Optical fiber cable provided with non-central strengthening parts

A strength member and non-center technology, which is applied in the field of non-central strength member optical cables, can solve problems such as difficult stripping and welding, affecting construction efficiency, and large diameter of optical cables, and achieves the effects of easy wiring, improved laying efficiency, and shortened construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

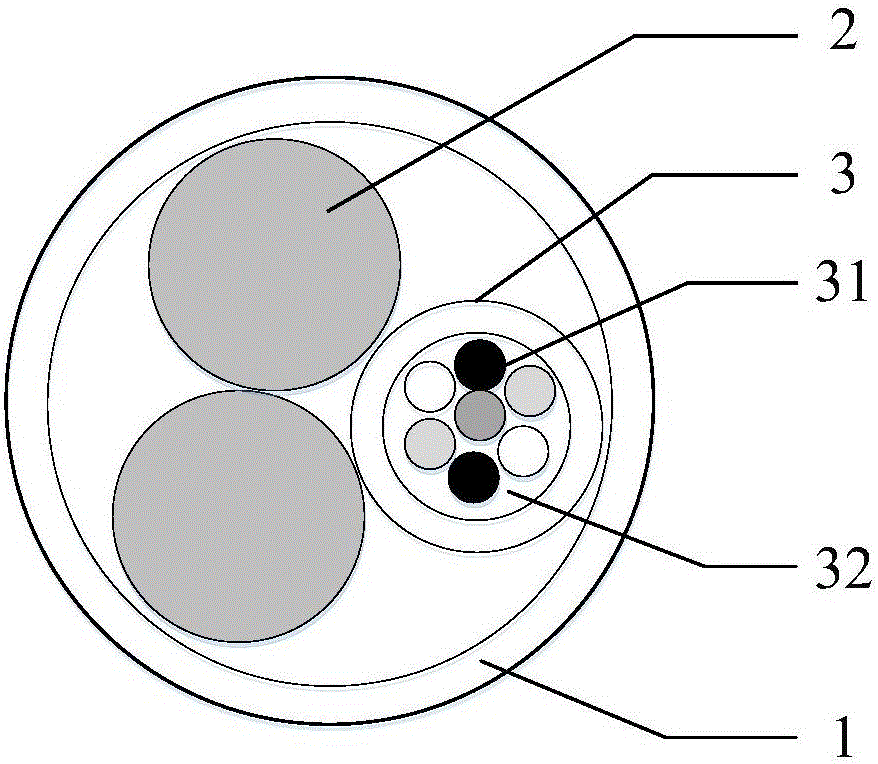

[0025] see figure 1 As shown, the present invention provides a non-central strength member optical cable, including a sheath layer 1 , a strength member 2 and a loose tube 3 .

[0026] The sheath layer 1 is sleeved on the strength member 2 and the loose tube 3, there are at least two strength members 2, and at least one loose tube 3, and the overall cross section of the optical cable is circular. Both the loose tube 3 and the reinforcement 2 are located in the sheath layer 1 , wherein each reinforcement 2 is located in a non-central position in the sheath layer 1 . In the present invention, there is one loose tube 3 and two reinforcing members 2. Since the present invention adopts the non-central reinforcing member structure, only one loose tube 3 is arranged in the optical cable, instead of multiple loose tubes surrounding and strengthening the conventional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com