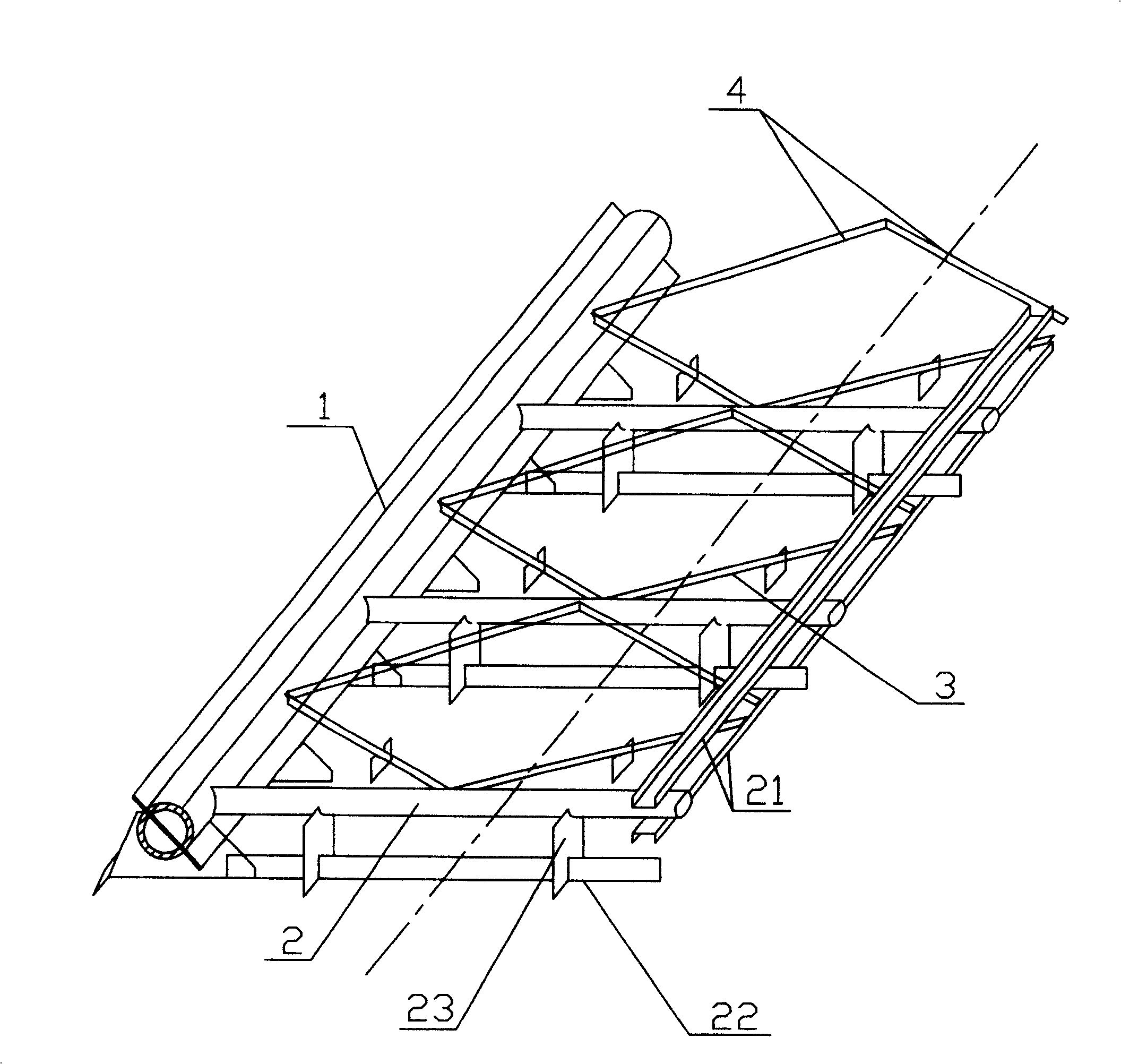

[0023] Thereafter, if figure 1 As shown, in the horizontal construction method, with the main side tube at one end as the reference, assemble the monolithic structure of each leg segment, the length of each monolithic structure is 15-25 meters, and the leg segment The length is the same, the optimal way is about 20 meters. Wherein, the assembling process of the monolithic structure is as follows: first, the horizontal pipe 2 is assembled with the main side pipe 1 as a reference, and then the lateral support pipe 3 is fixed between the horizontal pipe 2 and the main side pipe 1 . figure 1 Mark 4 in the middle indicates two support pipes, which are installed as loose parts in the segmented assembly stage so as to realize the final assembly. In addition, the open ends...

