Double-layer abrasion-resistant bent pipe for concrete conveying

A concrete, double-layer technology, applied in elbows, siphons, pipe components, etc., can solve the problems of low service life, high labor costs, and high costs, reduce demand and labor costs, reduce production costs, and ensure service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

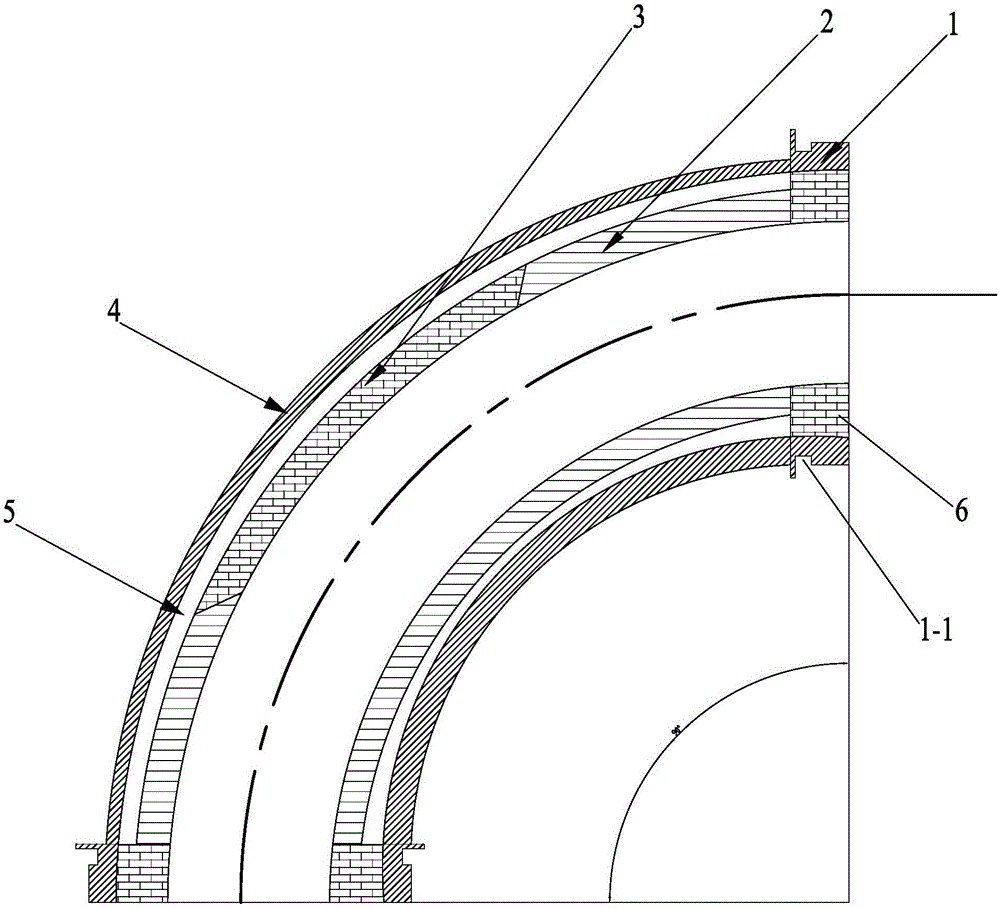

[0012] figure 1 Among them, including standard flange 1, ring groove 1-1, inner tube 2, wear-resistant part 3, protection tube 4, filler 5, plug 6, etc.

[0013] Such as figure 1 As shown, the present invention is a double-layer wear-resistant elbow pipe for concrete transportation, including a protective tube 4 with a certain curvature, and an inner bile tube 2 is arranged in the protective tube 4, and the inner bile tube 2 and the protective tube 4 A filling space is formed between them, and fillers 5 are set in the filling space, standard flanges 1 are respectively set at both ends of the protection tube 4, and plugs 6 are fixedly set on the inner wall of the standard flange 1, and the two ends of the inner bile pipe 2 are connected with the corresponding plugs. 6 against contact, the neck of the inner bile duct 2 is provided with a not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com