Method for testing anti-cracking ability of paving interface of steel bridge deck slab and epoxy asphalt mixture

A technology of epoxy asphalt and steel bridge deck, which is applied in the direction of measuring device, analyzing materials, strength characteristics, etc., can solve the problems of destroying the integrity and continuity of the structure, corrosion of steel plates, shortening the service life of the road surface, etc., and achieves stable and reliable test results. , the equipment is simple and cheap, the test method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

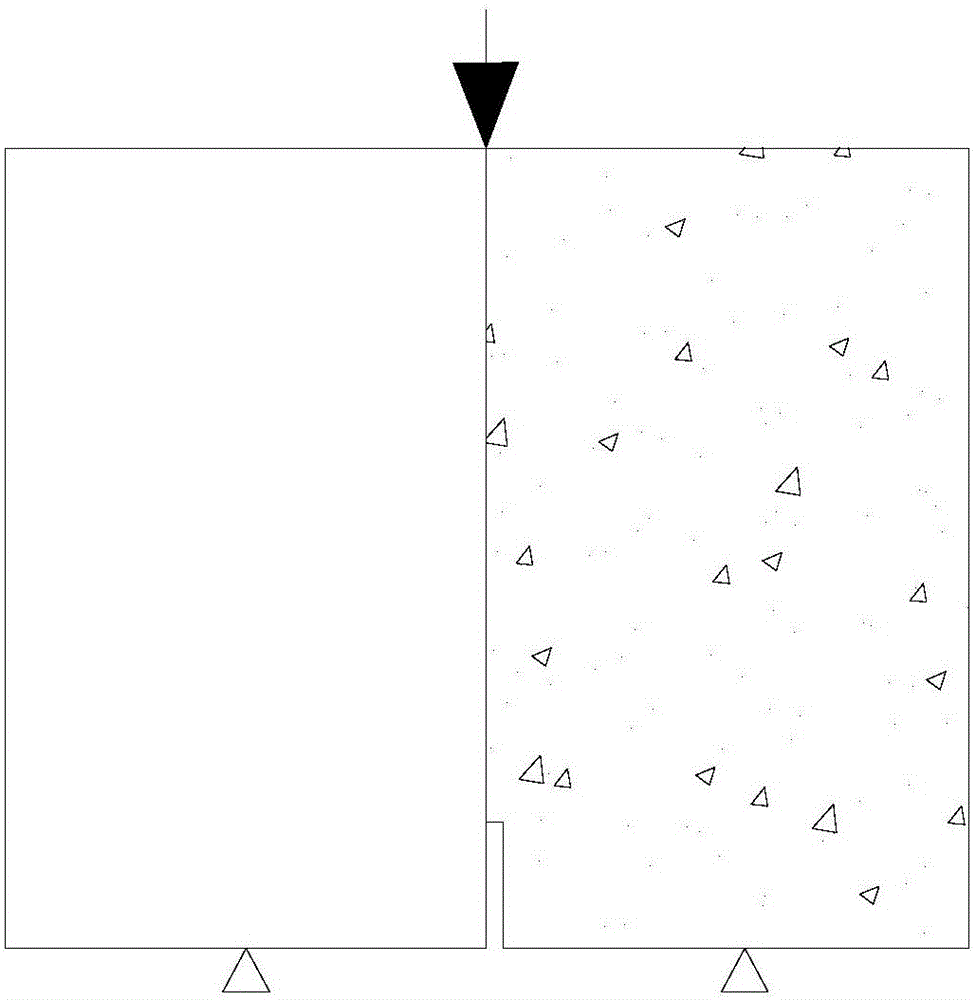

[0037] combine Figure 1 to Figure 4 , a method for testing the crack resistance of the steel bridge deck and epoxy asphalt pavement interface, the method steps are as follows:

[0038] Step 1. Slowly heat the epoxy asphalt mixture to be tested and pour it into the mold for molding. After the pouring is completed, place it at room temperature to cool. When the demoulding condition is reached, remove the mold and transfer the test piece out of it to obtain a single-sided edge prepreg. Cuboid beam specimens with gaps, such as figure 2 As shown, after demoulding, put the sample into a constant temperature box that reaches the experimental temperature, and keep the temperature at 45°C for 60 minutes. The bonding material between the steel bridge deck and the pavement interface uses If-type epoxy asphalt, and its main technical properties are shown in Table 1.

[0039] Table 1 Technical properties of bonding materials

[0040]

[0041] The asphalt pavement adopts epoxy aspha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com