Separately excited vibrating cylinder pressure sensor performance test method

A technology of pressure sensor and testing method, which is applied in the direction of calibration/testing of force/torque/power measuring instrument, instrument, measuring device, etc. Problems such as rough test results, to achieve high test efficiency, improve accuracy and reliability, and reliable test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

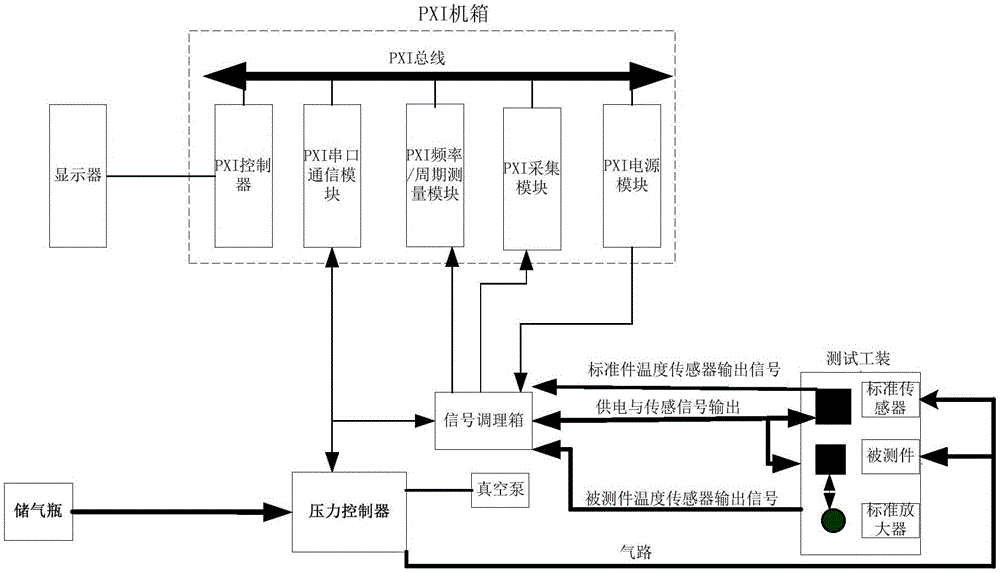

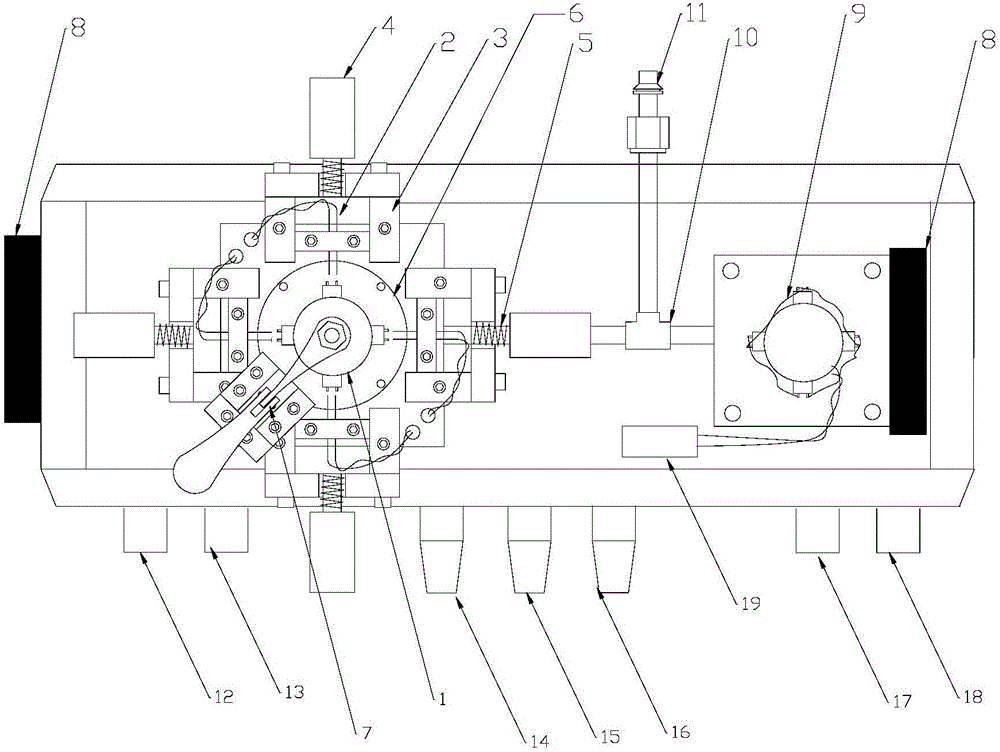

[0017] refer to figure 1 . According to the present invention, in the performance testing system of the externally excited vibrating cylinder pressure sensor, a vibrating cylinder pressure sensor is used as the standard pressure sensor, and the tested sensor as the tested part is connected between the standard pressure sensor and the standard amplifier to form A test fixture that is electrically connected to the test circuit of the tested sensor; the two-body spring probe is used for contact connection with the coil pin on the tested sensor, and a fixed base is used to electrically connect the test circuit with the mobile two-body spring probe. For the test piece, fix the tested sensor on the test fixture, and then apply the same working pressure to the tested sensor and the standard pressure sensor, starting from 0kPa, gradually increasing the pressure every 0.25kPa to the full scale, using signal conditioning The PXI data acquisition card in the box collects the output freq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com