Assembly and encapsulation method of high-frequency elongate contact piece with cable

A contact and high-frequency technology, which is applied in the field of component potting, can solve the problems of difficult penetration of needles, difficult potting, slow filling, etc., and achieve the effect of ensuring no bubbles in the adhesive layer, ensuring reliability, and ensuring compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

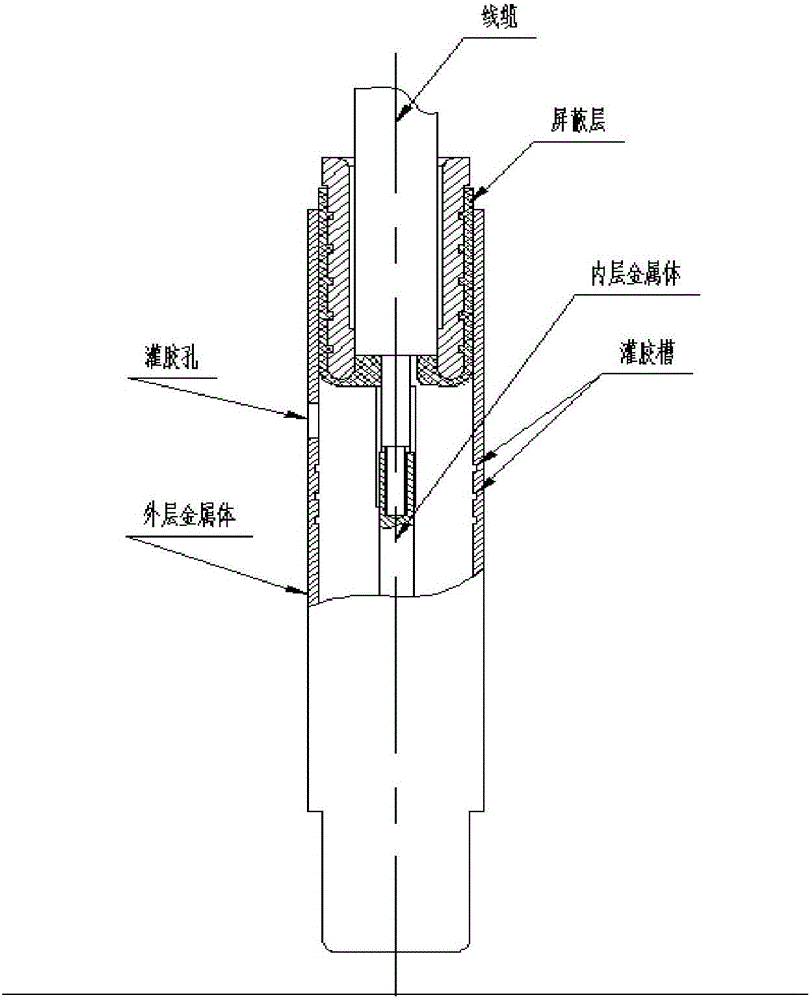

[0026] The technical solution adopted in the present invention is: (1) set up a plurality of grooves on the inner surface of the outer metal body around the position where the electrical connector needs to be filled with glue as glue filling grooves; A glue hole slightly smaller than the maximum diameter of the glue needle is opened on the outer metal body at -2mm;

[0027] (2) Assemble the cable and the electrical connector to form an unsealed high-frequency contact, observe whether the twisted pair of the cable is twisted through the glue hole, and adjust the twisted pair if twisted. ;

