Power panel and power panel system

A technology of power supply board and power supply, which is applied in the direction of circuits, electrical components, electric processing equipment, etc., which can solve the problems of unfavorable system circuit board distribution, poor integration of DC power supply, unfavorable DC power supply maintenance, etc., so as to avoid scattered and unified system structure Configuration and maintenance, the effect of improving integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

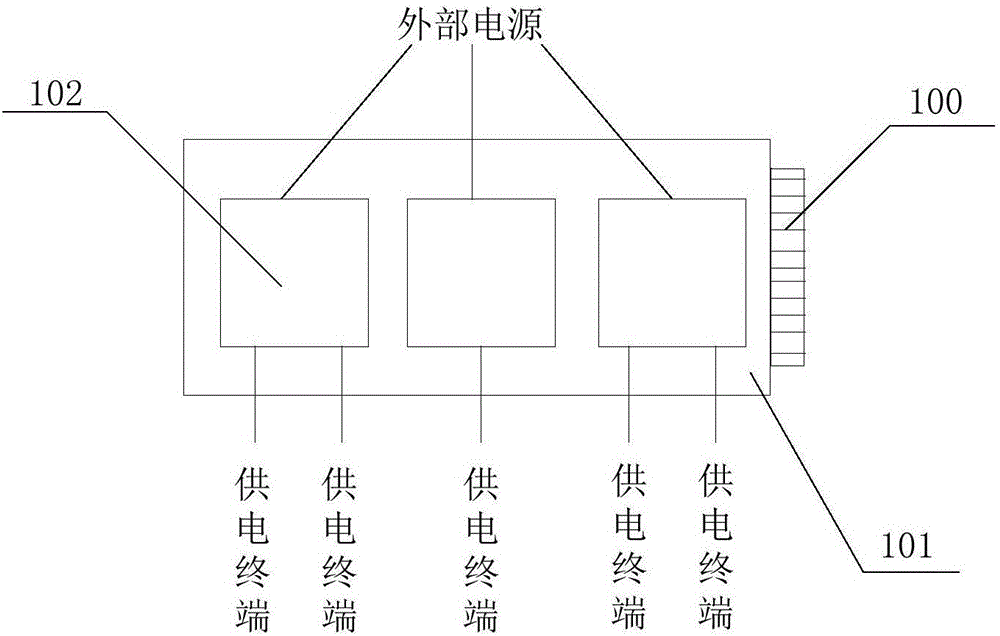

[0033] see figure 1 A schematic diagram of the structure of a power board is shown; the power board is used in the control system of an electric discharge machine tool, and one end of the power board is provided with a socket 100 that matches the slot of the main board of the control system to fix the power board on the motherboard;

[0034] The above-mentioned power board includes an insulating base plate 101 and a plurality of power packs 102 fixed on the insulating base plate; the power packs 102 are detachably connected to the insulating base plate 101; one end of the power pack 102 is connected to an external power source; the other end of the power pack 102 Connect with the power supply terminal (in actual implementation, one power supply group can be connected to one protection terminal, or one power supply group can be connected to two or more protection terminals); the working parameters of the power supply group 102 match the type of power supply terminal; The worki...

