Dangerous liquid metering system and metering and conveying method

A liquid measurement and dangerous technology, applied in the direction of volume measurement instruments/methods, liquid/fluid solid measurement, measurement capacity, etc., can solve the problems of high flammability, difficulty in ensuring accurate safety risks, etc., and achieve the effect of high-precision measurement and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

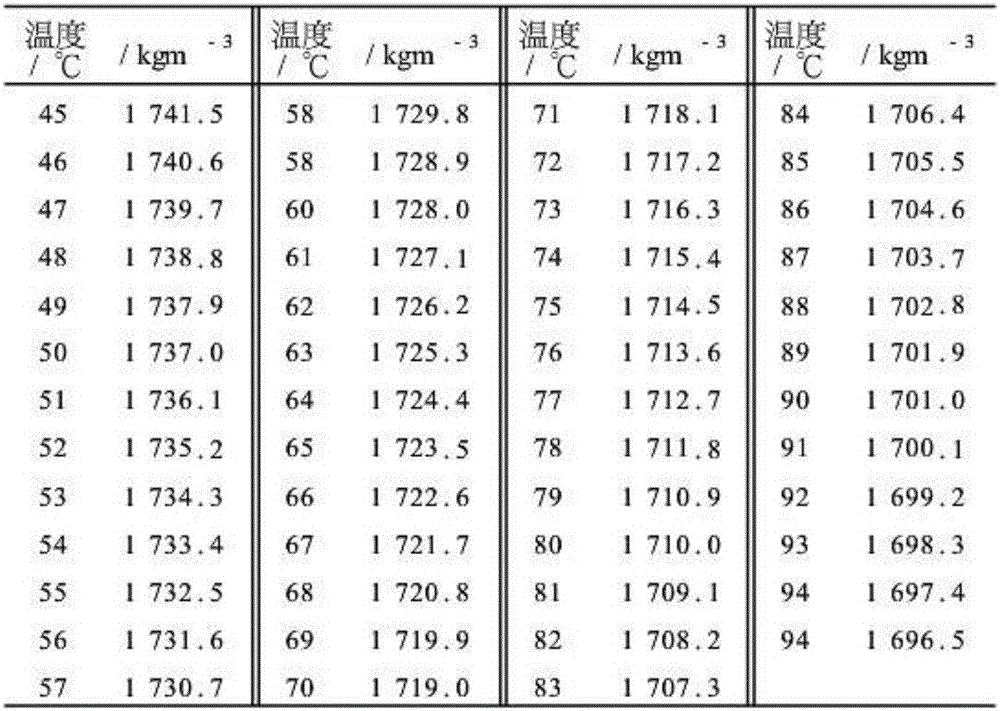

[0049] The dangerous liquid substance to be metered and transported is liquid yellow phosphorus (density about 1.73g / ml), and the protective fluid is deionized water (density about 1.0g / mL). Since the density of liquid yellow phosphorus is much higher than that of deionized water, when the two coexist, the water will float on it to isolate the air from the yellow phosphorus.

