Manufacturing method of common box type ring network cabinet

A manufacturing method and technology for ring network cabinets, which are applied in switchgear, electrical components, etc., can solve the problems of easy cracks and application limitations of common box ring network cabinets, and achieve the effect of reducing output temperature and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with embodiment technical solution of the present invention is further described:

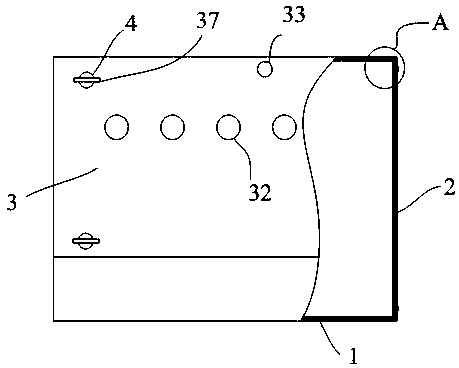

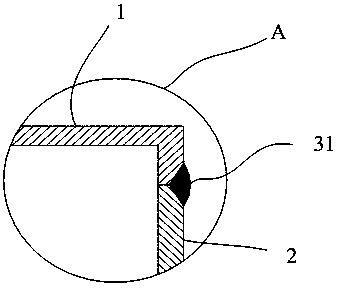

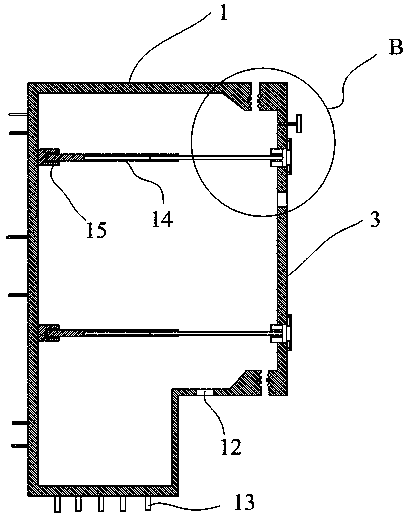

[0025] Such as figure 1 , figure 2 , image 3 and Figure 4 Shown: It is a schematic diagram of the structure of the common box-type ring network cabinet completed by this manufacturing process. The press-formed mounting plate 1 and sealing plate 3 are manufactured by butt sealing of the sealing structure, and the mounting plate 1 and side plate 2 are manufactured by welding. , the sealing structure is a flange strip 7 welded on the edge of the mounting plate 1, two sealing grooves 71 are opened on the flange strip 7 of the mounting plate 1, and a positioning groove 73 is opened before the two sealing grooves 71, and on the sealing plate 3 Two sealing rings 72 corresponding to the sealing groove are fixed on the flange strip 7, and the two sealing rings 72 are made with ribs that can be embedded in the sealing groove. Several threaded columns 13 are welded on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com