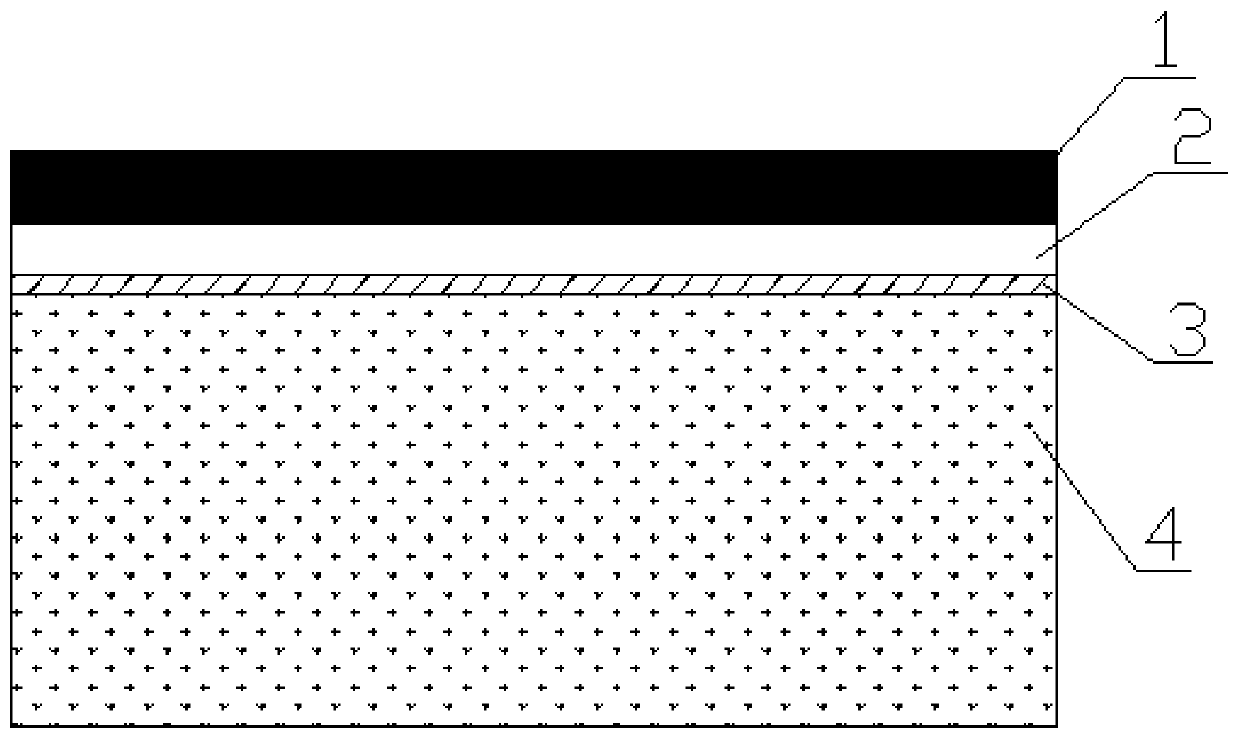

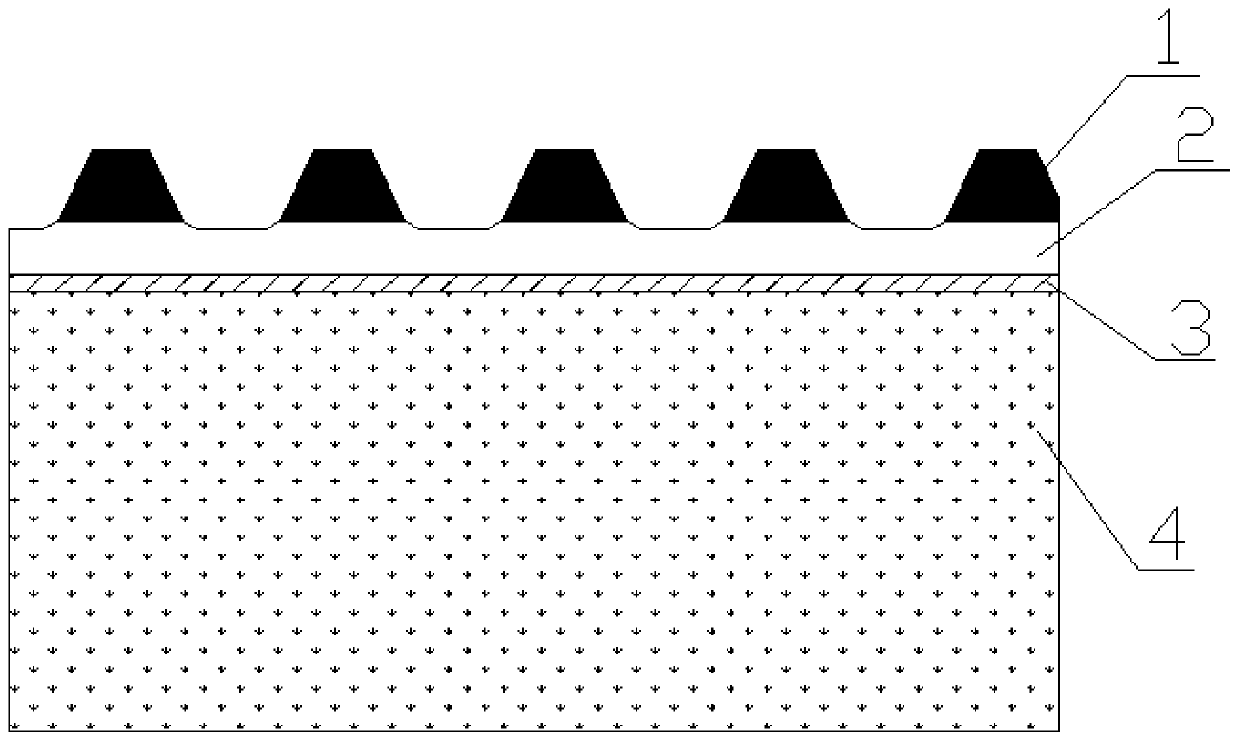

Insulating coating composition, preparation method of insulating coating, positive electrode sheet and lithium ion battery

A lithium-ion battery and insulating coating technology, applied in the field of materials, can solve problems such as short circuit, burr or falling material piercing the diaphragm, extrusion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

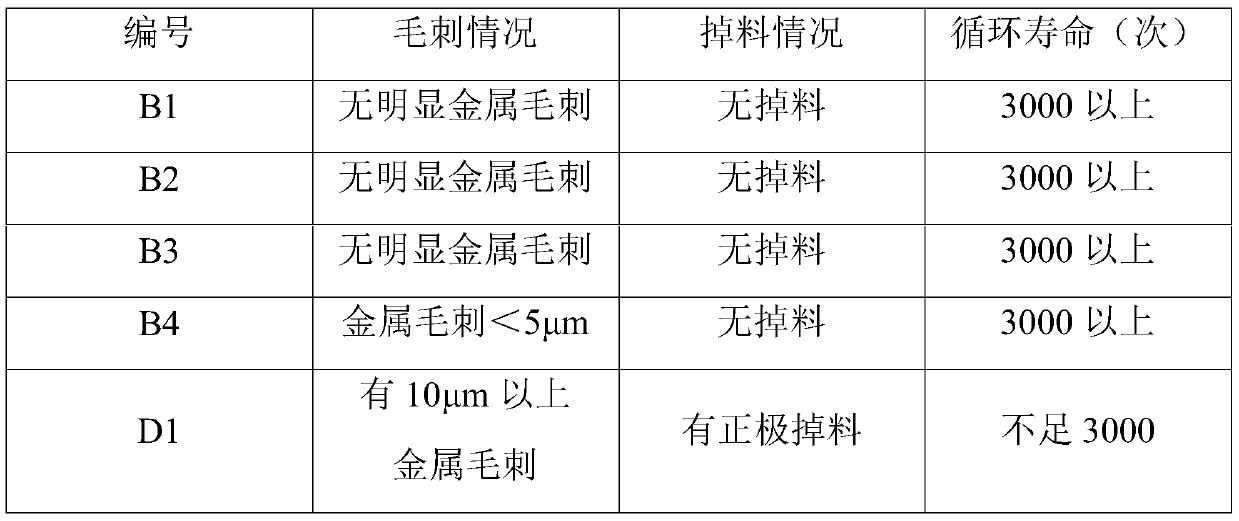

Examples

preparation example Construction

[0025] The present invention also provides a method for preparing an insulating coating, wherein the insulating coating is prepared from the above-mentioned composition. The preparation method may be conventional mixing, for example, stirring and mixing directly.

[0026] Of course, in a more preferred embodiment, in order to further improve the punching performance of the prepared insulating coating after being applied to the lithium-ion battery, the preparation method includes:

[0027] 1) mixing the adhesive with the first part of the solvent to prepare the glue;

[0028] 2) mixing the glue prepared in step 1) with the insulating material to prepare the coating material;

[0029] 3) mixing the coating blank prepared in step 2) with the second part of solvent to obtain an insulating coating;

[0030] Wherein, based on the total weight of the solvent, the amount of the first part of the solvent used is 80% by weight to 90% by weight, and the amount of the second part of sol...

preparation example 1

[0042] 1) 2% by weight of polyvinylidene fluoride and 60% by weight of N-methylpyrrolidone were placed in a blender and stirred for 180 minutes to prepare glue;

[0043] 2) Place the prepared glue at a temperature of 25°C for 300 minutes to mature;

[0044] 3) After adding 30% by weight of alumina to the above-mentioned cured glue, stir for 300min to prepare the coating blank;

[0045] 4) Add 8% by weight of N-methylpyrrolidone to the coating raw material prepared in step 3) and stir evenly to obtain a mixture M1;

[0046] 5) Pass the mixture M1 prepared in step 4) through a 150-mesh sieve to obtain an insulating coating A1.

preparation example 2

[0048] Prepare according to the preparation method of Preparation Example 1, the difference is that the aluminum oxide is replaced with boehmite, the amount of polyvinylidene fluoride is 3% by weight, and the amount of boehmite is 40% by weight. In step 1), N - The amount of methylpyrrolidone used is 50% by weight, and the amount of N-methylpyrrolidone used in step 4) is 7% by weight to obtain an insulating coating A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com