Vacuum valve

A technology for vacuum valves and valve openings, applied in sliding valves, valve details, valve devices, etc., can solve problems such as long working hours and relying on operator experience, and achieve the effects of compact structure, low noise, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

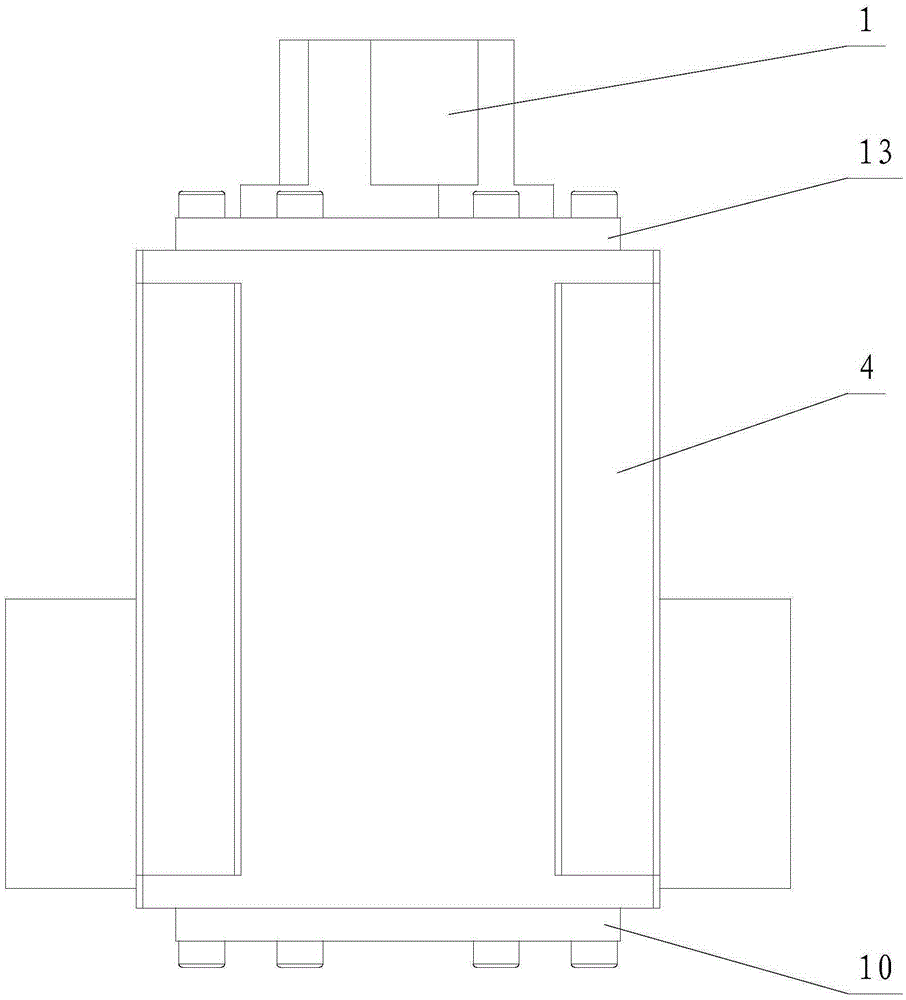

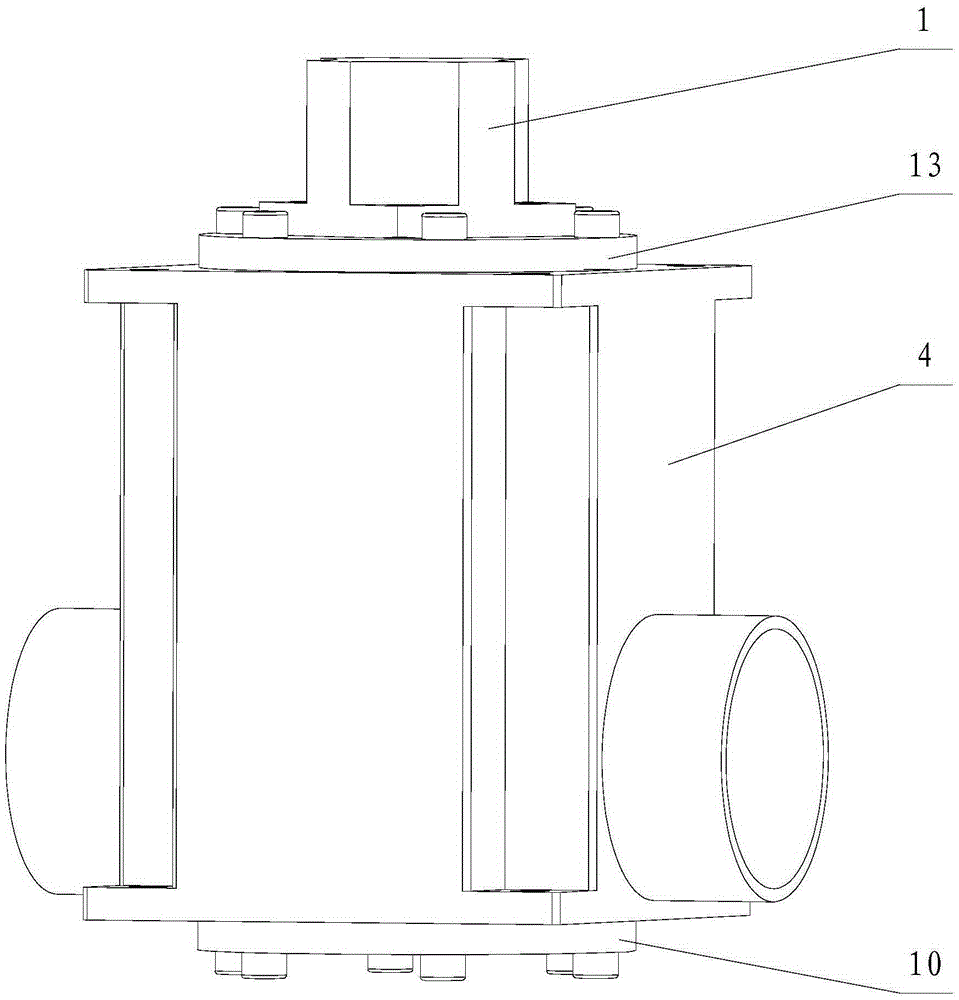

[0016] Such as Figure 1~3 As shown, the present invention includes a linear stepper motor 1, an upper valve cover 13, a valve body 4, a telescopic screw rod 5, a valve seat 7, a lower valve cover 10 and a proximity sensor, wherein the valve body 4 is made of stainless steel, and the nominal The diameter can be 15, 25, 40, 50 and other specifications; the upper and lower ends of the valve body 4 are arranged with valve body sealing rubber rings 9, and the upper valve cover 13 and the lower valve cover 10 are respectively fixed by fastening screws 3 The upper and lower ends of the valve body 4 are sealed with the valve body 4 through the valve cover sealing rubber ring 8 and the valve body sealing rubber ring 9 .

[0017] The linear stepping motor 1 is used as an actuator, and is fixed on the top of the upper valve cover 13, and the seam adopts a small interf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com