Device for testing performance of high-sensitivity infrared remote sensors

A high-sensitivity, testing device technology, applied in the direction of instruments, signal transmission systems, non-electrical signal transmission systems, etc., can solve the problem that the accuracy of temperature measurement and temperature control cannot meet the testing requirements of infrared remote sensors, and achieve the reduction of atmospheric heat transfer and disturbance Interference, temperature control and temperature measurement with high precision and great adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

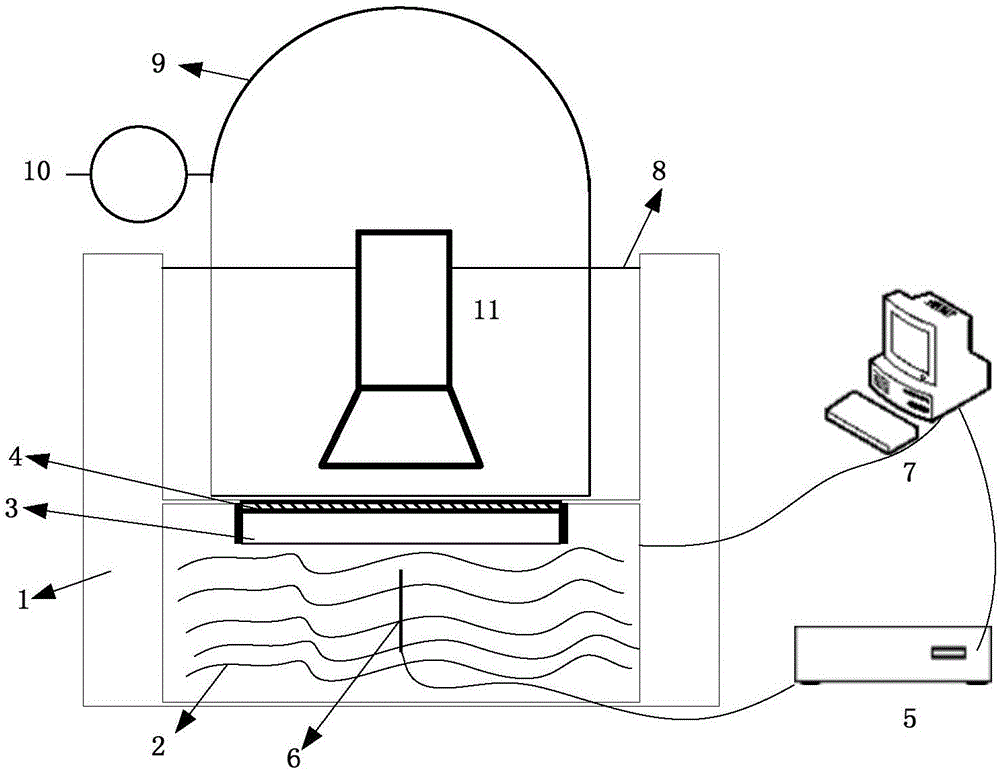

[0016] Attached below figure 1 The present invention is described in further detail with specific examples.

[0017] A high-sensitivity infrared remote sensor performance test device can be divided into several parts: temperature measurement and temperature control module, radiation source module and related auxiliary equipment. The specific composition and requirements of each part are as follows, as follows: figure 1 Shown:

[0018] The radiation source module is composed of a liquid tank 1 , a liquid working medium 2 and a radiation source 3 . The liquid tank 1 is used to hold the liquid working medium 2, the radiation source 3 is fixed in the liquid tank 1, and there are heaters on the bottom and surroundings of the liquid tank 1 for heating (or cooling) the liquid working medium 2. The radiation source 3 is a uniform copper plate or other metal plate or alloy plate with a specific heat capacity ≥ 400J / (kg·℃). The caliber of source 3 is designed according to the entranc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific heat capacity | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com