Synchronous generator rotor winding turn-to-turn short circuit diagnosis method based on double coils

A technology for synchronizing generator and rotor windings, which is applied in electrical winding testing, motor generator testing, and electrical measurement. Magnetic flux and other problems, achieve high anti-interference ability and diagnostic accuracy, and prevent the deterioration of inter-turn short circuit faults in synchronous generator rotor windings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0031] A specific embodiment of the present invention comprises the following steps:

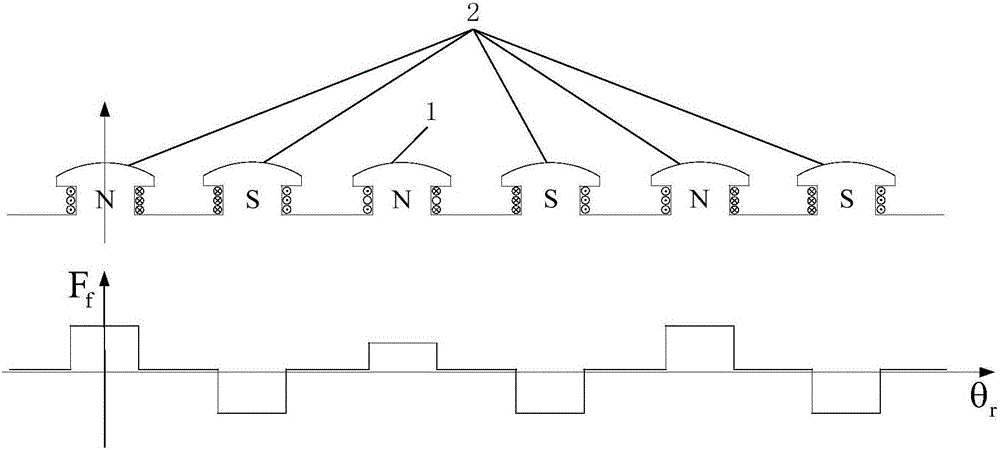

[0032] Two U-shaped detection coils are installed in the radial direction at a certain distance on the stator core section inside the synchronous generator. The output ports of the two U-shaped detection coils are connected in parallel with high resistance resistors with the same resistance value, and the two U-shaped detection coils are collected by the data acquisition device. The voltage signal of the output port of the U-shaped detection coil;

