Method and device for calculating equivalent minable thickness ratio of coal mine goaf for overhead transmission line

An overhead transmission line and calculation method technology, applied in the field of calculation method and device of the effective mining thickness ratio, can solve the problems such as the inability to reflect the severity of the surface deformation, lack of theoretical basis, safety hazards, etc., and achieve wide applicability and calculation theory. Well-founded, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1: The basic occurrence of the overlying rock and soil layer in the coal mining face of a goaf is shown in Table 1, and the thickness of the mined coal seam is 11.0m. Now it is necessary to calculate the equivalent mining thickness ratio of this place, evaluate the degree of influence on the transmission line, and put forward suggestions on whether the line can be built here.

[0052] Table 2: Layer parameters of the overlying rock and soil layer

[0053]

[0054] 1. Calculate the equivalent thickness of each rock and soil layer above the goaf

[0055] Taking loess as the standard medium, the actual thickness of each rock-soil layer overlying the rock-soil layer is converted to the equivalent thickness corresponding to the standard medium.

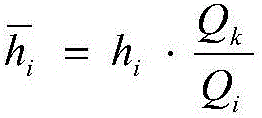

[0056] Substitute the actual thickness and lithology coefficient parameters of each layer in Table 2 into the formula Calculate the equivalent thickness of each layer as shown in Table 3.

[0057] 2. Calculate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com