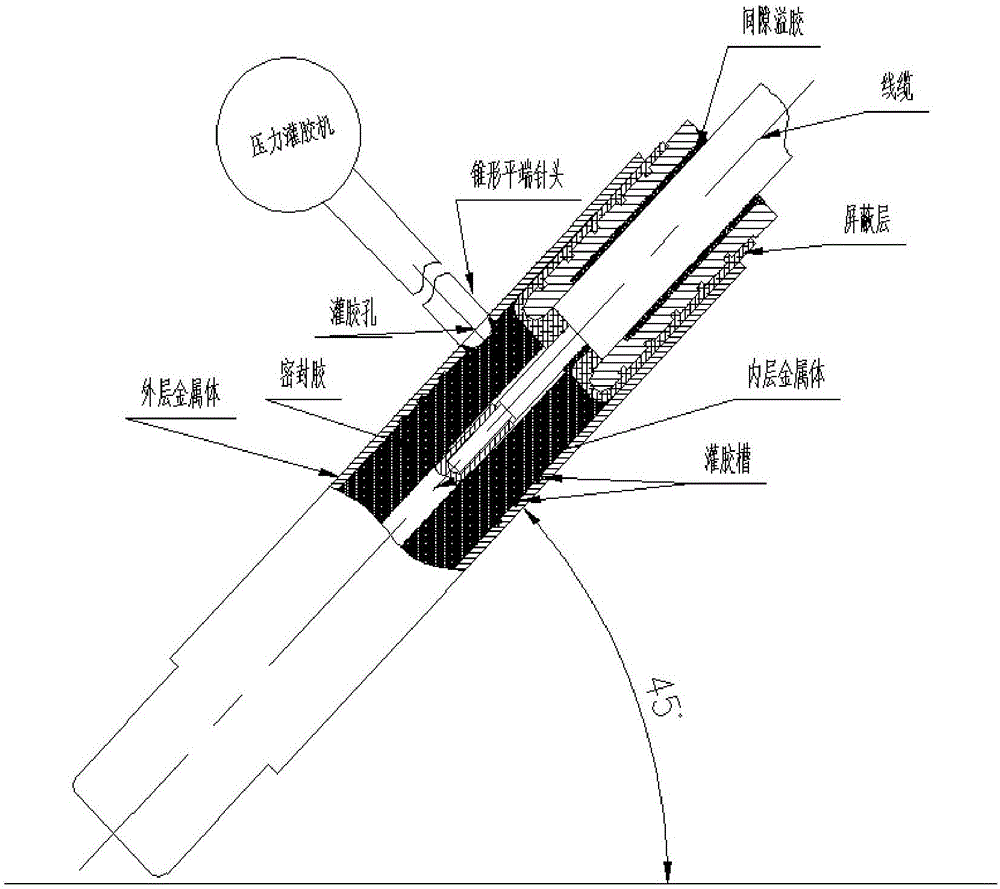

[0028] (3) Tilt the high-frequency contact piece at an angle of 45°, seal the glue filling needle with the glue filling hole of the electrical connector, and pressurize the glue until the glue overflows from the crimping part of the tail of the high-frequency contact piece;

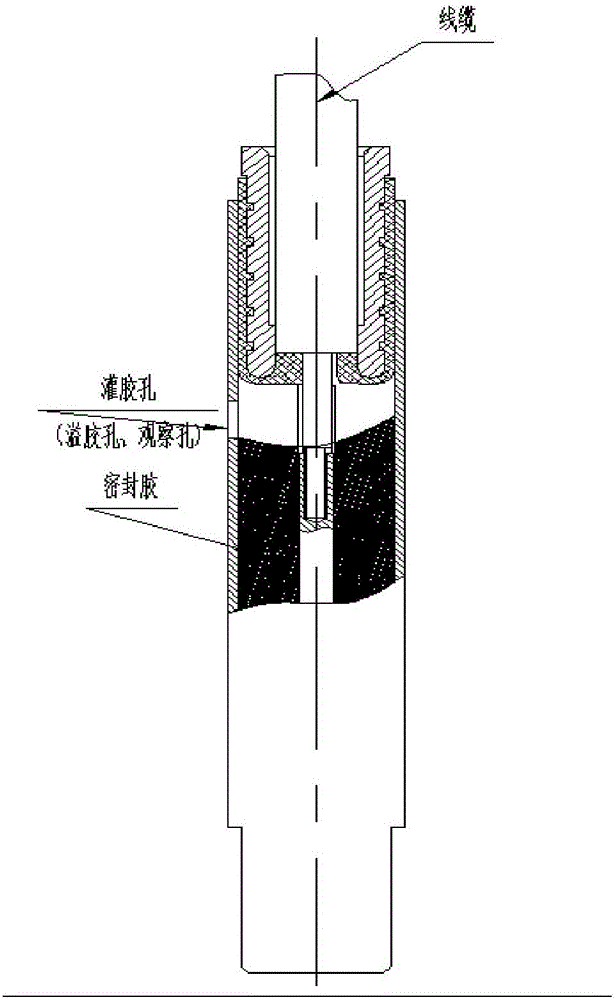

[0029] (4) Put the high-frequency contact piece vertically for curing, the excess glue overflows from the glue hole,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com