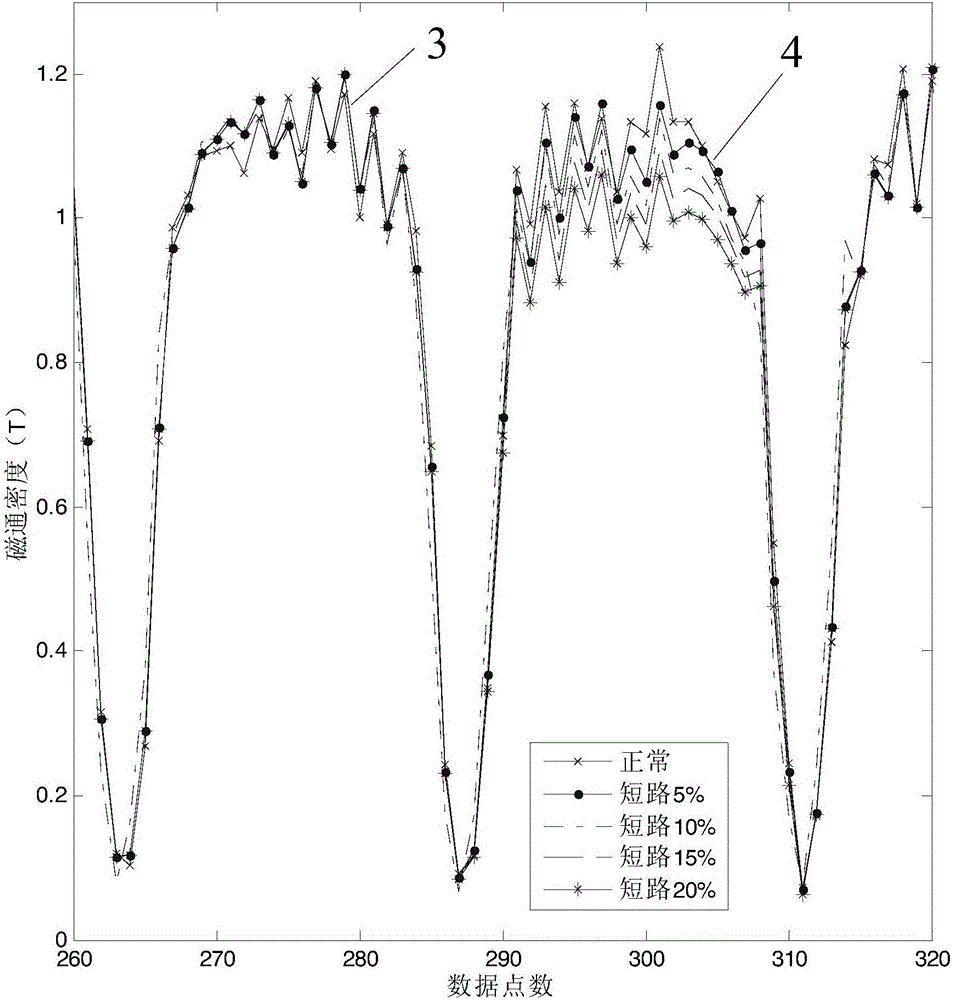

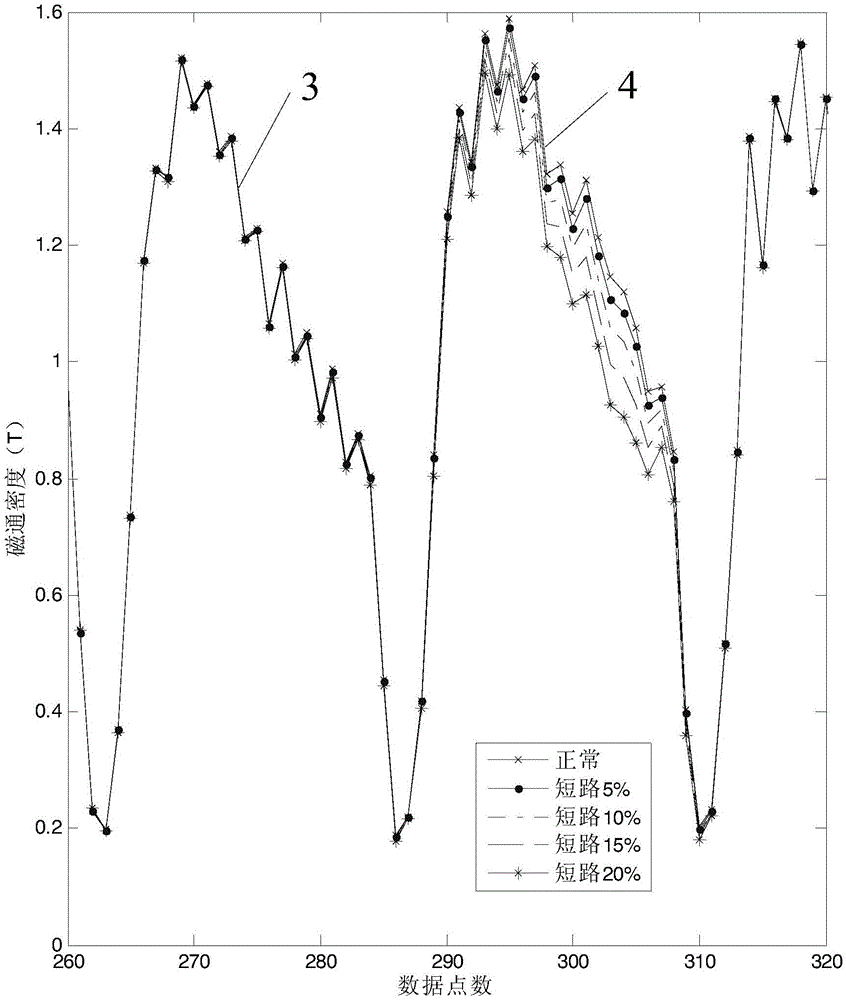

[0033] During the operation of the generator, the voltage signals at the outlets of the two U-shaped detection coils collected by the data acquisition device are processed in real time, and the output voltages of the two U-shaped detection coils are differenced or added. When the result exceeds the set threshold , it is determined that the synchronous generator has an inter-turn short circuit fault in the rotor winding.

[0034] The distance bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com