Boiler ash-blowing optimization system and optimization method thereof

A technology of boiler soot blowing and optimization method, applied in the field of boiler soot blowing, can solve the problems of air preheater blockage, affecting the safe and economic operation of the unit, and soot blower accidental shutdown.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

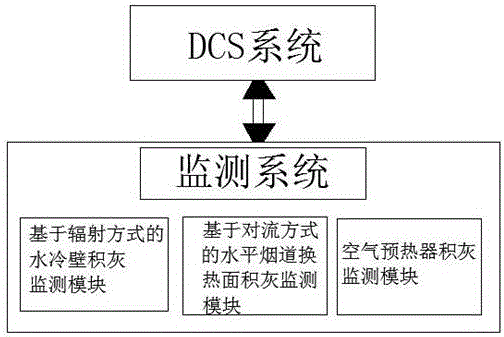

[0050] figure 1 A specific embodiment of the present invention is shown: a boiler soot blowing optimization system, including a DCS system and a monitoring system, the DCS system and the monitoring system are connected in communication, and the monitoring system includes a radiation-based water wall ash deposition monitoring module, based on Convection-type horizontal flue heat exchange area ash monitoring module and air preheater ash monitoring module.

[0051] An optimization method for a boiler soot blowing optimization system, comprising the following steps:

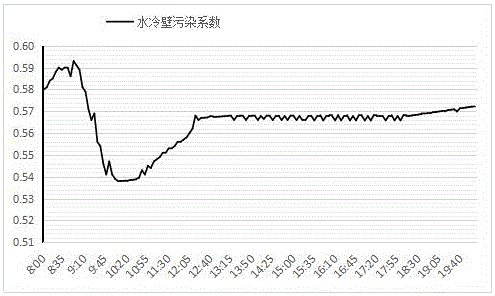

[0052] 1) The ash accumulation monitoring module of the water wall based on the radiation method is used to establish the ash accumulation monitoring model of the water wall based on the radiation method;

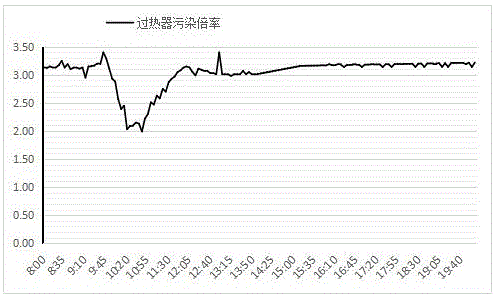

[0053] 2) Based on the ash monitoring module of the heat transfer area of the horizontal flue based on the convection method, the ash monitoring model of the heat transfer area of the horizontal flue based on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com