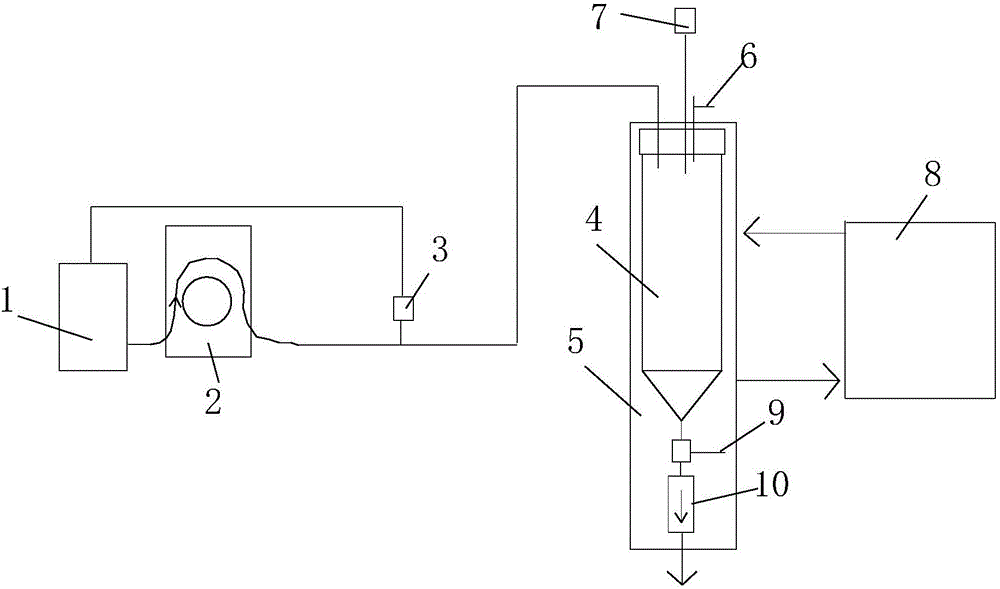

[0050] Such as figure 1 As shown, the system includes protection fluid storage tank 1, metering pump 2, safety valve 3, metering container 4, heating jacket 5, overflow valve 6, temperature, liquid level and pressure transmitter module 7, heating device 8. The three-way valve 9 and the first one-way valve 10;

[0051] The workflow of this system is as follows:

[0052] (1) The overflow valve 6 is opened, and the three-way valve 9 is closed;

[0053] (2) The user injects deionized water about 1 / 4 of its volume into the metering container 4;

[0054] (3) the user puts the yellow phosphorus into the met...

Embodiment 2

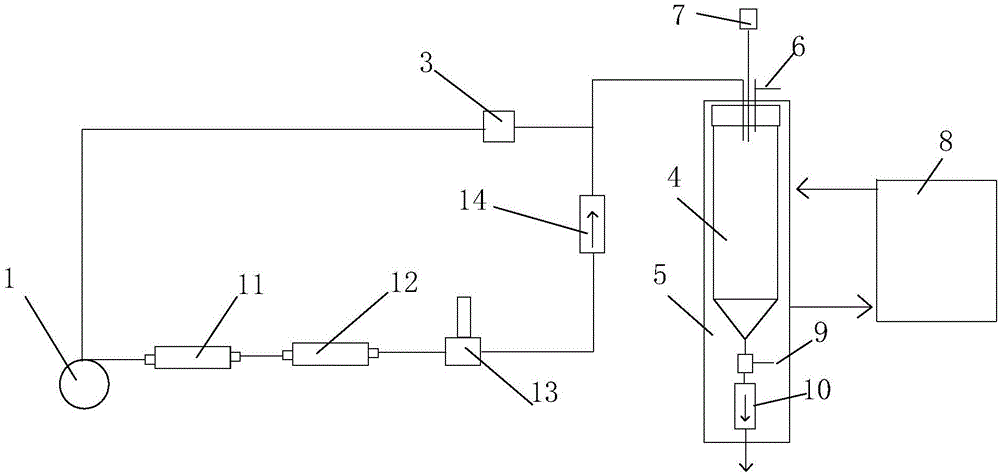

[0060] The dangerous liquid substance to be metered and transported is tert-butyllithium (density about 0.66g / ml), and the protective fluid is argon (density about 1.78mg / mL). Since the density of liquid tert-butyl lithium is much greater than that of argon, when the two coexist, argon will float on it to isolate the air from tert-butyl lithium.

[0061] Such as figure 2 As shown, the liquid metering system includes a protective fluid storage tank 1, a gas filter 11, a mass flow meter 12, an electromagnetic stop valve 13, a second one-way valve 14, a safety valve 3, a metering container 4, and a heating jacket 5 , overflow valve 6, temperature, liquid level and pressure transmitter module 7, heating device 8, three-way valve 9 and first one-way valve 10.

[0062] The workflow of this system is as follows:

[0063] (1) The overflow valve 6 is opened, and the three-way valve 9 is closed;

[0064] (2) A certain amount of argon gas is injected into the metering container 4 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com