Embodiment 2

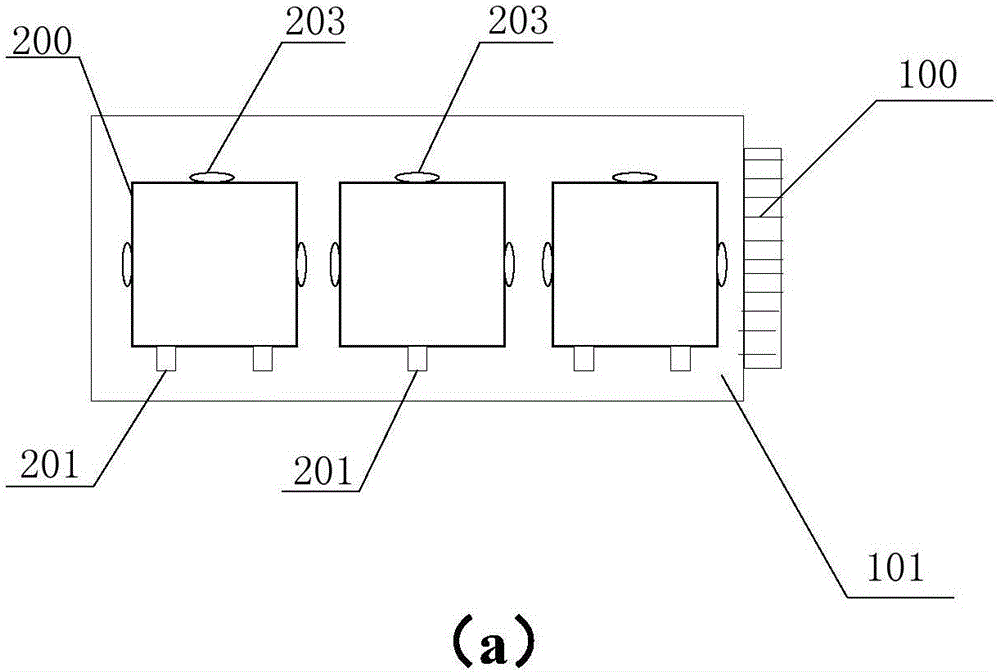

[0039] see figure 2 (a) The front view of the specific structural schematic diagram of the first type of power board; the insulating base plate of the power board is provided with a plurality of insulating shells 200; between adjacent insulating shells 200, there are set Safety distance; each insulating housing 200 is provided with a power supply interface 201; the insulating housing 200 is snap-connected with the insulating base plate (in actual implementation, multiple snap-fit parts 203 can be arranged on the outside of each insulating housing, figure 2 In (a), three buckle parts 203 are provided on the outside of each insulating housing as an example); the above-mentioned power pack is arranged in the insulating housing 200 ; the power pack supplies power to the power supply terminal through the power supply interface 201 .

[0040] In actual implementation, a power pack is installed in each insulating shell; in order to ensure that each power pack can work independent...

Embodiment 3

[0047] see image 3 The specific structural diagram of the second type of power board is shown; the power board is based on the power board provided in the first or second embodiment above, and the power group on the power board includes an external power interface 300, A three-phase rectification and filtering circuit 301, a high-frequency inverter circuit 302 and a rectification and filtering circuit 303; the rectification and filtering circuit 303 is connected to a power supply terminal. image 3 In the above, one power supply group is provided on the insulating board as an example. In actual implementation, multiple power supply groups are provided on the insulating floor, which is not limited in the present invention.

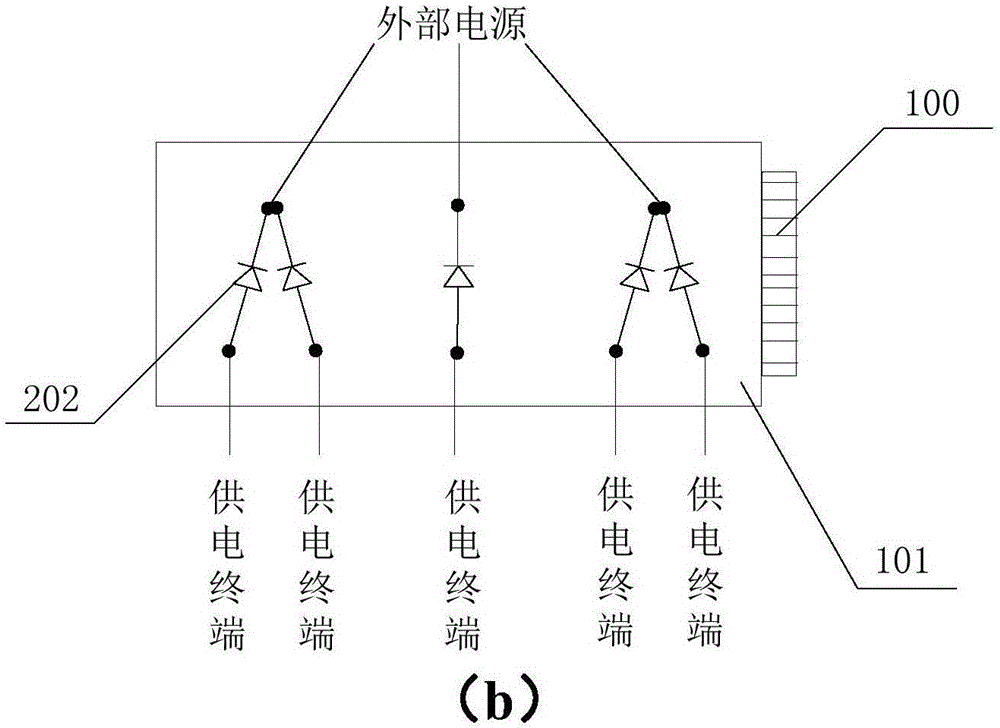

[0048] Specifically, see Figure 4 The circuit diagram of the three-phase rectification filter circuit is shown; the three-phase rectification filter circuit controls the common cathode group and the common anode group simultaneously, and its working prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com