Rapid evaluation method for hydraulic friction resistance of pipelines

A technology of hydraulic friction resistance and evaluation method, which is applied in special data processing applications, instruments, electrical digital data processing, etc. The effect of improving engineering quality, measurement and calculation convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

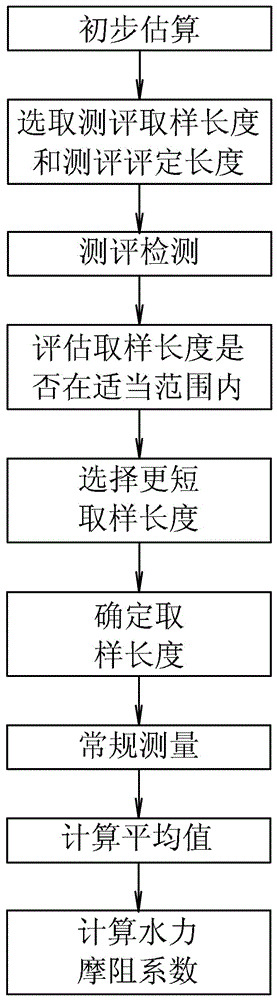

Method used

Image

Examples

Embodiment 1

[0046] This embodiment is a rapid evaluation method for pipeline hydraulic friction. The basic idea of the method is to introduce the (machined) surface roughness in machining into the detection of the inner wall surface of the water conservancy pipeline as the hydraulic friction coefficient of the pipeline k use.

[0047] The existing method is based on R q The values represent equivalent roughness values and give k ≈5 R q , k ≈3 R q , k ≈1.6 R q and other calculation methods.

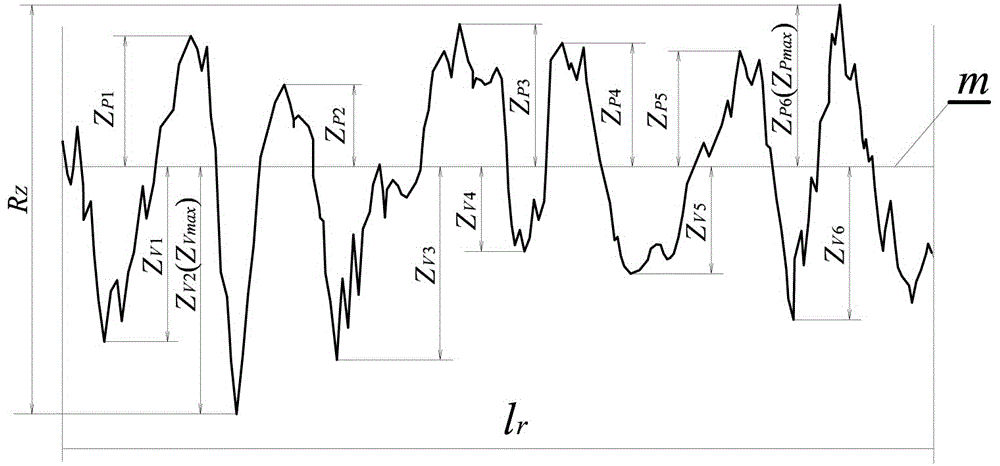

[0048] In this example, the maximum height value of the roughness profile is used R z ,Make R z ≈ k . Table 1 gives R a , R z , R q The experimental results are compared. It can be seen from the 1-5 sets of data in the table that, R z ≈ k , with 5 R q compared to, R z value closer to k value, and R z The definition and equivalent roughness k The physical meaning of is closer, and it can better represent the influence of the roughness of the inner wall of the pi...

Embodiment 2

[0087] This embodiment is an improvement of the first embodiment, and it is about the sampling length of the first embodiment lr or measure length ln Corresponding R a and R z refinement of the range. The sampling length described in this example lr or measure length ln Corresponding R a and R z The ranges are as follows:

[0088] R a ≤10 microns, lr 2.5mm, ln 12.5 mm; 10 microns R a ≤80 microns, lr 8mm, ln is 40mm;

[0089] R z ≤50 microns, lr 2.5mm, ln 12.5 mm; 50 microns R z ≤200 microns, lr 8mm, ln is 40mm.

[0090] Expressed in form as:

[0091] Table 2 R a Roughness sample length of value

[0092]

[0093] table 3 R z Roughness sample length of value

[0094]

[0095] Table 4 and Table 5 are the specifications of machining surface roughness, and the roughness sampling length recommended in the Chinese National Standard (GB / T 10610 2009). The selection of sampling length has a great influence on the measurement results of roughness...

Embodiment 3

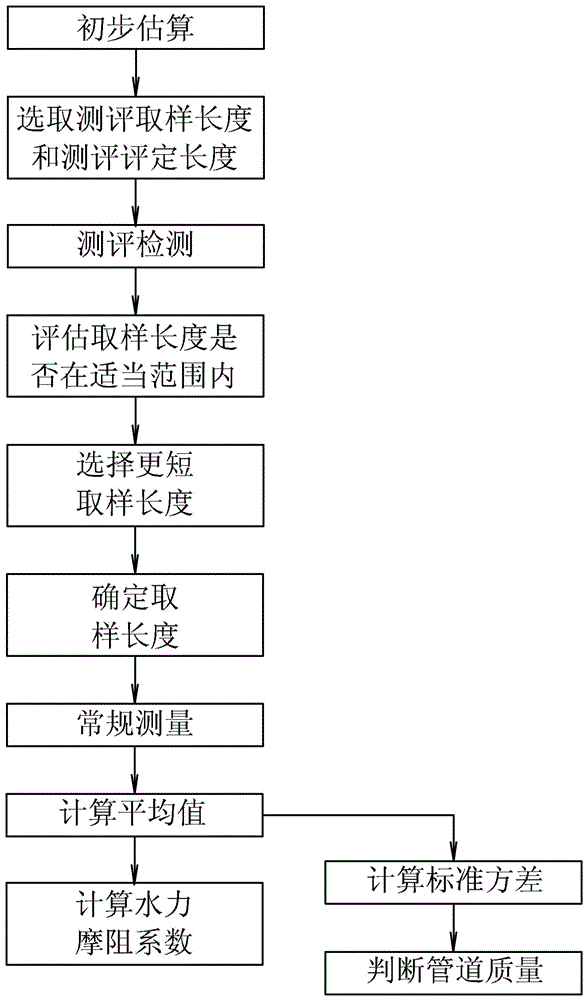

[0101] This embodiment is an improvement of the above-mentioned embodiment, which is calculated by using the above-mentioned embodiment R a , R z The method for evaluating the quality of the inner wall of the pipeline, the process is shown in image 3 Shown:

[0102] Set after the step of calculating the average value: the step of calculating the standard deviation and the step of judging the quality of the pipeline:

[0103] Steps to calculate standard deviation:

[0104] ,

[0105] ;

[0106] Steps for Judging Pipeline Quality: Used to calculate by formula R a and R z coefficient of dispersion cv Ra , cv Rz :

[0107] ,

[0108] ;

[0109] and judge cv Ra , cv Rz Is it less than the discrete coefficient cv If it is "Yes", it means that the measured pipe is uniform, otherwise it means that the measured pipe fittings are not lined with the same material, or the production quality of some pipe fittings is not up to standard.

[0110] In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com