Compressed sensing based turbine impeller ultrasonic phased array signal compression method

An ultrasonic phased array and compressed sensing technology, which is applied in the processing of detection response signals, analysis materials, instruments, etc., can solve problems such as the inability to fundamentally reduce the amount of sampled data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

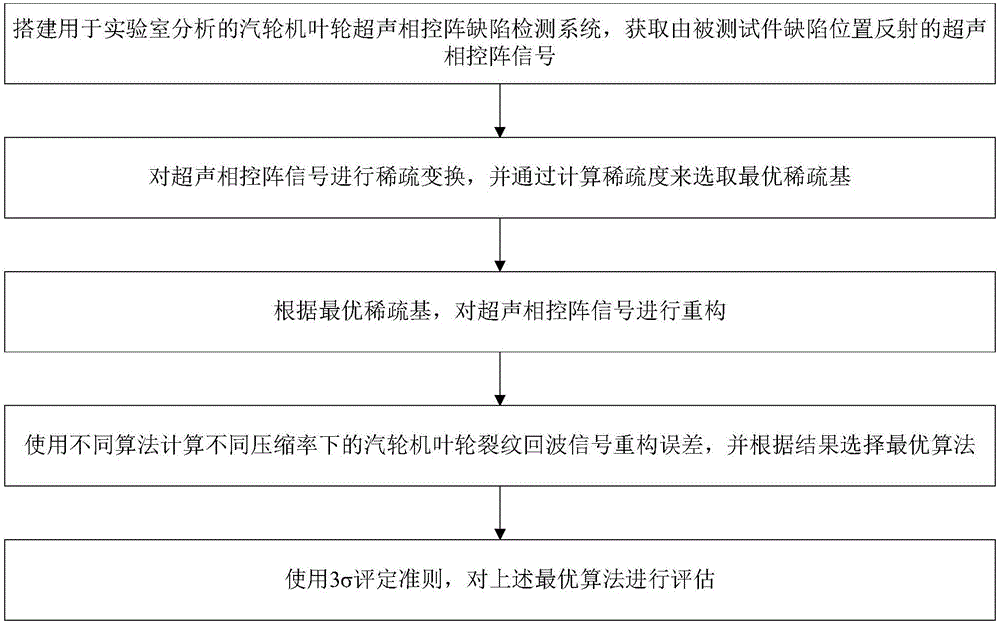

[0045] A compressive sensing based ultrasonic phased array signal compression method for steam turbine impellers, see figure 1 , the compression method includes the following steps:

[0046] 101: Build a steam turbine impeller ultrasonic phased array defect detection system for laboratory analysis, and obtain the ultrasonic phased array signal reflected by the defect position of the test piece;

[0047] 102: Perform sparse transformation on the ultrasonic phased array signal, and select the optimal sparse basis by calculating the degree of sparsity;

[0048] 103: According to the optimal sparse basis, use different algorithms to reconstruct the ultrasonic phased array signal;

[0049] 104: Use different algorithms to calculate the reconstruction error of the crack echo signal of the steam turbine impeller under different compression ratios, and select the optimal algorithm according to the results;

[0050] 105: Use the 3σ evaluation criterion to evaluate the above optimal a...

Embodiment 2

[0068] The scheme in embodiment 1 is introduced in detail below in conjunction with specific calculation formulas and examples, see the following description for details:

[0069] 201: Build a steam turbine impeller ultrasonic phased array defect detection system for laboratory analysis, and obtain the ultrasonic phased array signal reflected by the defect position of the test piece for subsequent analysis;

[0070] The detailed operation of this step is:

