Method for establishing gradient temperature field

A technology for establishing a method and a temperature field, which is applied in the field of fracture resistance testing of metal materials, can solve problems such as unpublished patents and unpublished reports, and achieve the effects of ensuring effectiveness, convenient operation, and airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

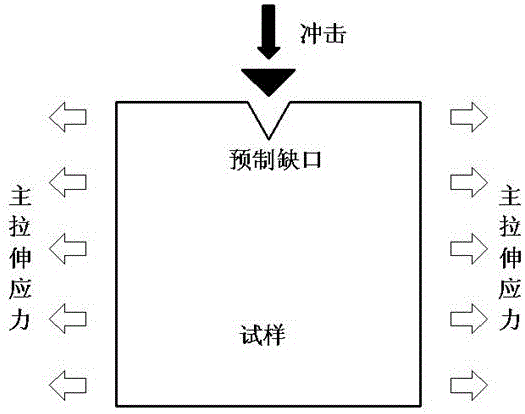

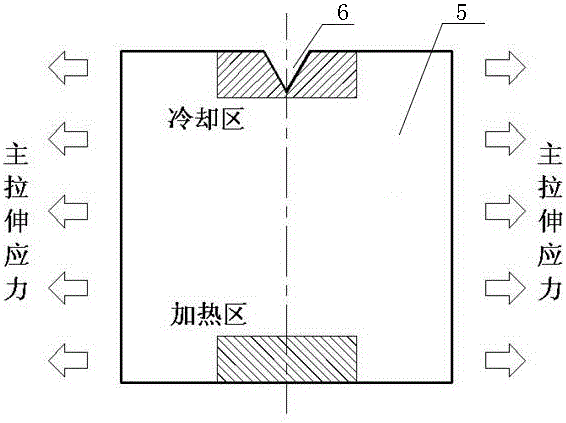

[0032] In the gradient temperature ESSO test, whether the gradient temperature field can meet the requirements of the standard specification will directly affect the validity of the test. The present invention mainly designs the establishment technology of the gradient temperature field based on this requirement.

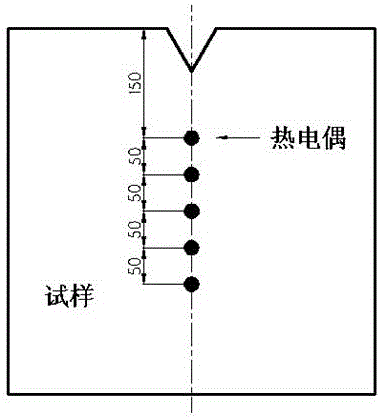

[0033] During the gradient temperature ESSO test, in order to form a gradient temperature field in the sample, it is necessary to cool one end of the sample and heat the other end at the same time; in order to ensure the validity of the results, the surface temperature field on both sides of the sample should be the same ; In addition, effective measurement of the temperature field should also be achieved. The solution adopted by the present invention for the technical problems in the above three aspects is: use a low-temperature tank and a cooling medium to cool the notch of the sample, in addition to forming the cold end of the gradient temperature field, it can al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com