Embodiment 2

[0027]Including the process of lengthening of the main side pipe—single-piece assembly of leg segments—segmental assembly of legs—general assembly of leg segments—closing of leg segments / total segments, but in the final stage , That is to complete the segmental assembly of the legs and realize the closing stage of the total segment, the legs can be directly segmented from bottom to top in the vertical state.

Embodiment 3

[0029] First of all, for the main side pipe, support pipe, inner horizontal pipe and other structural blanking, the welding of the main side pipe and support pipe and other pipe fittings and the lengthening of the main side pipe are completed. Afterwards, in the horizontal construction method, the single-piece structure of each leg segment is assembled based on the main side tube at one end.

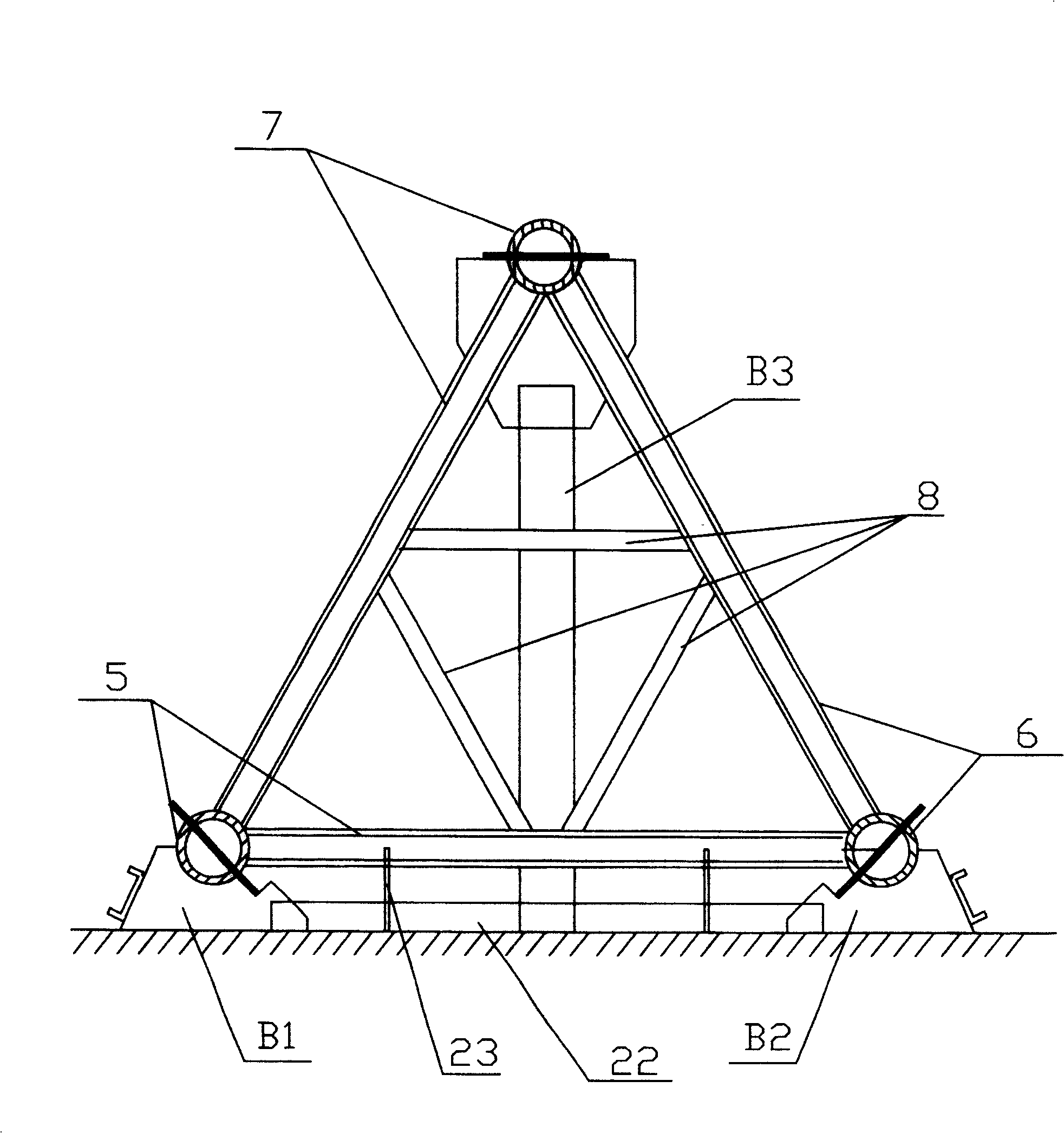

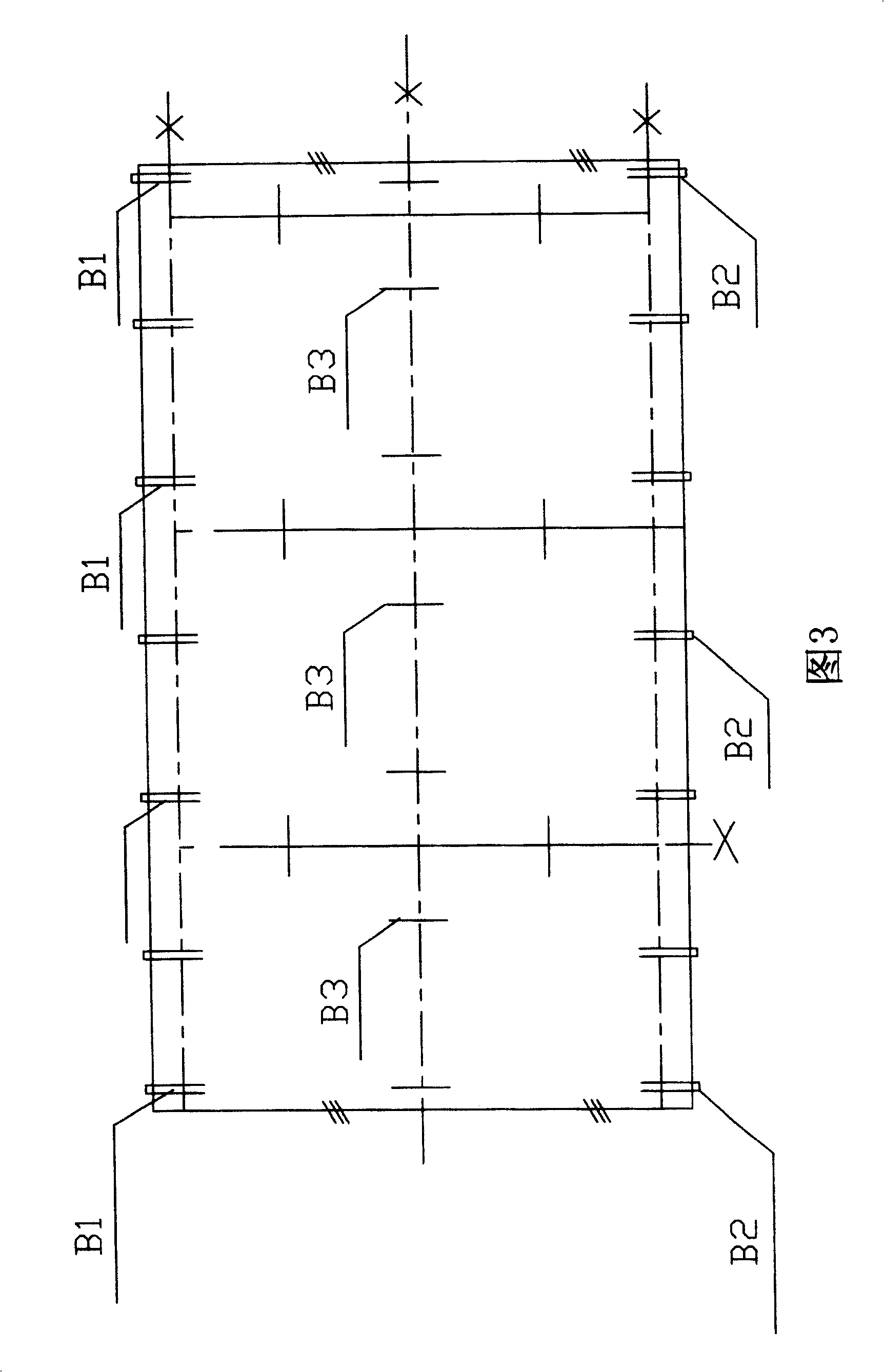

[0030] Thereafter, if figure 2 As shown, in the horizontal construction mode, three identical monolithic structures are assembled into regular triangular truss-type leg segments by using tire frame devices. The assembly process is preferably as follows: first fix a monolithic structure 5 in a horizontal position, then assemble the monolithic structure 6 at the lower end of the main side tube, and then assemble another monolithic structure 7, and finally fix the leg segments at a cross-section Diagonal support tubes 8 between the inner three horizontal tubes.

[0031] In the last step,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com