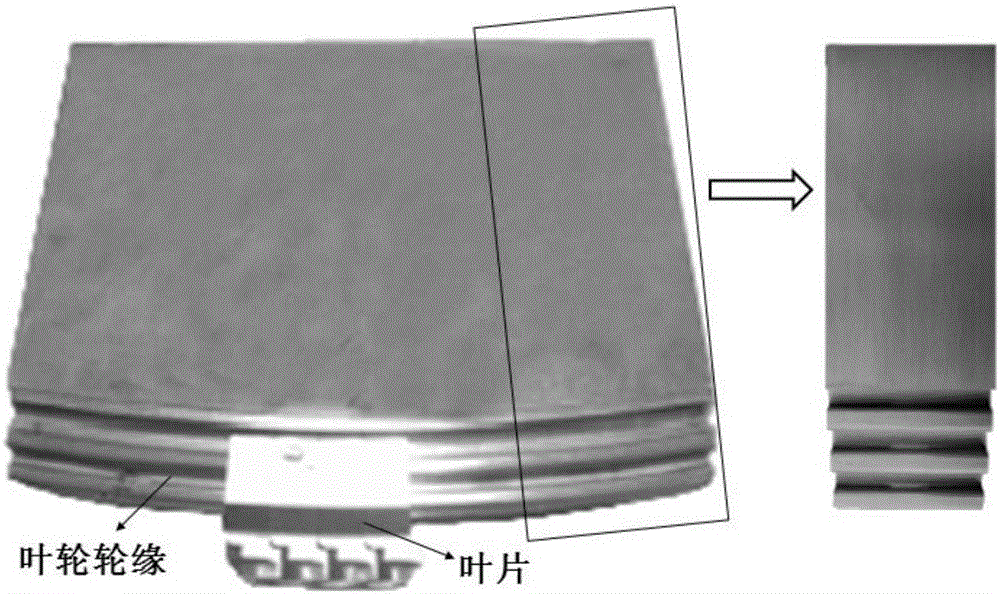

[0071] 1) The size of the impeller of the steam turbine is very large. For the convenience of laboratory research, a small part of the impeller of the steam turbine is cut off and a simulated test block of equal proportion is made. The material is 20# steel, as shown in Figure 2(a). As shown in Figure 2(b). Six crack defects were machined at the groove position using electric discharge (EDM) machining technology, and the crack size and angle are shown in Table 1.

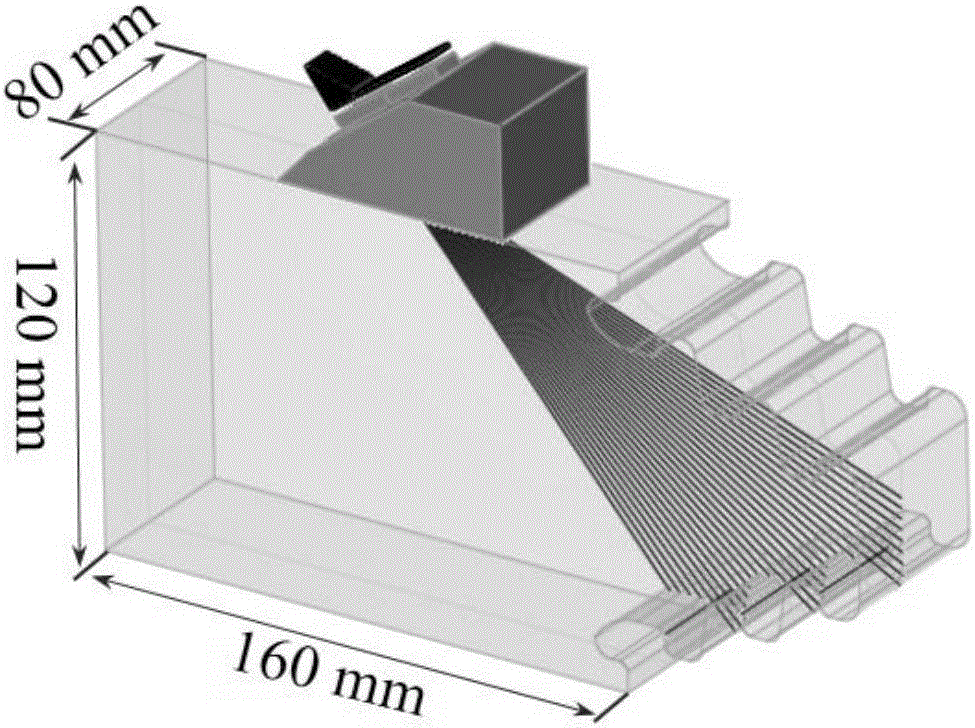

[0072] 2) Build an ultrasonic phased array defect detecti...

Embodiment 3

[0132] Below in conjunction with concrete test data, the scheme in embodiment 1 and 2 is carried out feasibility verification, see the following description for details:

[0133] The device parameters used in this embodiment are: a 64-element ultrasonic phased array probe with a center frequency of 5 MHz, the center distance of the array elements is 0.6 mm, the material of the test piece is 20# steel, and the AD sampling frequency is 100 MHz. The upper computer CPU is AMD AthlonX4 quad-core, 4GB memory, and the operating system is Windows 7 64bit.

[0134] 1) Take defect No. 2 as an example for follow-up analysis. The defect echo A-scan signal is shown in Fig. 4(a), and then a series of sparse transformations are performed on it, and the signal length N=1024 is selected.

[0135] 2) Perform discrete Fourier transform, discrete cosine transform, and discrete wavelet transform on the above signals respectively, and the results of the transform are shown in Figure 4(b), (c), and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com